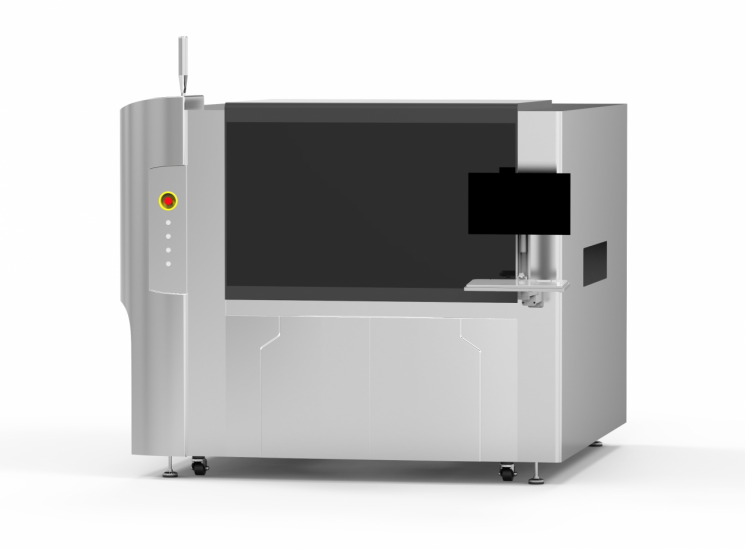

New LC Bonder with Superior Performance Compared to General LSR·LAB

Advanced Semiconductor Equipment LC Bonder·LSR Series Surface Light Source Laser Technology

Targeting CoWoS Packaging... Leading Surface Laser Technology Company

LaserCell, a leading company in surface light source laser platforms, expects to ride the semiconductor boom as demand for artificial intelligence (AI) semiconductors increases.

On the 12th, LaserCell announced that it produces various surface laser-based semiconductor equipment, including its self-developed 'LC Bonder' and the 'LSR Series.'

A company representative explained, "We are conducting exclusive equipment tests for business cooperation with various global semiconductor companies," and added, "Demand for LaserCell's LC Bonder and LSR Series equipment is expected to increase explosively."

He continued, "The technology attracting attention in the global semiconductor market is the advanced AI semiconductor core technology called ‘Chip-on-Wafer-on-Substrate’ (CoWoS) packaging technology."

CoWoS packaging adopts a method of ultra-fine and ultra-precise bonding of multiple memory semiconductors and logic semiconductors onto a silicon-based substrate plate called an ‘interposer.’ The core of the technology is arranging memory semiconductors and logic semiconductors flat on the interposer or stacking them vertically. Because it combines 2D and 3D forms, it is also called ‘2.5D packaging.’

The representative explained, "The distance between semiconductors becomes closer, reducing the mounting area and speeding up connections between chips," and added, "Because it allows installation of a large amount of wiring, CoWoS packaging technology is preferred."

He emphasized, "LaserCell’s independently developed advanced semiconductor equipment, the LC Bonder and LSR Series, are surface laser devices optimized for the CoWoS packaging process."

The method of stacking memory semiconductors or logic semiconductors vertically on the interposer is called stacking. Heterogeneous bonding is a method of attaching logic semiconductors flat. Mainly, TC Bonder equipment is used. The TC Bonder heats a ceramic header, a kind of robotic arm, to press the interposer and chips one by one for bonding. Using the TC Bonder makes it difficult to shorten production process time because chips are bonded individually.

A LaserCell representative said, "The LC Bonder, which applies LaserCell’s world-class surface light source laser technology, can bond stacking and heterogeneous bonding at once," and introduced, "LaserCell possesses technology that uses a large-area laser light source of 300mm x 300mm, the world’s largest scale, to bond ultra-finely and ultra-precisely with purely in-house technology."

He added, "LaserCell is currently recognized as the world’s top specialized company in the global surface laser field, successfully conducting direct tests and actual applications with top-tier semiconductor companies." Furthermore, he noted, "The method of simultaneously performing vertical laser irradiation and pressing stages using large-diameter quartz material, a proprietary patented technology, is unique to LaserCell worldwide."

LaserCell’s LC Bonder can relatively reduce process time compared to the TC Bonder method. LaserCell was the first in the industry to supply LSR equipment to Taiwanese foundry company A. This equipment was used in the advanced semiconductor laser bonding process supplied to the world’s largest electronics manufacturer. The company emphasized that LaserCell is the only company to succeed in applying large-area surface light source laser technology to cutting-edge mass production processes.

With the increase in AI semiconductor demand, advanced semiconductor and foundry production volumes are expected to rise, leading to increased demand for bonding equipment. This is why LaserCell expects external growth in the second half of the year.

A LaserCell representative said, "Although we posted results that fell short of shareholders’ expectations due to the global semiconductor market downturn, we are now entering a semiconductor market recovery phase with continued expansion of the advanced semiconductor packaging market." He added, "We are conducting tests on the existing flagship LSR Series and the newly announced LC Bonder version optimized for AI semiconductors and advanced semiconductors," and expressed expectations for improved performance.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)