Israel ExtraLith, an affiliate responsible for the lithium business technology of Georit Energy, demonstrated a 95% recovery rate through a lithium direct extraction (DLE) technology demonstration.

On the afternoon of the 13th, Georit Energy held a DLE technology demonstration event for investors and stakeholders at its research center located in Anyang Mega Valley, Gyeonggi Province. It was explained that by using the adsorbent applied with this technology, lithium can be extracted from a wide range of brine lakes with ultra-low to high concentrations.

This technology demonstration was directly presented in Korea by the technical team of Israel ExtraLith, in which Georit Energy holds a 29.88% stake as the single largest shareholder.

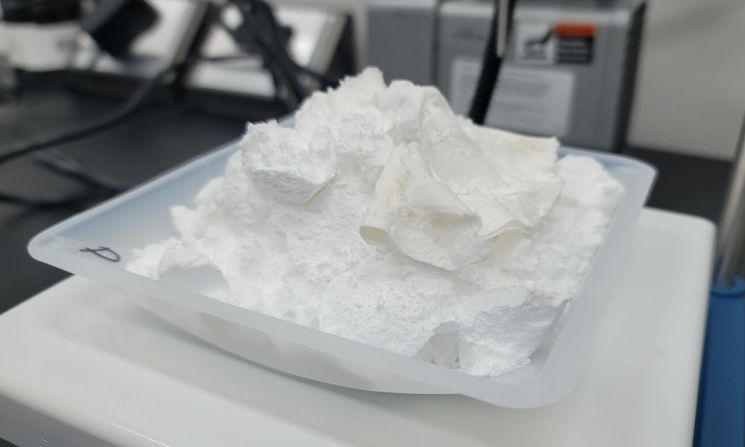

The adsorbent developed by ExtraLith extracts lithium quickly at low salinity through an ion exchange method. A related U.S. patent application for this adsorbent has also been filed.

A company representative stated, "We are developing ion exchange method DLE (lithium direct extraction) technology and conducting lithium extraction business. Our technology has been highly recognized overseas, and efforts are underway to commercialize direct lithium extraction from various brine lakes."

The representative added, "As the first domestic company to demonstrate and verify DLE technology, we were able to directly observe a 95% lithium recovery rate. This is meaningful as it raised expectations for the commercialization of DLE technology."

During the demonstration, lithium wastewater secured from a major domestic lithium secondary battery material manufacturer was used as the raw material. Georit Energy plans to share the demonstration results with lithium secondary battery material manufacturers and accelerate discussions regarding the installation and operation of pilot plants.

Considering the limited availability of natural brine, geothermal water, and oilfield brine in Korea, Georit Energy is targeting the lithium wastewater market. The company stated that it is extracting lithium from lithium wastewater discharged and discarded during the secondary battery cathode material manufacturing process.

For secondary battery material manufacturers, the company plans to actively promote and provide ▲ environmentally friendly wastewater treatment and lithium recovery technology for lithium-containing wastewater ▲ lithium recovery process technology that minimizes the use of harmful substances and greenhouse gas emissions ▲ eco-friendly recovery technology for impurities generated during the lithium recovery process ▲ battery-grade high-purity lithium compound manufacturing process technology.

The representative said, "It is of great value that we have created a new supply source through lithium wastewater and transformed it into a high value-added product. From the perspective of secondary battery material manufacturers, it offers the advantage of maximizing production efficiency by recovering losses in input materials and increasing production yield."

He emphasized, "Once commercialized, it will create economic value by enabling the production of thousands of tons of LCE (lithium carbonate equivalent) from lithium wastewater discharged domestically."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.