Kigyeon Opens Path for Fine Dust Measurement in Harsh Environments

A path has been opened to lead the measurement of fine dust in harsh conditions, which previously relied heavily on overseas technology, using domestic independent technology. A pretreatment technology capable of real-time monitoring of fine dust (PM10) and ultrafine dust (PM2.5) emitted from thermal power plants, incinerators, and other sources has been developed for the first time in Korea. It is expected to be widely used not only in newly constructed sites but also in existing sites for monitoring fine dust emissions.

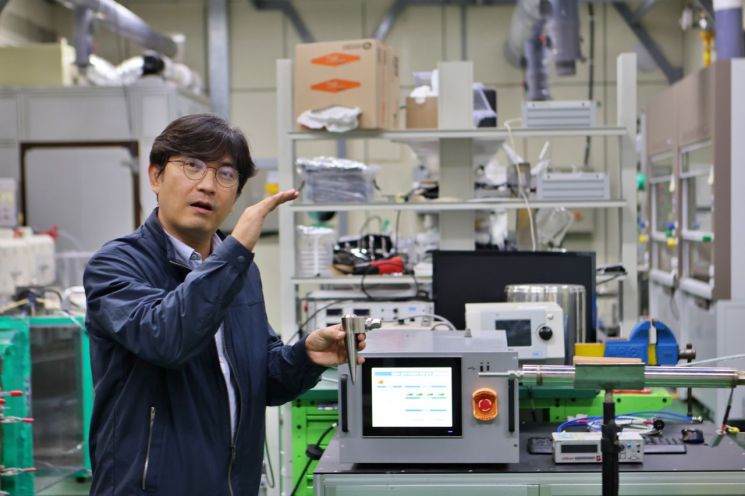

The AI ??assistant that manages Korean data in the CMS translates it into English.

The AI ??assistant that manages Korean data in the CMS translates it into English.Photo by Gigaeyeon

The Korea Institute of Machinery and Materials (Director Ryu Seok-hyun) announced on the 14th that the research team led by Han Bang-woo, head of the Urban Environment Research Laboratory, has developed a technology for the first time in Korea that converts the high-temperature, high-concentration environment inside chimneys to ambient temperature and low-concentration atmospheric conditions, enabling real-time measurement of fine dust (PM10) and ultrafine dust (PM2.5) by size.

The research team utilized four independently developed core technologies: ▲variable flow rate and pressure-compensated isokinetic sampling technology, ▲quantitative sampling dilution technology, ▲droplet separation technology, and ▲wall loss suppression technology, enabling management of fine dust (PM10) and ultrafine dust (PM2.5) emitted from chimneys by particle size rather than total suspended particles (TSP). This real-time fine dust monitoring technology has been performance-verified through a six-month long-term demonstration at domestic thermal power plants and incinerators.

Previously, it was difficult to obtain accurate real-time fine dust measurement data due to harsh environmental conditions inside chimneys such as high temperature and high concentration. The current measurement method, optical transmission measurement, indirectly measures the amount of light reduced after passing light through all dust particles generated in the chimney, making accurate monitoring of fine dust challenging.

Additionally, the existing gravimetric measurement method involves sampling fine dust over a certain period and measuring the weight on a filter, which takes a long time to obtain concentration data, limiting real-time management.

The research team reduced measurement errors caused by changes in chimney flow velocity by slowing down the velocity of exhaust gas entering the measuring device through isokinetic sampling technology. This is why accurate measurement of fine dust is possible.

The team also enabled automatic control of air injection volume to extract a constant amount of exhaust gas despite various environmental changes such as pressure and temperature inside the chimney, and minimized droplet formation caused by condensation by maintaining a constant high temperature. Air was injected into a tube with many holes to minimize wall adhesion of fine dust.

Han Bang-woo, head of the Urban Environment Research Laboratory at the Korea Institute of Machinery and Materials, said, “This is the first technology that can obtain accurate concentration and size distribution information of fine dust emitted from industrial chimneys in real time,” adding, “We will strive to establish an emission source management system based on the measured fine dust emission data.”

This research was conducted with support from the Ministry of Environment’s project “Demonstration of Continuous Fine Dust Measurement Technology for Fixed Pollution Source Emission Facilities Using Multi-Stage Dilution Sampling Technology.” This technology was selected as one of the ‘Top 20 Excellent Environmental R&D Achievements of 2023’ by the Ministry of Environment.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.