AI-Based Waste Sorting Robot 'Aitron'

Deployed and Utilized in Namdong-gu, Incheon

"No More Inconvenience in Waste Separation"

From households to recycling sorting centers where various wastes are gathered, waste separation is done by human hands. However, when done manually, recyclable materials are sometimes missed and such resources are discarded as is. There are other problems with recycling work handled by humans. Recycling sorting centers are environments prone to exposure to foul odors, dust, and hazards, making it difficult to find workers. EightTech is a company that has stepped up to solve these issues. They do so through the automated waste sorting robot 'Aitron.'

Park Tae-hyung, CEO of EightTech, is introducing the waste sorting robot 'Aitron' at the headquarters located in Guro-gu, Seoul, on the 28th.

Park Tae-hyung, CEO of EightTech, is introducing the waste sorting robot 'Aitron' at the headquarters located in Guro-gu, Seoul, on the 28th. [Photo by Innobiz Association]

On the 28th, Park Tae-hyung, CEO of EightTech, said, "I hope people no longer have to directly face problems related to waste," adding, "I established EightTech to solve the problems of existing recycling resource sorting centers and to realize urban mining." Urban mining refers to the industry of extracting resources from products that have already reached the end of their life and from waste.

Park, who founded EightTech in 2020, focused on developing AI-based waste sorting robots and introduced the first Aitron unit in 2022. Aitron has learned from over 2.6 million pieces of household waste data, achieving a recognition accuracy rate of 99%. It can sort seven types of waste and further classify a total of 45 types based on color and material.

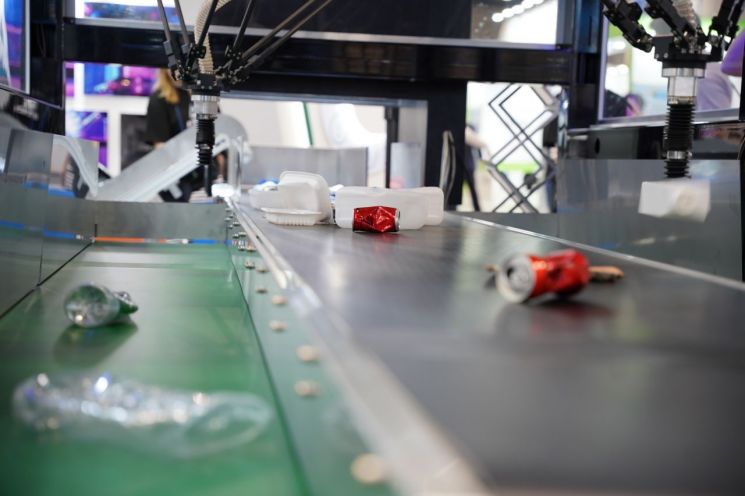

At EightTech’s headquarters in Guro-gu, Seoul, observing how Aitron operates, it first uses a blower (air blower) vacuum method to suction and pick up waste. It separated plastics, glass, cans, and other materials into different groups. The speed was faster than human sorting, and the accuracy was not inferior. While one person can sort about 40 pieces of waste per minute, Aitron can sort 96 pieces, achieving 2.4 times the sorting speed. Lee Do-kyung, EightTech’s Chief Technology Officer (CTO), said, "Aitron can operate 24 hours a day, increasing waste sorting speed by 140% and reducing sorting costs by 266%."

In South Korea, there are about 450 recycling sorting centers including public and private facilities, but most are in very poor condition and only about 30% of the daily incoming waste is processed. Accordingly, EightTech is conducting private investment proposal projects focusing on local governments with severely aged facilities and low sorting rates.

Currently, Aitron is deployed and utilized in Namdong-gu, Incheon; Namyangju-si, Gyeonggi-do; and Cheongdo-gun, Gyeongsangbuk-do. This year, the first 'Dual Aitron' unit, equipped with robotic arms on both front and back, will be installed in Songpa-gu, Seoul, and a Seoul city testbed demonstration project will be conducted. Exports to overseas markets are also underway. The first phase of overseas market research has been completed, and negotiations are ongoing with Singapore, Indonesia, and Australia.

Song Han-cheol, Executive Director of EightTech, said, "EightTech is the only company that has sold sorting robots domestically, so although only 12 units have been sold so far, our market share is 100%. Based on our unique technology that produces most of the system in-house, we expect to sell more than 40 units this year."

EightTech plans to unveil a smart factory, a robotic resource recovery center, in the second half of this year. The smart factory will completely replace existing manual sorting work with Aitron. From the preprocessing stage of removing labels attached to PET bottles or plastics to sorting work through the installation of more than 20 Aitron units and a circular conveyor, the system will operate unmanned 24 hours a day. CTO Lee Do-kyung said, "Through the smart factory, we expect to improve the existing recycling rate from 30% to 80%," adding, "We are currently preparing a factory of about 500 pyeong in Seo-gu, Incheon."

Recently, EightTech signed an agreement with SK Eco Plant to develop a recycling waste sorting system for apartment complexes. The plan is to establish an automatic household waste separation station and provide sorting solutions from the disposal stage. CEO Park said, "We are considering ways for people to protect the environment easily without inconvenience in separating waste," adding, "We will strive to lead ESG (Environmental, Social, and Governance) through waste sorting robots and plant operations."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)