A high-strength, high-elongation alloy design method applying spinodal strengthening has been devised domestically.

Elongation is a concept referring to the length of heated metal, and designing alloys with both high strength and high elongation has been considered a challenging task, like a spear and shield that are difficult to reconcile.

However, with the development of an alloy design method that satisfies both properties, it is evaluated that a green light has been turned on for the development of next-generation high-performance materials.

The National Research Foundation of Korea announced on the 12th that a joint research team consisting of Professors Kim Hyung-seop and Heo Yun-wook from Pohang University of Science and Technology and Dr. Farahnaz Haftlang from Northwestern University in the United States succeeded in designing a medium-entropy alloy that simultaneously increases strength and elongation (the value expressed as a percentage obtained by dividing the difference between the maximum length of the heated metal and the original length by the original length), solving a long-standing challenge in structural materials.

Medium-entropy alloys are characterized by mixing several elements in relatively equal proportions without a dominant element, exhibiting high mixing entropy. They have the advantage of freely adjusting the types and amounts of alloying elements to improve strength, ductility, corrosion resistance, and electromagnetic properties of the alloy.

Medium-entropy alloys based on iron (Fe) are attracting attention for their excellent properties such as high strength, elongation, and corrosion resistance.

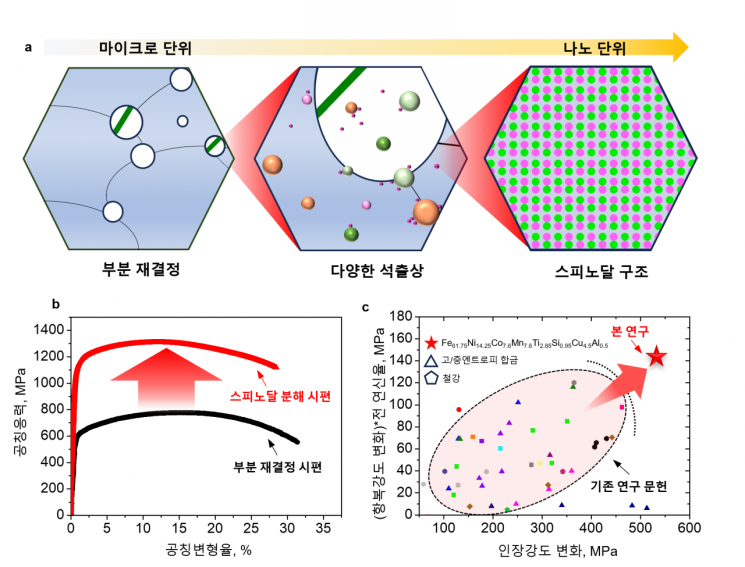

Schematic diagram of the microstructure and tensile properties of the medium-entropy alloy developed by the research team. Provided by the National Research Foundation of Korea.

Schematic diagram of the microstructure and tensile properties of the medium-entropy alloy developed by the research team. Provided by the National Research Foundation of Korea.

However, to overcome the low yield strength (the maximum stress that can be applied before deformation occurs), precipitation strengthening must be used. Precipitates differ in matrix structure and coherence, which limits elongation. Additionally, the complex and delicate heat treatment process required to obtain precipitates hinders the full utilization of medium-entropy alloys.

For this reason, some have raised the need for a new strengthening mechanism that increases yield strength without reducing elongation to achieve excellent mechanical properties in iron-based medium-entropy alloys.

Reflecting this need, the joint research team proposed the possibility of designing high-strength, high-elongation medium-entropy alloys using spinodal strengthening instead of conventional precipitation strengthening. Spinodal decomposition is a phenomenon where a solid solution spontaneously separates into two different phases within a thermodynamically unstable region at certain temperatures and compositions.

First, the joint research team predicted the composition and temperature conditions where not only precipitates but also spinodal decomposition occur through thermodynamic equilibrium phase diagram calculations and experiments.

Through experiments, they confirmed that nano-scale compositional separation due to spinodal decomposition appeared uniformly throughout the matrix by low-temperature heat treatment without the complex processes required to form precipitates.

In this process, the specimens undergoing spinodal decomposition exhibited a medium-entropy alloy with a 187% improved yield strength (1.1 GPa) and high ductility (28.5%) compared to specimens without spinodal decomposition, the joint research team introduced.

Professor Kim Hyung-seop said, "This study is significant in that it confirmed the mechanical properties of spinodal structures in complex composition alloys," and added, "High-strength, high-elongation alloys are expected to be widely applied in aerospace, automotive, energy, and electronics industries, contributing to product lightweighting and durability improvement."

Meanwhile, this research was conducted with support from the Nano Materials Technology Development Project promoted by the Ministry of Science and ICT and the National Research Foundation of Korea. The research results were published in the July 9 issue of the international academic journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)