Opening of the Largest Battery Exhibition 'InterBattery' on the 6th

LG Energy Solution 'Reducing Manufacturing Costs through CTP'

SK On 'LFP with High Cold Resistance and Density'

Samsung SDI 'Dream Battery Solid-State Roadmap'

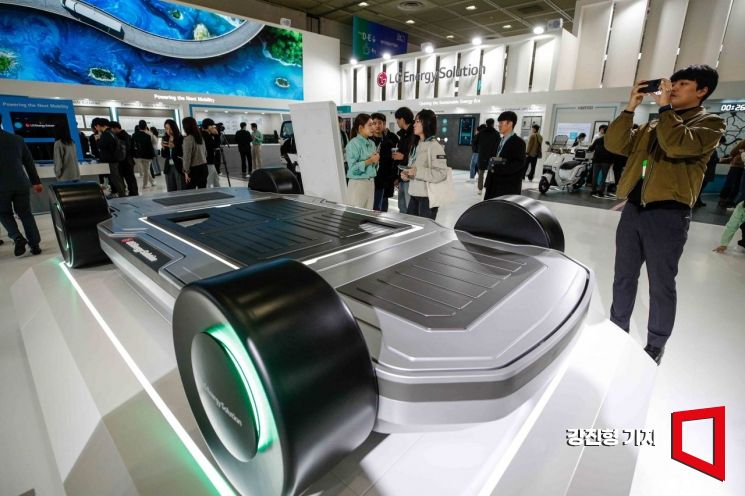

On the 6th, visitors are viewing LG Energy Solution's electric vehicle batteries at 'InterBattery 2024' held at COEX in Gangnam-gu, Seoul. Photo by Jin-Hyung Kang aymsdream@

On the 6th, visitors are viewing LG Energy Solution's electric vehicle batteries at 'InterBattery 2024' held at COEX in Gangnam-gu, Seoul. Photo by Jin-Hyung Kang aymsdream@

Is it about breakthrough technology or competition in price and efficiency? The battery industry, caught in a downturn, presented very different "hurdle-crossing solutions" at Korea's largest battery exhibition.

On the 6th, 'InterBattery 2024,' established as a global battery exhibition, opened at COEX in Gangnam-gu, Seoul. Marking its 12th edition this year, InterBattery featured a total of 579 companies, including major domestic battery cell manufacturers and firms related to materials, equipment, and components.

The issue is price and efficiency... LG Energy Solution unveils CTP, SK On presents cold-resistant LFP

LG Energy Solution, the No. 1 domestic battery cell company, unveiled pouch-type CTP (Cell-to-Pack) technology for the first time. Through a mockup of an electric vehicle's underside, they showcased CTP technology that eliminates the module stage. Without modules, the pouch-type batteries appeared more densely packed inside the pack. A company representative said, "Our proprietary technology enhances the pack's rigidity to prevent safety incidents like fires while using lightweight pouch cells," adding, "Reducing parts and simplifying processes can lower manufacturing costs and improve price competitiveness."

On the 6th, visitors are viewing SK On's electric vehicle battery at 'InterBattery 2024' held at COEX in Gangnam-gu, Seoul. Photo by Jinhyung Kang aymsdream@

On the 6th, visitors are viewing SK On's electric vehicle battery at 'InterBattery 2024' held at COEX in Gangnam-gu, Seoul. Photo by Jinhyung Kang aymsdream@

On the same day, an Isuzu (ISUZU) ELF electric truck equipped with LG Energy Solution's cylindrical batteries was also exhibited. The ELF electric truck allows users to choose battery capacities of 40 kWh, 60 kWh, or 100 kWh.

SK On also unveiled LFP (Lithium Iron Phosphate) batteries that are resistant to cold. Although LFP batteries are inexpensive, their vulnerability to cold has limited their widespread use in electric vehicles. SK On introduced LFP batteries that overcome this weakness, strengthening their mid-to-low price product lineup. As price competition intensifies, SK On appears to be actively entering the LFP market, which is gaining attention. An SK On representative said, "LFP batteries typically see driving range drop by more than 50% in cold weather, but SK On's LFP batteries increase energy density and improve driving range by over 10% compared to existing models in low temperatures."

Samsung SDI reemphasizes the dream battery

Samsung SDI unveiled a solid-state battery sample on the 6th at InterBattery held at COEX in Gangnam-gu, Seoul. Photo by Choi Seoyoon

Samsung SDI unveiled a solid-state battery sample on the 6th at InterBattery held at COEX in Gangnam-gu, Seoul. Photo by Choi Seoyoon

Samsung SDI revealed the industry's first roadmap to mass-produce all-solid-state batteries by 2027, which use solid electrolytes instead of liquid ones to dramatically improve safety. They plan to mass-produce the industry's highest energy density '900 Wh per liter all-solid-state battery,' which has about 40% higher energy density than conventional prismatic batteries. Samsung SDI possesses unique technology that uses lithium instead of metal for the anode, increasing the cathode space and allowing more cathode material to be packed in, thereby boosting energy density. A Samsung SDI representative said, "All-solid-state batteries offer superior safety and performance compared to conventional prismatic batteries, but they also present many technical hurdles," adding, "Nonetheless, being the first in the industry to disclose a concrete roadmap reflects our confidence in mass-producing all-solid-state batteries."

This year, POSCO Group, which is commencing commercial production of lithium from Argentina's salt lakes and nickel from Indonesia, attracted attention by exhibiting lithium and nickel ores. A POSCO Holdings representative said, "Although battery raw material prices have stabilized, supply issues remain critical," and added, "We hope that lithium and nickel produced this year will contribute to stabilizing our battery supply chain."

Battery materials company EcoPro unveiled a cathode material production process that reduces manufacturing costs by more than 30% by integrating eco-friendly technology. An EcoPro representative said, "Recycling at the cell unit level or higher is technically challenging compared to conventional methods," but added, "We will realize this through our unique manufacturing technology capabilities."

Meanwhile, the Ministry of Trade, Industry and Energy announced on the same day that it will support over 500 billion KRW in domestic battery research and development (R&D) over the next five years. Kang Kyung-sung, 1st Vice Minister of the Ministry of Trade, Industry and Energy, participated in the opening ceremony of 'InterBattery 2024' and said, "In consultation with related ministries, we will provide more than 500 billion KRW in R&D support over the next five years for next-generation battery development such as all-solid-state batteries, development of affordable batteries like LFP and sodium, and eco-friendly technologies including reuse and recycling."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)