Hyundai Motor and SK to Invest 6.6 Trillion KRW in US Joint Venture Plant

Mass Production Expected by 2025

Annual Electric Vehicle Capacity of 500,000 Units

Early Production Meets Tax Credit Requirements

Final Investment Details to Be Approved by Board

[Asia Economy Reporter Choi Dae-yeol] Hyundai Motor Group and SK On have decided to build a joint electric vehicle battery plant in the state of Georgia, USA. The new dedicated electric vehicle plant Hyundai Motor Group plans to build will be located near two existing vehicle assembly plants and SK's battery plant. The state government expects battery mass production to be possible by 2025, when Hyundai's new plant is scheduled to begin operations.

Brian Kemp, Governor of Georgia, USA, announced on the 8th (local time), "Hyundai Motor and SK On will build a battery manufacturing facility in Bartow County, investing between $4 billion and $5 billion (approximately 5.3 trillion to 6.6 trillion KRW) to create more than 3,500 jobs." Specific investment amounts, joint venture methods, and plant size will be finalized after approval by the boards of both companies.

The site for the new plant is located about 100 km northwest of Atlanta, the capital of Georgia. It is about a 4-hour drive from the Savannah area on the East Coast, where Hyundai aims to operate a dedicated electric vehicle plant by 2025, and 3 to 4 hours from the currently operating Alabama (Hyundai) and Georgia (Kia) vehicle assembly plants. It is also about 2 hours away from SK's Georgia plant, which is currently in mass production.

Chairman Chung Eui-sun of Hyundai Motor Group (left in the photo), Georgia Governor Brian Kemp, and Hyundai Motor Global Chief Operating Officer Jose Munoz are holding glasses handed by Boston Dynamics' quadruped robot 'Spot' during the groundbreaking ceremony for the new electric vehicle plant last October, celebrating with a commemorative toast.

Chairman Chung Eui-sun of Hyundai Motor Group (left in the photo), Georgia Governor Brian Kemp, and Hyundai Motor Global Chief Operating Officer Jose Munoz are holding glasses handed by Boston Dynamics' quadruped robot 'Spot' during the groundbreaking ceremony for the new electric vehicle plant last October, celebrating with a commemorative toast. If the investment proceeds as announced by the state government, the battery plant is expected to have an annual production capacity of 45 GWh. Considering the large battery capacity required for locally produced vehicles such as large sport utility vehicles (SUVs) and pickup trucks, this is estimated to be enough for 500,000 electric vehicles.

What draws attention is the proposed completion date of the plant in 2025. Initially, the industry expected that discussions on Hyundai's U.S. battery joint venture would be prolonged, and local battery supply would only be possible around 2026. Jose Munoz, Hyundai Motor's Chief Operating Officer (COO) and Head of North America, stated at an analyst meeting last month that the joint venture operation would begin in "the first quarter of 2026."

Under the already implemented Inflation Reduction Act (IRA), only electric vehicles that undergo final assembly locally or meet battery raw material requirements are eligible for a $7,500 (approximately 10 million KRW) tax credit. It is interpreted that efforts are underway to advance the battery mass production timeline as much as possible to meet these criteria.

Choi Jae-won, Senior Vice Chairman of SK Group (left), and Andy Beshear, Governor of Kentucky, signed the H-beam at the groundbreaking ceremony of the BlueOval SK Kentucky plant held on the 5th (local time) in Glendale, Kentucky, USA.

Choi Jae-won, Senior Vice Chairman of SK Group (left), and Andy Beshear, Governor of Kentucky, signed the H-beam at the groundbreaking ceremony of the BlueOval SK Kentucky plant held on the 5th (local time) in Glendale, Kentucky, USA. Hyundai Motor is aiming to build the new plant by the first half of 2025, while converting some internal combustion engine production lines at existing vehicle assembly plants this year and next to promote local production. Considering that building a large-scale electric vehicle battery plant typically takes about 2 years and 6 months to 3 years, the construction schedule for the joint battery plant by the two companies is expected to be quite tight.

It is also reported that the battery joint venture plan between Hyundai Motor and LG Energy Solution is in the final stages of coordination. According to industry sources, senior LG executives recently visited the new Hyundai plant site in Savannah to inspect the location. Currently, it is highly likely that the Hyundai-LG battery joint venture plant will be located within the new electric vehicle plant site.

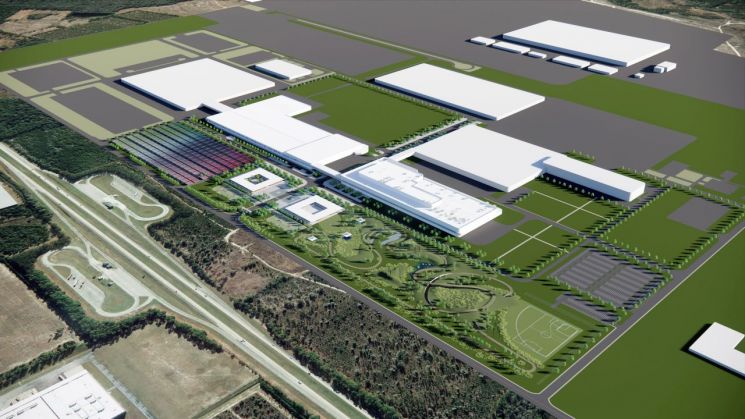

The Mega Plant America (HMGMA) site that Hyundai Motor Group is building on the east coast of Georgia covers 11.83 million square meters, which is about twice the size of Hyundai Motor's Ulsan plant (5.19 million square meters), considered the world's largest single vehicle assembly plant. From the beginning of selecting the new plant site, Hyundai Motor planned to place the battery joint venture plant nearby. The battery joint venture plant with LG is expected to be similar in size or somewhat smaller than SK's.

Aerial view of Hyundai Motor Group's mega plant America (HMGMA) to be established in Savannah, Georgia, USA

Aerial view of Hyundai Motor Group's mega plant America (HMGMA) to be established in Savannah, Georgia, USA Hyundai Motor Group announced a mid-to-long-term plan this year to sell 3.23 million electric vehicles worldwide by 2030. Of these, about 840,000 units are expected to be sold in the United States alone. Even if the Inflation Reduction Act does not apply to some commercial and other electric vehicle uses, Hyundai Motor Group needs additional battery supply sources to smoothly operate its electric vehicle business locally. Hyundai is reportedly discussing joint ventures or long-term supply contracts with other global battery cell manufacturers besides LG and SK.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.