Honda's 5.1 Trillion Won Investment Joint Venture Continues

Collaboration with World's No.1 Car Seller

Mass Production Technology Reaffirmed

US Michigan Plant as Core Base

Accumulated Extensive Local Production Experience

LG Energy Solution Vice Chairman Kwon Young-soo

"Full Support for Smart Factory"

LG Energy Solution will supply the largest-scale battery through a single order contract to Toyota, the world's number one automobile company.

On the 5th, LG Energy Solution announced that it had signed a large-scale long-term supply contract for electric vehicle batteries with Toyota Motor Corporation of Japan, amounting to 20GWh (gigawatt-hours) annually. This contract is the largest single order contract for LG Energy Solution excluding joint venture (JV) factories. Battery modules equipped with high-nickel NCMA (nickel-cobalt-manganese-aluminum) based pouch cells will be supplied.

Continuous Cooperation with Japanese Automakers: "Korean Batteries with Technology and Mass Production Capability Are Essential"

One GWh of batteries corresponds to the amount used in 12,000 electric vehicles, and LG Energy Solution will supply batteries for approximately 240,000 electric vehicles to Toyota. To this end, LG Energy Solution plans to invest a total of 4 trillion KRW in its Michigan plant in the United States from the end of this year through 2025 to establish dedicated battery cell and module production lines for Toyota. With this contract, LG Energy Solution will supply batteries to all five major global automakers (Toyota, Volkswagen, Renault-Nissan, Hyundai Motor, and GM).

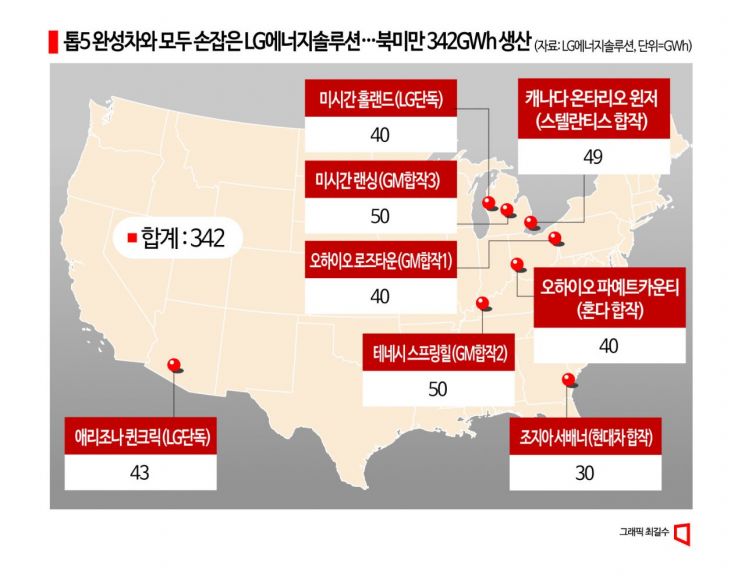

LG Energy Solution currently operates and constructs two standalone plants and six joint venture plants in North America. Including the additional capacity from the Toyota supply, production capacity will increase to 342GWh after 2026. This will enable battery production for approximately 4.1 million electric vehicles. As of the end of June this year, LG Energy Solution's cumulative order backlog stands at 440 trillion KRW.

LG Energy Solution's cooperation with major Japanese automakers is the second after Honda. Japanese companies, which have focused on securing electric vehicle supply chains centered on domestic companies, have ultimately reached out to LG Energy Solution, which possesses battery technology and mass production capabilities. Previously, LG Energy Solution also agreed to invest a total of 5.1 trillion KRW with another Japanese automaker, Honda, to build a joint venture plant in Ohio, USA, with an annual production capacity of 40GWh.

Professor Kim Pil-su of Daelim University’s Department of Automotive Studies said, "While domestic battery companies are building large-scale base plants in the North American market, Panasonic is the only major Japanese battery company that has entered the U.S. market," adding, "For Japanese automakers to thrive in the electric vehicle market, smooth battery supply is essential, so cooperation with domestic companies like LG Energy Solution is necessary." LG Energy Solution expects this order to expand its dominance in the North American market and enhance its ability to respond to the U.S. Inflation Reduction Act (IRA). A representative from LG Energy Solution said, "This order was possible because of the expertise and trust accumulated over many years," and added, "We expect it to be an opportunity to further strengthen our competitiveness in the North American market."

North America's ‘Mother Factory’ Michigan Plant

The batteries supplied to Toyota will be produced at LG Energy Solution’s North American standalone production subsidiary, the Michigan plant (ESMI). The Michigan plant is LG Energy Solution’s first overseas factory, operating since 2013. It serves as a foothold in the North American market and is the ‘mother factory’ (core production base). With the construction of a dedicated Toyota line, the Michigan plant’s production capacity will expand to a total of 40GWh.

For LG Energy Solution’s new plants to operate stably, the operational know-how and the introduction and diffusion of new technologies from the existing Michigan plant are essential. LG Energy Solution explained, "The smooth ramp-up of the first phase of Ultium Cells, a joint venture with GM that started operation at the end of last year, was based on the long-standing local production experience and know-how of the Michigan plant."

In a town hall meeting with employees held during his visit to the Michigan plant in May this year, Kwon Young-soo, Vice Chairman of LG Energy Solution, said, "The Michigan plant should be the North American ‘mother factory’ where advanced technologies are first introduced and where it supports and complements issues at other plants," adding, "To this end, we will provide full support to strengthen the smart factory capabilities of the Michigan plant and the growth of its workforce."

Synergy Expected from Combining LG Energy Solution’s Cell and Module with Toyota’s Pack Technology

The two companies expect to produce batteries with enhanced safety and performance by combining LG Energy Solution’s cell and module technology with Toyota’s pack technology. LG Energy Solution holds over 29,000 patents and has a global production capacity of 200GWh annually.

In fact, through this collaboration, LG Energy Solution has demonstrated its technological prowess by achieving meaningful results such as improving thermal management technology based on high-nickel NCMA (nickel-cobalt-manganese-aluminum). Toyota also showcases high-level battery pack technology based on its self-developed platform and manufacturing know-how of over 10 million vehicles annually. The two companies expect that the innovative batteries created by combining their technologies will provide new momentum for Toyota electric vehicles in the transition of the North American electric vehicle market.

Toyota recorded sales of 371 trillion KRW last year and is the world’s top-selling automobile company by volume. It also ranks second in vehicle sales in North America after GM, demonstrating its strong influence. Recently, Toyota announced plans to launch 30 electric vehicle models by 2030 and sell 3.5 million units annually in the global market, accelerating its electrification strategy.

Detsuo Ogawa, CEO of Toyota Motor North America, said, "Toyota aims to reduce carbon dioxide emissions as quickly as possible and is targeting expanded electric vehicle sales in North America," adding, "We are very pleased to cooperate with LG Energy Solution to provide products with high safety, performance, and quality that meet customer expectations."

Kwon Young-soo, Vice Chairman of LG Energy Solution, stated, "The new cooperation between Toyota, the world’s number one global automaker, and LG Energy Solution, a leading battery company, will be a major step forward for the North American electric vehicle market," and added, "Through this collaboration, we will further strengthen our North American production network and enhance the competitiveness of innovative products to provide the world’s best customer value."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.