Multi-joint Robot Capable of Performing the Same Tasks as Humans

Introduction of No.1 Coke Oven at Gwangyang Steelworks, Expansion to All Plants

POSCO, prioritizing worker safety as its top value, has taken the lead in realizing a safe steel mill by successfully developing the world's first unmanned sealing technology for coke oven doors required in the steelmaking process.

Since coal cannot be used directly in the steel production process, it is placed in an oven (carbonization chamber) under high temperature and high pressure to remove moisture and harmful substances, transforming it into coke.

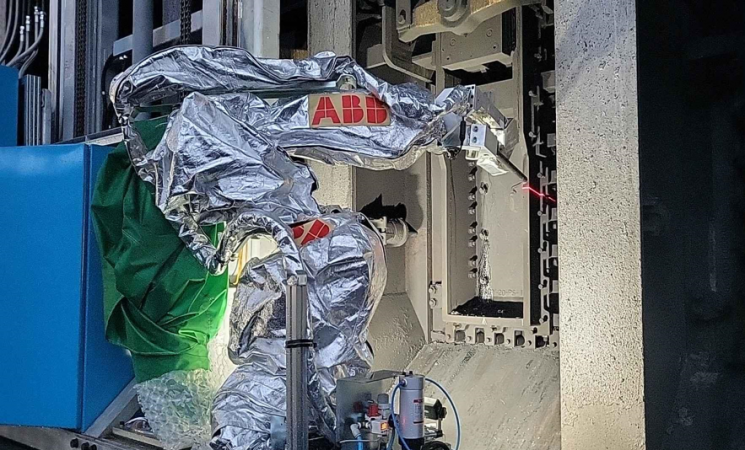

Demonstration of unmanned robot solution technology introduced in No.1 coke oven at Gwangyang Steelworks

Demonstration of unmanned robot solution technology introduced in No.1 coke oven at Gwangyang Steelworks Photo by Gwangyang Steelworks

Because the heat generated at this time can cause deformation of the oven door and adhesion of foreign substances, continuous maintenance is essential.

To eliminate safety risks that may occur during the maintenance process of the oven door and to enhance worker safety, POSCO launched a team led by the Robot Solutions Research Group at POSCO Technical Research Institute in early 2023 and began research and development.

After reviewing the feasibility of robot utilization with the Korea Institute of Robot Convergence, POSCO collaborated with private companies to establish demonstration facilities and control systems. With the support of employees at Hwaseong Plant, they conducted actual application and trial operations, successfully developing the world's first unmanned sealing technology for coke oven doors.

Since a multi-joint robot is used, it has the characteristic of being able to perform tasks just like a human. When the operator issues a command from the control room, the robot moves to the required work location, reads position information, corrects the distance, and proceeds with maintenance work.

In particular, it is even more meaningful because the operator can complete the work by monitoring the robot’s work status through a monitor in the control room without having to move directly, fundamentally eliminating risks that may occur during work.

POSCO plans to lead the realization of a safe workplace by introducing the unmanned sealing operation robot solution technology to the No. 1 coke plant at Gwangyang Steelworks and then expanding the technology to all ovens in coke plants together with Pohang Steelworks.

POSCO President Lee Si-woo said, “Our POSCO prioritizes human safety above all else in our operations,” and added, “This robot solution technology will make a significant contribution to realizing the value of safety.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.