Expectations for Improving Quality of Sogyeolgwang

Doosan Enerbility is expanding its digital business capabilities accumulated in the domestic and international power generation sectors to the steel industry.

Doosan Enerbility announced on the 8th that it has signed a "Data Analysis Service Contract for AI Application in the Sintering Process" with the Pohang Institute of Industrial Science and Technology (hereinafter RIST), a research institute specializing in steel and environmental energy technologies. RIST is a research institute fully funded by POSCO and plays a central role in driving POSCO Group's core businesses.

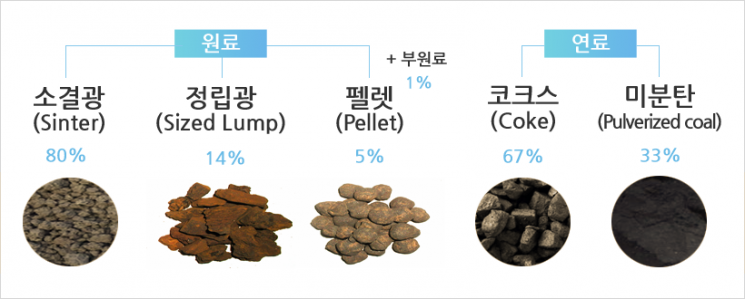

Under this contract, Doosan Enerbility plans to analyze the applicability of AI operation based on sintering equipment data within the POSCO steelworks in collaboration with RIST by December. Sintering is a technology that bonds particles into a single mass by applying heat and pressure to solid powders.

At the steelworks, iron ore is homogenized and processed into a size suitable for the blast furnace before molten iron is produced, forming sintered ore. Yongjin Song, Head of Strategy and Innovation Division at Doosan Enerbility, said, "This can improve energy efficiency used in sintering equipment and enhance the quality of sintered ore."

Since 2013, Doosan Enerbility has operated a "Digital Innovation" organization composed of teams such as Data Analysis and Digital Solutions. It supplies AI-based optimization solutions to domestic 1000MW-class power plants, connecting to control networks to contribute to improved customer reliability and efficiency. The company is expanding various digital businesses, including the predictive diagnosis solution "Prevision" and an automatic defect reading solution for nondestructive testing.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.