A high-efficiency membrane manufacturing technology that can selectively permeate carbon dioxide from gas mixtures by tuning polymer structures has been developed domestically. This technology is expected to be widely applicable in the chemical industry and environmental fields, potentially aiding in the realization of carbon neutrality in the future.

KAIST announced on the 22nd that Professor Bae Taehyun's research team from the Department of Bio and Chemical Engineering developed a technology that controls the structure and chemical properties of polymer membranes to separate and remove carbon dioxide with high efficiency.

Professor Bae Taehyun of the Department of Bio and Chemical Engineering (right) and Hongju Lee, PhD candidate of the Department of Bio and Chemical Engineering (left). Provided by KAIST

Professor Bae Taehyun of the Department of Bio and Chemical Engineering (right) and Hongju Lee, PhD candidate of the Department of Bio and Chemical Engineering (left). Provided by KAIST

Membranes are thin films that selectively allow target substances to permeate and have attracted attention as low-energy separation technologies. However, conventional polymer membranes have limitations due to their dense structures, leading to research efforts to enhance gas permeation selectivity by using materials with certain micropores as membranes.

Nevertheless, most studies on molecular sieve membranes faced difficulties in practical applications due to challenges in mass production, complex manufacturing processes, and low mechanical strength.

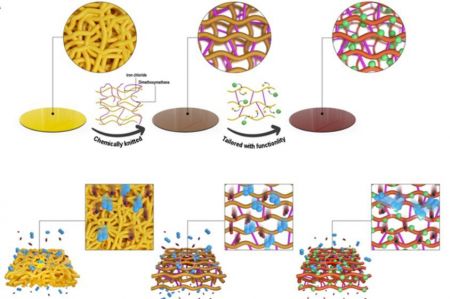

In contrast, the research team succeeded in implementing a molecular sieve membrane capable of mass production (low cost) by using a highly processable polymer material and forming micropores through relatively controllable chemical reactions.

The newly developed membrane is characterized by mechanical and chemical stability and flexibility comparable to polymer membranes, unlike carbon molecular sieve membranes that are high-performance but brittle. Above all, it applies a process favorable for mass production, providing advantageous conditions for commercialization.

It is also noteworthy that the membrane exhibits carbon dioxide separation performance comparable to the best-performing carbon molecular sieve membranes developed to date.

The newly developed technology can be custom-tuned according to separation processes, making it a versatile technology applicable across various industrial fields. The research team expects this technology to be applied and utilized broadly in chemical industries such as petrochemical, pharmaceutical, eco-friendly renewable energy businesses, and environmental fields including carbon neutrality.

Schematic diagram of the evolution of molecular membranes into polymer membranes tuned with chemical functional groups. Provided by KAIST

Schematic diagram of the evolution of molecular membranes into polymer membranes tuned with chemical functional groups. Provided by KAIST

This research involved Ph.D. candidate Lee Hongju from the Department of Bio and Chemical Engineering at KAIST as the first author. The research results were also introduced in the international journal Science Advances (online edition, April 12).

Researcher Lee Hongju stated, "The newly developed carbon dioxide membrane is significant in that it leads to a revolutionary paradigm shift in the concept of molecular sieve membranes and enables securing carbon dioxide separation performance through a relatively simple process."

Meanwhile, this research was conducted with support from the Korea Research Foundation's mid-career researcher support program, the Distributed Low-Carbon Hydrogen Production project of the Leading Research Center, and the Saudi Aramco-KAIST CO2 Management Center.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.