K-Battery, Equipment Also Crossing Borders - Part 2

Electrode, Assembly, Activation, Inspection, and More

Korean Equipment Companies with Technology Expertise in Every Battery Process

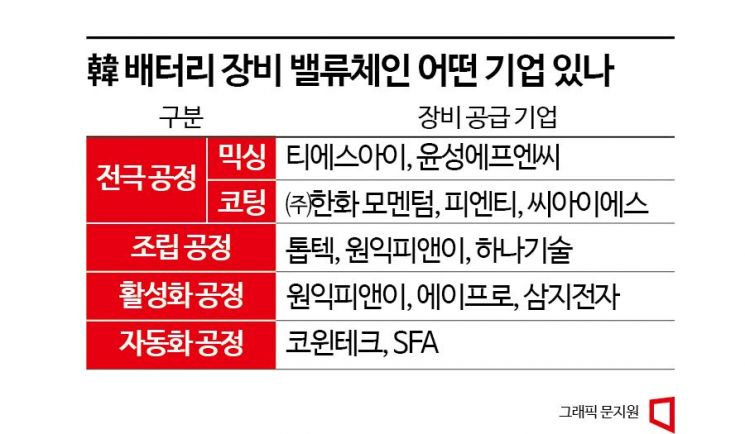

The battery manufacturing process is broadly divided into four stages: electrode → assembly → activation (formation) → inspection. Our equipment companies have developed machinery tailored to each detailed battery process, such as mixing, pressing, cutting, and aging.

First, the electrode (plate) process is the manufacturing step that produces the basic cathode and anode of the battery. Process equipment that enhances performance and manufacturing efficiency is required. Depending on the product type and form factor (classification by shape), the first step is the mixing process, where measured active materials (substances that generate electrical energy), conductive agents (materials that facilitate electron movement), and binders (materials that help bond and coat the components) are blended. Equipment from companies such as TSI, Yoonseong FNC, and Jeil M&S is used in the mixing process. Next, a thin coating of copper foil and aluminum foil is applied to the electrode and dried, which is called the coating process. Coating equipment is produced by companies like Hanwha Momentum, CIS, and PNT.

Afterward, the electrode passes between two large rolls to be flattened. This removes unnecessary spaces between particles and increases energy density. Roll pressing equipment from CIS and PNT is used in this process. The flattened electrode is then cut horizontally according to size (slitting) and then cut vertically (notching), completing the electrode process.

The completed electrodes then undergo assembly according to the form factor, such as pouch, prismatic, or cylindrical. The cathode, anode, and separator are stacked (stacking), folded (folding), or wound (winding) layer by layer, placed into a pouch or aluminum can, and electrolyte is injected. This process completes the battery form. Companies like Toptec, Wonik PNE, and Hana Technology manufacture assembly process equipment.

The activation process involves embedding the battery characteristics. In this step, the battery is charged and discharged to "age" and activate it. Aging is a process where the battery is stored for a set time under specified temperature and humidity conditions to sufficiently disperse the electrolyte inside the battery, optimizing ion movement. Equipment from Wonik PNE, A-Pro, and Samji Electronics is used. Afterwards, inspection equipment checks for defective cells, and after packaging, the battery is ready for the market. The investment ratio in equipment by battery process is generally 30% for electrode process, 17% for assembly process, 29% for activation process, and 24% for inspection and automation processes.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)