Samsung Electro-Mechanics Expected to Hold 15-18% Market Share This Year

Rapid Growth from 4% Market Share in 2022

Achieving 1 Trillion Won in Sales This Year Seems Feasible

Continued Consideration of Expansion at Philippine Factory

Samsung Electro-Mechanics is rapidly closing the gap with Japan's traditional powerhouses in the automotive multilayer ceramic capacitor (MLCC) market, steadily increasing its market share. Over the past two years, Samsung Electro-Mechanics has expanded its position by more than 10 percentage points and is expected to enter the 'Top 3' in the global automotive MLCC market this year. To respond to the trend of automotive electrification driven by the growth of future car industries such as autonomous driving and electric vehicles, Samsung Electro-Mechanics is also considering production expansion plans, including utilizing its factory in the Philippines.

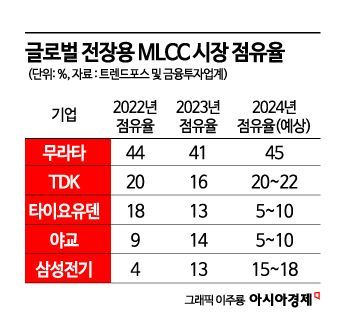

According to industry sources on the 30th, Samsung Electro-Mechanics is estimated to record about 15-18% market share in the global automotive MLCC market this year. This marks a rise to third place compared to last year.

The top spot is expected to be maintained by Japan's Murata, with an overwhelming market share of 45%, while TDK is projected to hold second place with a 20-22% share.

Samsung Electro-Mechanics has steadily narrowed the gap with traditional Japanese players in the automotive MLCC market. According to market research firm TrendForce, Samsung Electro-Mechanics' market share in automotive MLCC was only 4% in 2022 but surged to 13% last year. During the same period, Japanese companies saw their shares decline: Murata dropped from 44% to 41%, TDK from 20% to 16%, and Taiyo Yuden from 18% to 13%.

Automotive MLCCs require higher quality standards such as product lifespan and technical reliability compared to IT product MLCCs because they are directly linked to passenger safety. The entry barrier is high. In particular, since they must maintain performance under high temperature and high pressure environments, automotive MLCCs are priced about 5 to 10 times higher than IT MLCCs.

In this market, Samsung Electro-Mechanics has strengthened its competitiveness by actively expanding its premium lineup, including launching the world's highest capacity MLCCs. As a result, despite market stagnation, it is evaluated to have succeeded in diversifying its customer base. It is further strengthening its position in the MLCC markets for infotainment, advanced driver-assistance systems (ADAS), and powertrain rather than general-purpose products.

Samsung Electro-Mechanics is also expected to smoothly achieve its goal of '1 trillion KRW in automotive MLCC sales' this year. Its automotive MLCC sales increased from about 500 to 600 billion KRW in 2022 to over 800 billion KRW last year, and are expected to surpass 1 trillion KRW this year.

Attention is also focused on whether mass production of automotive MLCCs will be further expanded through factory expansions in the future. Currently, Samsung Electro-Mechanics produces automotive MLCCs in Busan and Tianjin, China. In the case of the Busan plant, the storage capacity of the raw material building, which stocks barium titanate (BT) powder, a raw material for MLCCs, is planned to be doubled by 2027 and tripled by 2030. This strategy aims to internalize raw material supply and expand the proportion of high-end products as the importance of raw material procurement increases due to the high performance of MLCCs.

The Tianjin facility is three times the size of the Busan plant and plans to produce a diverse lineup of automotive MLCCs through future investment expansion. MLCCs are classified by size such as 1005, 1608, and 3225; for example, a product measuring 3.2mm in width and 2.5mm in length is classified as 3225. Additionally, MLCC types are further subdivided by voltage and capacitance, and Samsung Electro-Mechanics has already developed 13 types of automotive MLCC products.

Samsung Electro-Mechanics is also continuously reviewing plans to produce automotive MLCCs at its Laguna plant in the Philippines. Currently, the Philippine factory mainly produces MLCCs used in IT products such as smartphones and laptops.

Kim Sowon, a researcher at Kiwoom Securities, said, "Samsung Electro-Mechanics' automotive MLCC shipments in the second quarter increased by double digits," adding, "With supplementary investments focused on high value-added products, including preparations for initial mass production of automotive MLCCs utilizing the Philippine base, an annual capacity expansion of about 10% is expected."

Meanwhile, the automotive MLCC market is rapidly growing due to the expansion of related markets such as automotive electrification, electric vehicles, and autonomous vehicles. While about 1,000 MLCCs are used in smartphones, more than 3,000 are installed in cars, and electric vehicles require up to 20,000 MLCCs. The global automotive MLCC market size is expected to grow from $2.9 billion (about 3.8 trillion KRW) in 2023 to $4.0 billion (about 5.3 trillion KRW) in 2026, and reach $12.3 billion (about 16.4 trillion KRW) by 2040.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.