[Interview] Jung Taeksu, CEO of Netspa, Aims to Process 50% of Discarded Waste Fishing Nets

"Will Grow by Raising Recognition as a Recycling Material Specialist in the Global Market"

[Asia Economy Reporter Kim Jonghwa] Netspa is a company that collects and processes discarded fishing nets, a representative marine waste that disrupts marine ecosystems, to produce recycled nylon.

In South Korea, 44,000 tons of discarded fishing nets are thrown away annually. However, only about 10%, or 4,400 tons, are collected. Netspa converts 60% of the collected discarded fishing nets into "recycled nylon," and the remaining 40% into "engineering plastics," a high-performance plastic material that can replace metals or ceramics. The recycled nylon is reborn as long fibers for clothing at textile companies, while the engineering plastics are used as raw materials by chemical companies to manufacture smartphones, laptops, and more.

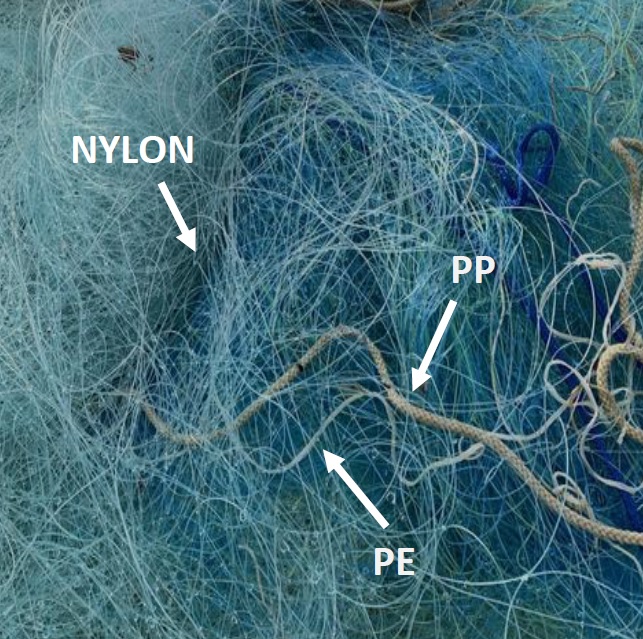

Discarded fishing nets are composed solely of synthetic fibers such as nylon (PA6), polypropylene (PP), and polyethylene (PE). Unlike other wastes containing large amounts of additives, they consist only of single materials, making them one of the wastes with high recycling value. While general waste causes environmental pollution and follows a recycling process, discarded fishing nets themselves have high recycling value, making them popular as recycled materials. However, the amount of collected discarded fishing nets is small, and the recycling process is not easy, resulting in high entry barriers.

Before Netsupa developed automatic separation technology, nylon, polypropylene (PP), and polyethylene (PE) had to be manually sorted by hand.

Before Netsupa developed automatic separation technology, nylon, polypropylene (PP), and polyethylene (PE) had to be manually sorted by hand. [Photo by Netsupa]

The process and technology to separate major components such as nylon are the core of the discarded fishing net recycling industry. The collected nets must be washed to remove barnacles and various organic materials, finely shredded, and then separated and processed by each component. However, there is no technology to automatically separate these components, so even in Europe and advanced countries, large-scale manual sorting labor has been required.

Netspa brought innovation to the global recycled nylon market by developing technology that automatically sorts and separates finely shredded polymers based on their characteristic differences. CEO Jeong Taeksu, who was in charge of environmental safety at Hyundai Heavy Industries, became interested in eco-friendly clothing and founded a sustainable fashion brand called "Ridley" at the age of 31. CEO Jeong explained the reason for founding the company: "I started an eco-friendly clothing business, but it was difficult to obtain eco-friendly nylon materials. After understanding why, I thought it would be better to produce it ourselves and supply it to the domestic market."

To establish Netspa, on-site investigations of discarded fishing nets were conducted, and various data were collected. Through this, an algorithm to distinguish each component of the discarded fishing nets was developed, and mechanized operations were successfully implemented, leading to patent applications.

Netspa was established in December 2020 and, despite being in the prototype production stage (pilot stage) last year, secured major clients such as Hyosung TNC. Netspa supplies recycled nylon and engineering plastics in the form of pellets to its customers. Last year, it recorded sales of 17.6 million KRW, and this year it expects sales of 3 billion KRW. It also attracted 3 billion KRW in Series A investment from venture capital firms TBT, Magna Investment, and Impact Square.

Customer satisfaction with the quality of the prototypes delivered is also high. Once mass production facilities are completed by mid-next month, the annual processing capacity of discarded fishing nets will increase from the current 2,600 tons to over 4,000 tons. CEO Jeong Taeksu said, "Netspa's technology is not a highly advanced high-tech technology, but the technical operational know-how of key processes is highly evaluated," adding, "This is a market that is emerging worldwide, and international interest is growing, so the growth potential is very high."

Through direct investment from overseas investors, Netspa is preparing to establish factories in developing countries or expand overseas through cooperation with environmental NGOs. Southeast Asian countries such as Indonesia, the Philippines, and Vietnam, where environmental problems caused by discarded fishing nets are severe, are the primary targets for consideration. CEO Jeong expressed confidence, saying, "Within a few years, we will have the capacity to process about 50% of the discarded fishing nets thrown away domestically," and "We will grow by raising our recognition as a specialized recycled material company in the global market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)