Joint Venture P&O Chemical to Complete 50,000-ton Annual Hydrogen Peroxide Plant in Gwangyang, Jeonnam on the 20th

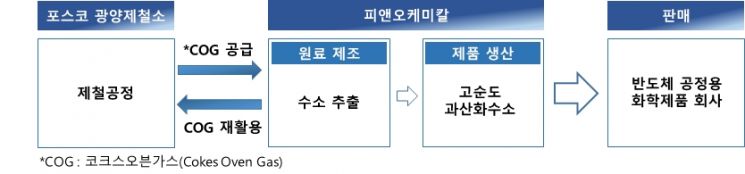

POSCO Chemical and OCI are entering the production of hydrogen peroxide, an essential material for semiconductor processes. By utilizing hydrogen extracted from coke oven gas generated during the steelmaking process for the first time in Korea, they have enhanced both economic efficiency and environmental friendliness.

On the 20th, P&OChemical, an advanced chemical materials joint venture between POSCO Chemical and OCI, held a completion ceremony for a hydrogen peroxide plant at the National Industrial Complex in Gwangyang, Jeollanam-do. The event was attended by business officials including Min Kyung-jun, President of POSCO Chemical; Kim Taek-jung, President of OCI; Kim Jong-guk, President of P&OChemical; Yoo Byung-ok, Head of the Eco-friendly Future Materials Team at POSCO Holdings; and Jeong In-hwa, Mayor of Gwangyang.

P&OChemical invested 145.9 billion KRW in a 41,530㎡ site within the Gwangyang National Industrial Complex to complete a plant with an annual production capacity of 50,000 tons. Hydrogen peroxide (H₂O₂) is an oxidizing agent used for bleaching and disinfection. This plant produces electronic-grade products essential for cleaning and etching processes of semiconductor wafers and display substrates, as well as industrial-grade products used for general bleaching and disinfection.

Through this, they can stably supply high-purity hydrogen peroxide that is economical and eco-friendly to domestic semiconductor customers, whose demand is rapidly increasing due to large-scale production line expansions and additional process steps.

P&OChemical is the first in Korea to produce hydrogen peroxide using raw materials extracted from coke oven gas generated during the steelmaking process. Coke oven gas is a byproduct gas produced when coal is processed at high temperatures in coke ovens during steelmaking, mainly composed of hydrogen and methane. Compared to the existing LNG (liquefied natural gas) extraction method, this approach allows raw material recycling, making it economical and reducing carbon emissions by about 29%, thus being environmentally friendly. By connecting pipelines with the Gwangyang Steelworks, coke oven gas generated during the steelmaking process is supplied to extract and purify hydrogen. The coke oven gas, after hydrogen extraction, is returned to the steelworks and reused as a heat source.

By entering the hydrogen peroxide business, POSCO Chemical has expanded its product portfolio beyond battery materials to advanced chemical materials such as semiconductors, securing new growth engines. Additionally, producing chemical products using byproducts from the steelmaking process maximizes the added value of its carbon materials business.

OCI, based on its accumulated technological expertise, has stably produced high-purity hydrogen peroxide for semiconductor processes, further expanding its market dominance. OCI has been producing hydrogen peroxide since 1979, and with the completion of this plant, total production capacity will increase from the existing 75,000 tons to 125,000 tons.

At the event, Min Kyung-jun, President of POSCO Chemical, said, "We have advanced our business model into high value-added materials and secured growth engines. We are pleased to contribute to the development of domestic industry by stably supplying essential materials for the semiconductor industry through close cooperation with OCI."

Kim Taek-jung, President of OCI, stated, "P&OChemical has taken the first step toward leading the high value-added materials market through the collaboration between OCI and POSCO Chemical. We will continue to strengthen strategic cooperation based on OCI’s technology, quality, and safety to develop P&OChemical into a global advanced precision chemical materials company."

P&OChemical, established in July 2020 as a joint venture with POSCO Chemical holding 51% and OCI 49%, is promoting advanced chemical materials businesses such as pitch for anode materials in addition to hydrogen peroxide. Both companies plan to continue pursuing various high value-added materials businesses based on raw materials and technological competitiveness.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)