SK Shieldus, Industrial Safety Monitoring at a Glance

Solution for Fall Accident Prevention Included

With the first guilty verdict against a corporate CEO for violating the Serious Accident Punishment Act, interest in safety solutions that can prevent industrial accidents in advance is increasing. There is no disagreement that preventing fall accidents, which account for more than half of construction industry accidents, is the best way to avoid risks under the Serious Accident Punishment Act. To this end, companies applying advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) to collect and analyze data related to industrial safety activities and provide solutions are gaining attention.

SK Shieldus offers the integrated safety management platform service ‘SUMiTS Industrial Safety,’ which connects sensors, devices, and CCTV related to industrial safety for comprehensive monitoring at a glance. It is said to have a differentiated advantage in that it can identify risk factors in advance according to the requirements of the Industrial Safety and Health Act and integrate worker safety management, equipment safety management, and environmental management into a single platform.

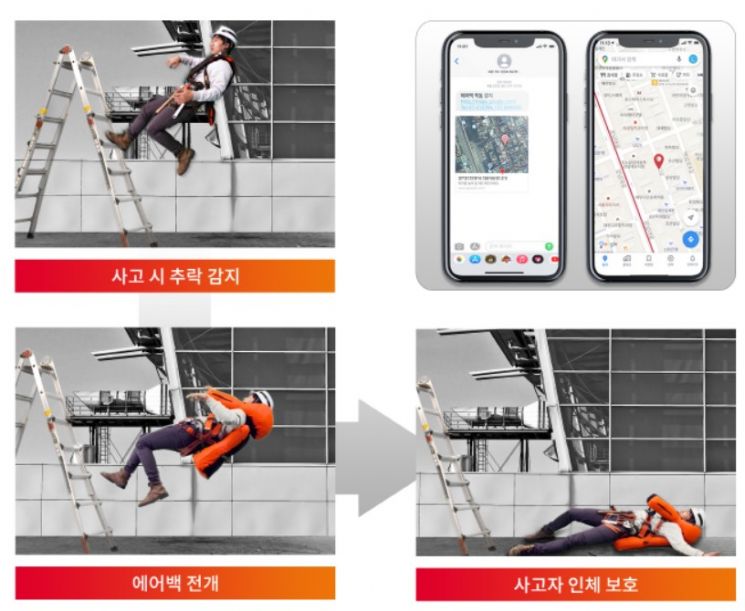

SK Shieldus also presents customized industrial safety solutions for short-term sites or small and medium-sized enterprises where platform adoption is difficult. The ‘Wearable Airbag’ is a solution that protects workers’ safety against fall accidents. It is equipped with a gyro sensor and an acceleration sensor that can detect a worker’s fall, automatically inflating within 0.2 seconds upon a fall accident to cushion the impact. At the same time as the fall, it sends a text message with the accident victim’s location to the site manager to assist in prompt follow-up action.

Hyundai Elevator has a ‘Smart Safety System’ that helps minimize the possibility of fall accidents. It consists of a safety helmet, safety hook, and safety belt sensors equipped with IoT sensors, a worker-exclusive application (app), and a control platform. When a worker installs an elevator at a high place, big data-based machine learning technology automatically checks whether the safety helmet chin strap and safety hook are fastened, and if not fastened, it notifies the worker and those nearby to prevent danger in advance.

POSCO ICT supports the ‘Smart Safety Control Platform,’ which integrates safety management for manufacturing, construction, and plant sites. It is a solution that collects and analyzes site data through various sensors to monitor risk factors and disseminate results to on-site workers to help prevent safety accidents. AI-based facial recognition technology is applied to monitor unauthorized access to hazardous areas and the status of safety equipment wearing. In connection with smart CCTV, it also detects unstable abnormal behavior of workers and fires within the workplace.

An industry official said, "With the application criteria of the Serious Accident Punishment Act expanding to workplaces with 5 to fewer than 50 employees from next year, interest in solutions that can prevent industrial safety accidents is expected to increase," adding, "It is important for industrial safety solutions to quickly identify and respond to threats on site."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.