Integration of Existing Drive Transmission System Inside Wheel

Power Delivered Directly to Wheel with Independent Motor

Increased Space Utilization by Eliminating Drive Shaft

Battery Installation and Seat Arrangement Become More Flexible

The 2018 Australian film Upgrade features a car that could be seen in the near future. A notable aspect is that the driver can turn around behind the steering wheel. There is a scene where the couple faces each other and talks, and they can also lie down. Like the cars in this sci-fi movie, cars that allow lying down will be available within a few years. Hyundai Motor Company and Kia announced on the 27th that they have developed a system that moves the existing vehicle drive system to the wheels to expand the interior space. As a pioneering technology, it is expected to take several years before actual mass production. The company held the ‘Uniwheel Tech Day’ at the Community House Masil in Jung-gu, Seoul on the 28th and unveiled the Universal Wheel Drive System for the first time in the world.

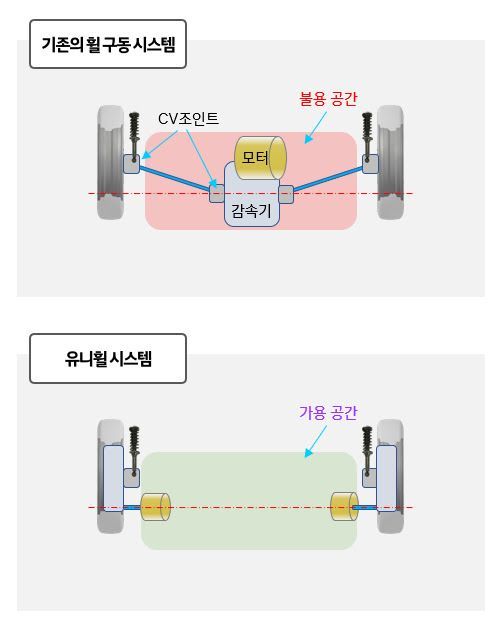

Uniwheel is a function-integrated wheel drive system that moves the main electric vehicle drive components inside the wheel. In internal combustion engine vehicles, the power generated by the engine and transmission is transmitted to the wheels through the drive shaft and CV joints (components that deliver driving force to the wheels). Electric vehicles have replaced the engine and transmission with a motor and reducer, but the drive transmission system remains the same as in internal combustion engine vehicles.

Universal Wheel Drive System Module Developed by Hyundai Motor Company and Kia [Photo by Hyundai Motor Company]

Universal Wheel Drive System Module Developed by Hyundai Motor Company and Kia [Photo by Hyundai Motor Company]

Uniwheel incorporates the drive shaft and reducer functions of electric vehicles entirely inside the wheel. First, a motor is placed next to each wheel, eliminating the need for a separate drive shaft. Uniwheel consists of three types of gears (sun gear, pinion gear, ring gear). When the motor generates power, it is directly transmitted to the wheel through the interlocking gears. This principle enhances the drive efficiency of Uniwheel. Conventional drive systems lose efficiency because power is transmitted to the wheels through the shaft, but Uniwheel’s independent motor delivers power directly to the wheels.

Uniwheel also replaces the reducer function in electric vehicles. The reducer plays a role similar to the transmission in internal combustion engine vehicles. The motor has a higher revolutions per minute (RPM) than an internal combustion engine. In other words, electric vehicles require deceleration to reduce RPM instead of shifting gears to increase speed depending on the situation. Uniwheel has two gears with fewer teeth and one gear with more teeth meshed together, allowing adjustment of the reduction ratio between the input shaft and output shaft.

Comparison of the Universal Wheel Drive System Developed by Hyundai Motor Company and Kia with Existing Vehicle Drive Systems

Comparison of the Universal Wheel Drive System Developed by Hyundai Motor Company and Kia with Existing Vehicle Drive Systems [Photo by Hyundai Motor Company]

The reduction ratio controls the rotational speed transmitted by the gears. It is expressed as the ratio of the size of the input gear to the output gear. If the input gear is larger than the output gear, the reduction ratio is greater than 1, causing the output gear to rotate slower than the input gear. In other words, deceleration occurs. Conversely, if the reduction ratio is less than 1, acceleration occurs. In other words, Uniwheel can create high torque (rotational force) at the wheel by decelerating the rotation generated by the motor without a separate reducer.

By utilizing these characteristics of Uniwheel, interior space that was previously unusable can be better utilized. This is because the drive shaft, reducer, and motor are directly connected to each wheel. With the motor between the left and right wheels removed, more cargo can be loaded in this space. If used as battery installation space, driving range can be extended. Even without increasing the vehicle size, it may be possible to secure a driving range comparable to large electric vehicles. Furthermore, optimizing battery packaging (the process of sealing the battery) could also expand passenger space. Hyundai explains that this technology is expected to be especially useful for PBVs (purpose-built vehicles such as trucks).

Internal gear structure of the universal wheel drive system developed by Hyundai Motor Company and Kia [Photo provided by Hyundai Motor Company]

Internal gear structure of the universal wheel drive system developed by Hyundai Motor Company and Kia [Photo provided by Hyundai Motor Company]

Hyundai Motor Company and Kia plan to continue efforts to enhance product competitiveness by advancing gear ratio adjustment and lubrication cooling systems. They have also filed and registered eight patents related to Uniwheel in major countries including Korea, the United States, and Europe.

Jongsul Park, Senior Research Fellow at Hyundai Motor Company and Kia Advanced Technology Institute, said, “We are pleased to present an innovative idea that can be a game changer in the future mobility market,” adding, “We will do our best to perfect the technology so that customers can experience mobility in a completely new way, unlike anything before.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.