Targeting ASEAN with High Electric Vehicle Growth Potential

Breaking Free from China's Dependence on Key Battery Components

"Hyundai Motor Group and Indonesia will create the future together with the spirit of ‘Membuka Jalan Baru (Pioneering a New Path).”

Hyundai Motor Group Chairman Chung Euisun is giving a greeting speech at the inauguration ceremony of Indonesia HLI Green Power on the 3rd.

Hyundai Motor Group Chairman Chung Euisun is giving a greeting speech at the inauguration ceremony of Indonesia HLI Green Power on the 3rd. [Photo by Hyundai Motor Group]

On the 3rd (local time), Chung Euisun, Chairman of Hyundai Motor Group, repeatedly emphasized the importance of the electric vehicle ecosystem at a commemorative event held at HLI Green Power in the Karawang New Industrial Complex, Indonesia. Despite the electric vehicle chasm (temporary demand slowdown) that has contracted the entire industry including batteries, he stressed that electrification is the path forward and urged Hyundai Motor and Indonesia to cooperate to open the future.

The Indonesian government is also promoting the internalization of the entire electric vehicle industry including batteries, aligning interests with Hyundai Motor Group, which regards the ASEAN region including Indonesia as a promising future market. The establishment of an integrated production system for battery cells and electric vehicles this time symbolizes laying a core foundation in the process of creating an ASEAN electric vehicle ecosystem beyond the local market.

A view of 'HLI Green Power,' the battery cell joint production corporation of Hyundai Motor Group and LG Energy Solution located in the Karawang New Industrial Complex, Indonesia

A view of 'HLI Green Power,' the battery cell joint production corporation of Hyundai Motor Group and LG Energy Solution located in the Karawang New Industrial Complex, Indonesia [Photo by HLI Green Power]

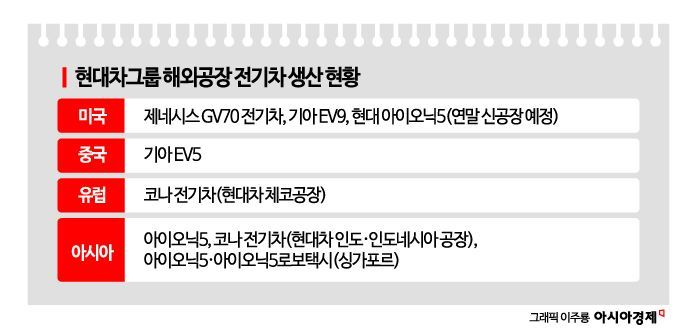

Hyundai Motor Group has so far built its electric vehicle ecosystem centered in Korea. Most derivative electric vehicles, including dedicated electric vehicles such as the Ioniq (Hyundai) and EV (Kia) series, have been manufactured in Korea and exported worldwide. Although some electric vehicles are produced at overseas plants in the U.S., China, India, and the Czech Republic, parts supply such as batteries has been resolved in Korea and other regions.

In Indonesia, through HLI Green Power, a joint venture with LG Energy Solution, raw materials for batteries are procured locally and final complete vehicles are produced. The goal is to expand local charging systems and establish an ecosystem that integrates the entire front and rear industries of electric vehicles, including battery recycling. While the ASEAN market including Indonesia is still slower in electrification compared to China, the U.S., and Europe, Hyundai Motor Group sees great long-term growth potential and is positioning itself to take the lead in the market ahead of others.

The HLI Green Power facility, where the event was held, began construction in September 2021 and started trial production in the second half of last year. Battery cells have been produced since the second quarter of this year. The facility covers 320,000 square meters and includes electrode, assembly, and activation plants. It has an annual production capacity of 10 GWh, enough to supply batteries for more than 150,000 electric vehicles. The batteries here are high-performance NCMA lithium-ion batteries with high nickel, cobalt, and manganese content, enhanced output, and aluminum added to reduce chemical instability.

Ahead of the full-scale launch in the Indonesian market, the new Kona Electric is being pilot-produced at Hyundai Motor Indonesia (HMMI), the local factory [Photo by Hyundai Motor Group].

Ahead of the full-scale launch in the Indonesian market, the new Kona Electric is being pilot-produced at Hyundai Motor Indonesia (HMMI), the local factory [Photo by Hyundai Motor Group].

The batteries will be used not only in the Indonesian plant but also in other Hyundai and Kia models. They will be installed in the new Kona electric vehicle, which will begin mass production on the 17th. The Kona electric vehicle is the second electric vehicle produced at this plant following the Ioniq 5. As demand for advanced-featured sport utility vehicles (SUVs) is increasing locally, the company has a strategy to develop it as a representative local electric vehicle.

The local government is also supporting this effort. Indonesia aims for carbon neutrality by 2060 and targets producing 600,000 electric vehicles by 2030. Electric vehicles are exempt from the two-day driving restriction system and receive up to a 15% exemption or reduction in registration tax in major cities such as Jakarta. If local parts and labor meet localization requirements, luxury tax (15%) is exempted and a temporary value-added tax of only 1% is applied. It has been decided to replace more than 10,000 government vehicles annually with electric vehicles until 2030.

As of last year, Indonesia’s total electric vehicle sales were about 10,800 units, accounting for just over 2% of total new car demand, which is why the growth potential is viewed highly. Chinese electric vehicle companies have also recently entered the local market one after another, intensifying competition. Hyundai Motor plans to launch various models suited to the local market and improve after-sales service satisfaction by preparing specialized electric vehicle maintenance personnel, facilities, and spaces.

Chairman Chung Euisun said, "The activation of Indonesia’s electric vehicle industry will provide new economic opportunities throughout Southeast Asia," adding, "We will strengthen cooperation and pioneer new areas from resource-circulating hydrogen solutions to future aerial mobility.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.