130 Manufacturers in Connecticut

Hanwha Aerospace Also Moves In

Building Material, Parts, and Engine Value Chain

Produces 25% of US Aircraft Engine Parts

Technical Hiring from Nearby Universities and High Schools

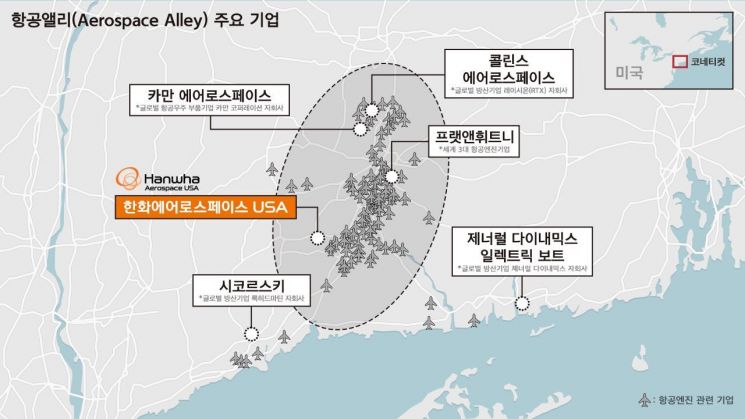

Hanwha Aerospace's U.S. subsidiary (HAU) is located in Connecticut, where over 130 aircraft engine manufacturers are concentrated along Route 91. This area is known as the 'Aerospace Alley.' Just as Silicon Valley in California is synonymous with the IT industry due to the concentration of big tech companies, Connecticut is recognized as the hub of aircraft engine manufacturing. Twenty-five percent of all aircraft engines and parts in the U.S. are produced in Connecticut.

Aircraft engines constitute a major pillar of Connecticut's economy. According to the Connecticut state government, the defense and aerospace industries account for about 10% of Connecticut's Gross Domestic Product (GDP). As of 2022, the aircraft engine manufacturing industry in Connecticut generated an annual GDP of $6.6 billion (approximately 9.1 trillion KRW) and created about 15,500 jobs. These companies paid $2 billion (approximately 2.8 trillion KRW) in local taxes and $6 billion (approximately 8 trillion KRW) in federal taxes as of 2021.

On the 25th of last month (local time), attendees at the 'Future Engine Day' held to analyze the success case of Connecticut's aviation alley in celebration of the 5th anniversary of Korea Aerospace America's establishment (HAU) are taking a commemorative photo. From the left, Paul LaBoy, Chief Manufacturing Officer (CMO) of the Connecticut state government, Jessica Taylor, representative of the Aircraft Parts Association, Liz Linehan, Connecticut State Representative, Luz Yamaya, professor at Central Connecticut State University, and David Broderick, professor at Central Connecticut State University.

On the 25th of last month (local time), attendees at the 'Future Engine Day' held to analyze the success case of Connecticut's aviation alley in celebration of the 5th anniversary of Korea Aerospace America's establishment (HAU) are taking a commemorative photo. From the left, Paul LaBoy, Chief Manufacturing Officer (CMO) of the Connecticut state government, Jessica Taylor, representative of the Aircraft Parts Association, Liz Linehan, Connecticut State Representative, Luz Yamaya, professor at Central Connecticut State University, and David Broderick, professor at Central Connecticut State University. [Photo by Hanwha Aerospace]

Connecticut's Aerospace Alley holds significant implications for us as well. Our government and local authorities are developing a national aerospace industrial complex in Sacheon City and nearby Jinju City in Gyeongnam Province, where the Korea Aerospace Research Institute is located, aiming for completion within this year. Gyeongsangnam-do is investing 1.1267 trillion KRW to establish the Aerospace Parts Technology Institute and plans to support 160 billion KRW for the localization of aircraft engines. They also plan to attract global R&D centers such as Boeing and Airbus. Hanwha Aerospace's domestic operations are also based in Changwon, Gyeongnam. To successfully establish a 'Korean version of Aerospace Alley,' it is necessary to accept the benefits that companies desire.

The top-tier companies in the value chain capable of designing and manufacturing aircraft engines are only the U.S. Pratt & Whitney (P&W), General Electric (GE), and the British Rolls-Royce, collectively known as the 'Big 3.' Hanwha Aerospace is currently challenging these companies and developing advanced aircraft engines. Like semiconductors, aircraft engines are considered a future national growth engine.

The reason to develop aircraft engines is that once they enter a growth trajectory, stable growth is possible. Aircraft engines are at the very upstream of the aerospace industry value chain. They require decades of accumulated technology, a supply of highly skilled labor to sustain it, and massive capital investment. The engine industry has development and usage periods exceeding 10 years, leading to mostly long-term contracts. It experiences less fluctuation due to short-term economic cycles and generates periodic cash flow through MRO (Maintenance, Repair, and Overhaul) businesses, which is regarded as economically stable.

Connecticut has grown for 100 years by building a 'materials-parts-engine' value chain centered around P&W. However, it could not avoid the decline of U.S. manufacturing in the 1990s and the backlash from the 2008 financial crisis. In response, the Connecticut state government actively introduced measures to revitalize manufacturing and attracted large corporations through various tax incentives.

In 2014, the Connecticut state government enacted the Aerospace Reinvestment Act, providing substantial tax credits to major aerospace companies reinvesting over $100 million (approximately 130 billion KRW) within Connecticut. After the law passed, P&W announced an investment of $500 million in aerospace research facilities following about two years of negotiations with the state government.

At the 'Future Engine Day' held on the 25th of last month (local time) to analyze the success of Connecticut's Aerospace Alley on the occasion of HAU's 5th anniversary, Paul Laibow, Connecticut's Chief Manufacturing Officer (CMO), said, "Connecticut operates nine funds supporting manufacturing, and small companies with fewer than 100 employees can receive up to $250,000 (approximately 350 million KRW) in grants."

Additionally, companies employing 20 or more people and maintaining that for two years can receive a payroll tax refund of up to 50% for three to eight years. There is also a 6.35% tax reduction on facility investments. Hanwha Aerospace has also benefited from these incentives.

Connecticut is also proactive in talent development. It strengthens the talent pool by nurturing engineering talent and designs curricula at universities to develop skills needed by companies, thereby attracting customized excellent talent in the future. Hanwha Aerospace has partnered with nearby regional universities and invests with a long-term perspective in talent development. At the end of last year, it invested $200,000 to establish a mechanical engineering and engineering design lab at Central Connecticut State University. So far, it has hired over 100 technical personnel as new employees from universities and technical high schools near Connecticut.

Connecticut State Representative Liz Linehan said, "What differentiates Hanwha from other companies is that it provides health insurance during internships," adding, "In the U.S., where health insurance is not universal, this is a tremendous benefit." HAU recruited 10 college interns this summer, and most are expected to be hired as full-time employees after their internships.

Connecticut believes that building infrastructure to create jobs is essential for attracting companies. Representative Linehan said, "Since COVID-19, what employees want most is a healthy and happy community," adding, "Investing in communities by creating more housing, convenient transportation, and childcare incentives is fundamentally linked to business growth."

On the 26th of last month (local time), at a meeting hosted by Hanwha Aerospace's U.S. branch (HAU) inviting former P&W engineers, Professor Vito Moreno of Connecticut State University (left) and Om Sharma, Senior Researcher at United Technologies Research Center, are answering questions from the press.

On the 26th of last month (local time), at a meeting hosted by Hanwha Aerospace's U.S. branch (HAU) inviting former P&W engineers, Professor Vito Moreno of Connecticut State University (left) and Om Sharma, Senior Researcher at United Technologies Research Center, are answering questions from the press. [Photo by Hanwha Aerospace]

At a meeting hosted by HAU on the 26th of last month, Professor Vito Moreno of the University of Connecticut, a former P&W employee, was asked whether he sees a possibility for Korea to enter the aircraft engine market. He replied, "In the past, loyalty between aircraft manufacturers and engine manufacturers was high, but now economics drives the market," adding, "The reason the advanced geared turbofan engine was a great success at P&W is that it significantly reduces operating costs in terms of efficiency."

He continued, "From an infrastructure perspective, you need to be able to employ thousands of engineering personnel," and "Because you need to manufacture parts, assemble engines, and conduct testing, large-scale facility investment is also necessary. With substantial time and money invested under Korean government support, I think it is technically feasible."

Another former P&W employee, Om Sharma, senior researcher at United Technologies Research Center, said, "Based on my experience over the past 40 years, the cost and time required for engine development are two to three times higher than expected," adding, "You should not cut the engine budget. Patience is necessary." He also emphasized, "Collaboration with universities, industry, and external partners is important," and "It is essential to establish technical advisory committees at both government and industry levels."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.