POSCO and Daewoo Shipbuilding & Marine Engineering

Core Material for Eco-Friendly Fuel Propulsion Ships

High-Manganese Steel LNG Fuel Tank

World's First Installation on a Ship

China's Production Volume 31.67 Million Tons Last Year

Formation of 'Manganese Alliance' Last Year

Attempt to Control Raw Material Prices

Experts Warn "High Dependence on China Should Be Cautioned"

[Asia Economy Reporter Jeong Dong-hoon] Manganese, a metal that is hard yet brittle, has recently expanded its industrial applications from steel and shipbuilding to the battery sector. When alloyed with iron, manganese enhances strength and improves battery stability, making it a metal re-evaluated as ideal for the eco-friendly era. However, concerns have been raised about the need to reduce dependence on imports from China, which dominates supply.

According to the industry on the 21st, POSCO and Daewoo Shipbuilding & Marine Engineering recently applied high-manganese steel, which uses manganese as an alloying material, to LNG (liquefied natural gas) fuel tanks on LNG vessels for the first time in the world. The two companies developed the high-manganese steel after more than ten years of joint research. LNG fuel tanks are key equipment for eco-friendly fuel-powered ships.

LNG must be stored in fuel tanks and cargo holds at an ultra-low temperature of minus 163 degrees Celsius to maintain its liquefied state. To achieve this, expensive nickel alloy steel, aluminum, and stainless steel have been used for LNG fuel tanks. These materials are not only costly but also difficult to work with and have low strength. However, the newly developed high-manganese steel LNG fuel tank is less expensive than existing materials and offers high strength and wear resistance as well as excellent performance at ultra-low temperatures.

On March 17, visitors to 'InterBattery 2022' held at COEX in Samseong-dong, Gangnam-gu, Seoul, are examining a POSCO battery pack model for electric vehicles using composite materials at the POSCO Chemical exhibition hall. / Photo by Hyunmin Kim kimhyun81@. The photo is not directly related to the article.

On March 17, visitors to 'InterBattery 2022' held at COEX in Samseong-dong, Gangnam-gu, Seoul, are examining a POSCO battery pack model for electric vehicles using composite materials at the POSCO Chemical exhibition hall. / Photo by Hyunmin Kim kimhyun81@. The photo is not directly related to the article.

In steel products, manganese is used as an alloying material to increase the strength of steel. When sulfur content is high in steel, iron sulfide (FeS) forms, causing the steel to become brittle. Manganese is used to control sulfur (S), thereby enhancing the strength and durability of steel. Additionally, manganese combines with oxygen to prevent bubbles or micro-holes from forming inside steel products.

Manganese is also a key raw material used in batteries. It improves battery stability and is used in battery cathode materials. Although manganese deposits are evenly distributed worldwide in countries such as South Africa, Brazil, and Australia, China overwhelmingly leads in production. According to the Korea Resources Information Service, China’s manganese production last year reached approximately 31.67 million tons, double that of South Africa, the second-largest producer, at 16.02 million tons.

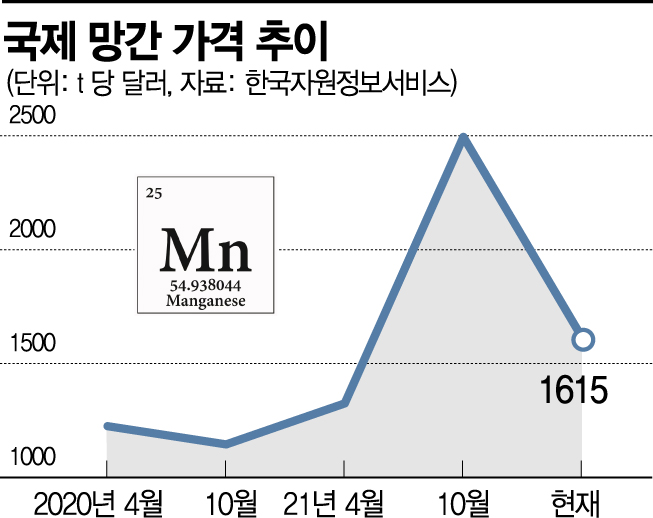

Domestic battery manufacturers mainly produce ternary or quaternary batteries using NCM (nickel, cobalt, manganese) as the primary material, increasing manganese’s domestic demand. Compared to cobalt (around $59,000 per ton), manganese (around $1,000 to $2,000 per ton) is cheaper, leading to a growing proportion of manganese in battery cells. However, concerns have been raised about excessive dependence on Chinese imports. According to the Korea International Trade Association, 99% of manganese imports come from China. This is higher than other materials such as aluminum cables (97.4%), magnesium ingots and scrap (94.5%), galvanized steel sheets (93.8%), and graphite (87.7%), indicating near-total reliance on China for manganese imports.

China holds manganese reserves of 203 million tons, enabling it to weaponize the resource at any time. Possessing natural manganese resources worth 100 billion yuan (approximately 17 trillion won), China formed the “Manganese Alliance” last year to attempt controlling global prices of raw materials ranging from iron ore to nickel and manganese.

Professor Kim Pil-su of the Department of Future Automotive Engineering at Daelim University said, “It is time for the government to step in and establish a system that can stably supply raw materials through international agreements.” He added, “Especially for batteries and other key raw materials needed in the Fourth Industrial Revolution era, it is necessary to reduce dependence on China, which practically monopolizes these resources.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.