Ulsan National Institute of Science and Technology (UNIST) conducted a study on the electric production system of ammonia, used as an efficient medium for hydrogen transportation, and the optimization of its import.

The research team led by Professor Lim Han-kwon from UNIST’s Graduate School of Carbon Neutrality and Department of Energy and Chemical Engineering carried out a study titled “Expansion and Optimization of Ammonia Imports for Electricity Production in Korea.”

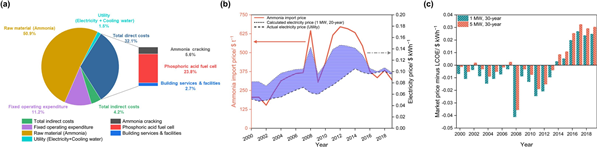

In this study, a small-scale distributed power generation facility was designed by combining an ammonia decomposition system with a phosphoric acid fuel cell, and scenarios were established based on the import volume according to different ammonia production methods to optimize the system.

Distributed power generation systems consist of small power generation units geographically dispersed rather than centralized power plants, offering advantages such as reduced power loss and improved stability of power supply.

The research team studied process design considering the entire lifecycle from ammonia production to utilization, technology and economic feasibility, environmental assessment, and import optimization to use ammonia as a raw material in the system.

To this end, the top 10 countries accounting for more than 80% of Korea’s ammonia imports were selected based on statistical data, including Indonesia, the United States, and Saudi Arabia.

Ammonia was categorized by production method into “carbon-based ammonia,” produced from fossil fuels, and “carbon-neutral ammonia,” produced from fossil fuels but with carbon dioxide removed through a carbon capture system.

The research team set scenarios according to the import ratio of these two types of ammonia and derived the optimal ammonia import conditions that ensure economic and environmental feasibility based on Korea’s actual ammonia import records over the past 20 years.

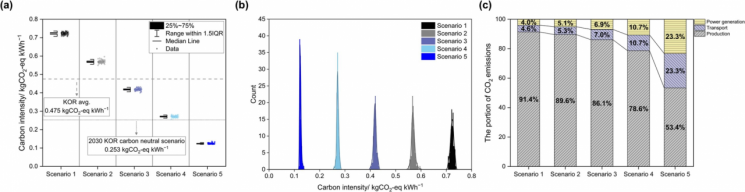

The study confirmed that the ammonia production method has the greatest impact on carbon intensity, an indicator of carbon dioxide emissions.

The team found that if Korea increases the proportion of carbon-neutral ammonia used for hydrogen production to 78%, it can achieve the 2030 carbon intensity target, an intermediate goal for achieving “carbon neutrality by 2050.”

Additionally, the results showed that electricity production using carbon-neutral ammonia is sufficiently competitive in reducing carbon dioxide emissions.

Dongjun Lim, first author and integrated MS-PhD course researcher in the Department of Energy and Chemical Engineering, explained, “Ammonia, which contains no carbon but includes hydrogen, is attracting attention as an efficient hydrogen carrier and can offer several advantages if used as a raw material in distributed power generation systems.”

Professor Lim Han-kwon of the Graduate School of Carbon Neutrality and Department of Energy and Chemical Engineering said, “This study provides an integrated analysis of a system that produces electricity from ammonia-derived hydrogen in fuel cells, demonstrating the potential for ammonia utilization in distributed power generation.”

He added, “While we analyzed the final electricity production cost and greenhouse gas emissions considering the price and environmental impact of two commercialized ammonia production methods, this study did not consider methods using renewable energy, and related follow-up research is currently underway.”

This research was conducted with support from the UNIST Carbon Neutral Demonstration Center, the Climate Change Response Technology Development Project of the Ministry of Science and ICT and the National Research Foundation of Korea, and funding from the Ministry of Trade, Industry and Energy through the Korea Institute for Advancement of Technology. It was published online on May 13 in the international journal Chemical Engineering Journal.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.