Goldman Sachs "1 Million Humanoid Shipments by 2031"

Humanoid Price Decline and Technological Advances Progressing Together

Tesla Mentions Optimus Deployment in Production Process by Year-End

Chinese EV Companies Already Actively Using Robots in Factories

Auto Industry "Humanoids' Final Goal Is Deployment in Assembly Processes"

Hyundai Motor Group's increase in its stake in Boston Dynamics is seen as a clear example of global automakers' growing interest in robotics. Tesla has already embarked on in-house development, while Chinese companies are promoting the introduction of humanoid robots into electric vehicle production lines through partnerships with domestic robotics firms. The industrial convergence between automobiles and robotics can broadly expand not only cost reduction in manufacturing but also mobility service areas such as logistics and delivery.

Humanoid robot WalkerS by Ubittech deployed on the production line of Chinese electric vehicle company NIO

Humanoid robot WalkerS by Ubittech deployed on the production line of Chinese electric vehicle company NIO [Photo by Ubittech website]

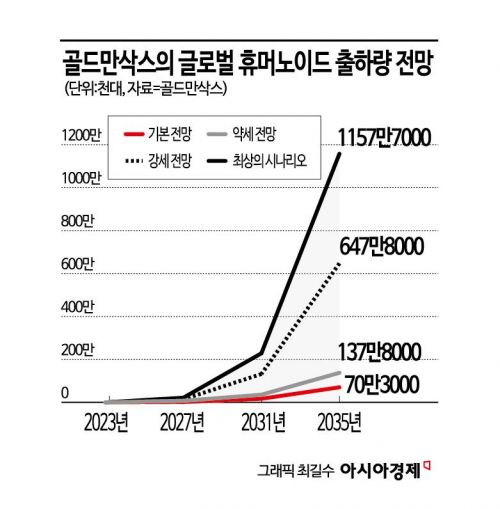

Global investment bank Goldman Sachs recently projected in a report that the global humanoid robot market size will reach $38 billion (approximately 52 trillion KRW) by 2035. Goldman Sachs had previously forecasted the market size to be $6 billion (about 8 trillion KRW) but significantly revised the figure upward within a year. At the same time, it predicted that humanoid robot shipments will reach 1 million units by 2031.

The upward revision is due to the rapid decline in robot production costs and the introduction of AI technology, which has accelerated the technological advancement of leading companies beyond expectations. Goldman Sachs analyzed that the price of humanoid robots dropped by more than 40%, from $250,000 per unit in 2022 to $150,000 in 2023. Accordingly, it expects the introduction of versatile humanoid robots in actual factories to be possible as early as this year. It also anticipates that the time when consumers can directly purchase humanoid robots will be accelerated by 2 to 4 years, occurring between 2028 and 2031.

Automakers Accelerate Humanoid Robot Adoption

Among automakers, Tesla was the first to declare the humanoid robot war. In 2021, Tesla first announced it was preparing a robot project. Tesla attracted attention by aggressively setting development speed and mass production target prices. The company unveiled the first-generation model 1 year and 7 months after announcing the project. The first-generation Optimus could mimic human actions and use its fingers to move simple objects. The second-generation Optimus, revealed about 9 months later, featured much smoother and more natural movements. It could maintain balance while performing yoga and squat motions, and carry out delicate tasks such as moving eggs with its fingers or folding thin T-shirts. Elon Musk announced plans for mass production at a price range of $20,000 to $25,000 per unit. He also mentioned that the robot could be deployed in electric vehicle production lines as early as the end of this year.

Boston Dynamics, acquired by Hyundai Motor Group, is regarded as the company with the most advanced hardware technology. Recently, the company unveiled a new humanoid robot product utilizing a new electric drive method. Until now, the bipedal robot Atlas has used a hydraulic drive system. While hydraulic actuators provide strong force, they have drawbacks such as heavy weight and loud noise. The new Atlas equipped with electric actuators is not only lighter but also has reduced production costs. Boston Dynamics aims to secure competitiveness by lowering costs while maintaining Atlas's hardware technology.

Chinese automakers, familiar with automated production processes, are actively promoting robot adoption in electric vehicle manufacturing. Rather than developing in-house, they have started robot introduction through partnerships with domestic robotics companies, beginning with simple tasks. Chinese robotics firm Ubtech Robotics supplies the humanoid robot 'Walker S' to major Chinese electric vehicle manufacturers. It was first deployed at NIO's Hefei factory and recently signed an agreement to supply humanoid robots to Dongfeng Motor. Walker S, which is about 170 cm tall?similar to human height?can perform simple tasks such as seatbelt inspection, door lock testing, body quality inspection, and label attachment.

"Robots Must Be Introduced in Assembly Processes"

Industry insiders agree that true automation of automobile production requires the introduction of robots in the 'assembly process.' The automobile production process consists of five main stages: press, body assembly (welding), painting, assembly, and inspection. Most of the processes involving cutting, welding, assembling, and painting heavy car bodies are already automated. However, the assembly process, which involves assembling seats and various interior parts and wiring electrical components, is still done manually.

Even Tesla's Shanghai factory, which boasts an automation rate of 95%, reportedly requires significant labor input in the assembly line. Assembly is highly complex because parts are made of different materials such as plastic, rubber, and wood, and electrical wiring varies by options. To automate this process, it is essential to deploy humanoid robots capable of high intelligence and precise hand movements similar to humans. Lee Sang-soo, a researcher at Hi Investment & Securities, said, "Because the assembly process involves many variations depending on specifications, most companies experience production bottlenecks in this stage. It is difficult to convert this process into existing industrial robot algorithms, so deploying high-spec humanoid robots in this process can be considered."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)