Maximizing Competitiveness in Electrolyte Organic Solvent Business for Electric Vehicle Lithium-Ion Batteries

Domestic First Development of EMC and DEC Proprietary Technologies

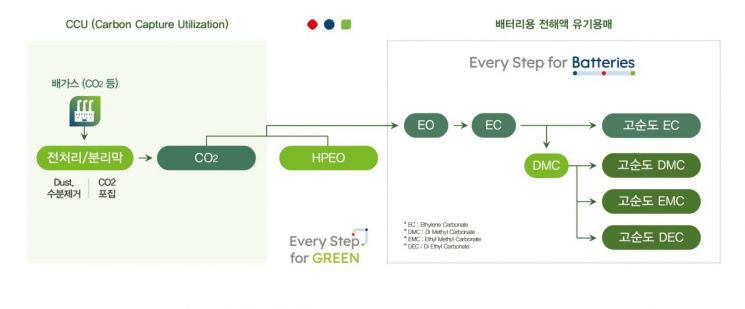

Lotte Chemical's value chain of organic solvents for lithium-ion battery electrolytes. Data provided by Lotte Chemical

Lotte Chemical's value chain of organic solvents for lithium-ion battery electrolytes. Data provided by Lotte Chemical

[Asia Economy Reporter Donghoon Jeong] Lotte Chemical announced on the 29th that it will be the first in Korea to promote the production of EMC (Ethyl Methyl Carbonate) and DEC (Diethyl Carbonate), organic solvents for battery electrolytes, through in-house technology development.

Last May, Lotte Chemical announced the construction of a factory for EC (Ethylene Carbonate) and DMC (Dimethyl Carbonate), the first domestic organic solvents for battery electrolytes, at its Daesan plant in Seosan, Chungnam, investing about 210 billion KRW. Additionally, it plans to invest about 140 billion KRW to expand production to include EMC and DEC. This means that all four types of organic solvents used in the electrolyte, one of the four core components of lithium-ion batteries, will be produced. These solvents account for about 30% of the electrolyte cost.

Lee Young-jun, Head of Lotte Chemical's Battery Materials Business Unit (CEO), said, "We will strive to expand materials for lithium-ion batteries through active battery material technology development and related business cooperation within the group," adding, "We will contribute to strengthening the competitiveness of the domestic materials industry through technology development and localization, helping Korea become a global powerhouse in materials, parts, and equipment."

Lotte Chemical is establishing a business for electrolyte organic solvents, including the construction of in-house production facilities for key raw materials (HPEO, CO2), which will enable stable product supply to customers and a competitive business structure. Furthermore, the CO2 capture facility under construction at the Daesan plant will utilize captured CO2 as raw material for high-purity EC and DMC, serving as a measure to respond to the climate crisis and achieve carbon neutrality.

Meanwhile, Lotte Chemical continues to actively invest in future battery material businesses. In January this year, it invested 65 billion KRW in Standard Energy, which developed the world's first vanadium ion battery, recognized as the next-generation battery for energy storage systems (ESS), securing a 15% stake as the second-largest shareholder. In April, it signed a memorandum of understanding (MOU) to establish a joint venture (JV) with SOELECT, a U.S. startup developing lithium metal anode materials and solid electrolytes, key materials for next-generation batteries, to build a gigawatt-scale (GWh) lithium metal anode production facility worth about 200 million USD in the U.S. by 2025.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.