Started Battery Discharge Business Through Affiliate Ecosell

Secured Three Major Future Growth Engines Including EV Reducers and Robot Reducers

DIC, a leading domestic company in the electric vehicle (EV) reducer sector, is making a full-scale entry into the used battery business through its affiliate Ecosell. The company plans to accelerate its performance by leveraging its existing cash cow, EV reducers, and new growth engines such as robot reducers.

According to DIC, Ecosell, a subsidiary specializing in the used battery business, has begun full-scale operation of its battery discharge plant. Ecosell is a joint venture (JV) established last year with 51% investment from Jane Motors, a 100% subsidiary of DIC, and 49% from Solarlight Korea, a company specializing in used batteries.

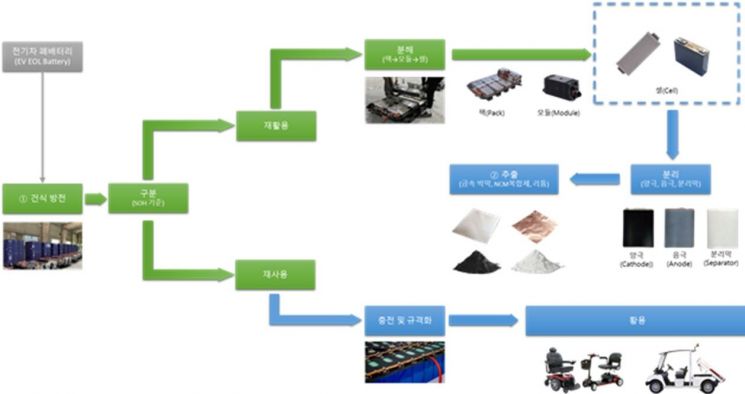

To recycle or extract resources from used batteries, a pre-treatment process of discharging the collected batteries is essential. Ecosell plans to provide pre-treatment solutions such as discharge in the early stages of the business and later develop proprietary resource extraction technology to extract high-purity core materials.

DIC uses its own dry discharge technology instead of the wet (brine) discharge method commonly used by other used battery recycling companies. Dry discharge is a discharge method that removes residual energy using electro-physical techniques, enabling large-capacity discharge. The biggest advantage is that the discharge time is shortened to within 3 hours compared to at least 48 hours for wet discharge, securing speed and cost-effectiveness.

Additionally, dry discharge is considered an eco-friendly process that does not generate environmentally harmful substances. This contrasts with wet discharge, which continuously causes environmental issues due to the large amount of harmful substances such as wastewater it emits. The discharge efficiency also removes 99.9% of the battery's residual charge, allowing safe disassembly and crushing. In wet discharge, residual charge often remains, sometimes leading to fire accidents.

Notably, Ecosell has technology that enables dry discharge not only at the battery pack and module levels but also at the cell level. While some domestic companies use dry discharge for pre-treatment, Ecosell has secured technology capable of cell-level discharge as well.

They have also secured differentiated raw material extraction technology. Through a direct recycling method that separates used battery electrodes (anode, cathode) and separators, they have developed a simplified technology that selectively extracts raw materials without crushing the used batteries.

Plans to pioneer the global market are also underway. Recently, Kim Sung-moon, chairman of DIC, visited Germany, a leading country in used battery recycling technology, and after persistent efforts to recruit top local engineers, he secured their participation in the Ecosell business soon. The company plans to expand global production facilities and sales networks using plants in Frankfurt, Germany, and Kentucky, USA.

After investments in facilities and technology acquisition efforts, Ecosell began generating sales in the used battery sector this year. Starting with sales of about 80 million KRW this year, they expect sales of 27.1 billion KRW next year and 368.1 billion KRW in 2025 from the used battery sector. Considering the market growth speed and technological advantages, sales are projected to exceed 1.1 trillion KRW by 2027.

A DIC official stated, "The sales estimate of exceeding 1 trillion KRW in four years is based on a fairly conservative market environment assumption," adding, "Achieving even higher sales is definitely possible." The official also said, "Operating profit margins in the used battery sector are expected to remain high at around 15-20%."

The parent company, DIC, will begin full-scale production at its U.S. plant starting next year. DIC owns a factory of about 8,000 pyeong (approximately 26,400 square meters) in the Murray City industrial complex in Kentucky and is currently installing production equipment there. From next year, it plans to produce gears for Hyundai-Kia vehicles and later manufacture EV reducers and EV drive modules. A DIC official said, "With the recovery of the China plant, which had been a bottleneck, and the start of operations at the U.S. plant, the performance improvement trend will become steeper."

Recently, DIC completed the development of a high-output cycloidal reducer, an essential component for industrial robots and collaborative robots, and is conducting system and detailed part designs for about 15 types. A DIC official expressed confidence, saying, "Sales of automotive gear parts and EV reducers are steadily increasing," and added, "We will also demonstrate quick results soon in the used battery business and robot reducer sectors."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)