The Only Domestic Holder of 'Wet Process' Technology

Manufacturing Cationic Filters for Water Purifiers

Pioneering the Future Mobility Materials Market

Following Japan's export restrictions in 2019, the COVID-19 pandemic, and the Russia-Ukraine war, supply chain risks continue to plague our economy. Disruptions in production processes and logistics due to the global trend of protectionism are also frequent. This has increased the necessity for the localization of materials, parts, and equipment (Sobu-jang).

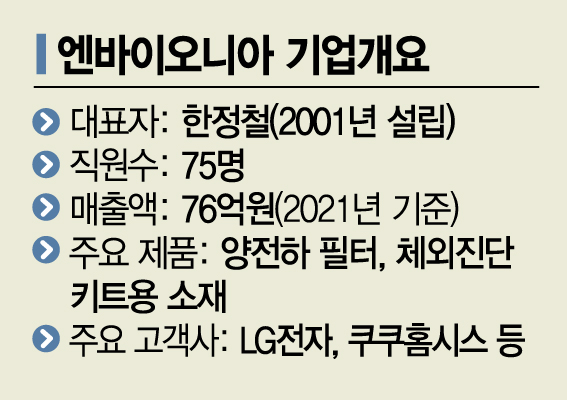

Envionia has attracted attention for pursuing domestic production of materials that were previously dependent on imports while being environmentally friendly. It is the only company in Korea that manufactures high-density, high-quality advanced composite materials through a "wet process." The wet process involves mixing various fiber raw materials, floating them on water, and drying them into thin sheets. This process is similar to traditional Korean paper (Hanji) making. Because the materials developed are lightweight, strong, and eco-friendly, they can be applied in various fields. One of Envionia's main products, the cationic filter, is used in household and industrial water purification filters and accounted for 70% of the company's sales last year.

Han Jeong-cheol, CEO of Envionia (photo), studied trade and economics and worked for six years at the Korea Institute for International Economic Policy. In 2001, he co-founded the company with his wife, Park Seong-eun, who was then the deputy director of Yonsei University's Environmental Pollution Research Institute. At that time, the institute imported expensive virus detection filters from global manufacturers, but they decided to pursue localization of the materials and started the company. Currently, Park serves as Envionia's Chief Technology Officer (CTO).

CEO Han said, "I thought it would take about three years to complete material development, but that was a misjudgment," adding, "It took a full 10 years to go beyond laboratory-level material development to pilot testing and commercialization." The materials industry requires continuous research and development (R&D), and it takes a long time to accumulate technology. Leading advanced materials companies in Japan, such as Toray and Asahi Kasei, have been in business for nearly 100 years.

In the early days of the startup, securing funds for raw material supply and facility construction was not easy. At that time, the materials industry was an unfamiliar field, and investments were concentrated mainly on IT companies, which had relatively shorter investment recovery periods. It was only in 2011 that CEO Han received a total investment of 4 billion KRW from four venture capital firms for the first time. After establishing a factory in Jecheon, Chungbuk, and starting mass production of advanced composite materials, the company succeeded in a technology-specialized stock listing in 2019. At the time of listing, the company's valuation was about 60 billion KRW, about ten times higher than five years earlier.

The materials produced by Envionia are applied in water purifiers and air purifier filters manufactured by large corporations such as LG Electronics. Additionally, leveraging experience and know-how from producing pregnancy test kits in 2013, the company is manufacturing pads for COVID-19 and malaria diagnostic kits. They are also pioneering the materials market for future mobility such as electric and hydrogen vehicles and drone taxis. CEO Han said that eco-friendly materials will emerge as the mainstream in line with corporate ESG (environmental, social, and governance) management.

He emphasized, "After living 100 years on oil following the Industrial Revolution that utilized coal, it is time to prepare for another 100 years," adding, "We are currently in a period of energy paradigm shift and must break away from oil-based materials." Although sales have stagnated in recent years due to the COVID-19 pandemic, the company expects a rebound starting next year. They plan to prepare for future markets with steady R&D and a long-term perspective rather than focusing on short-term profits.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)