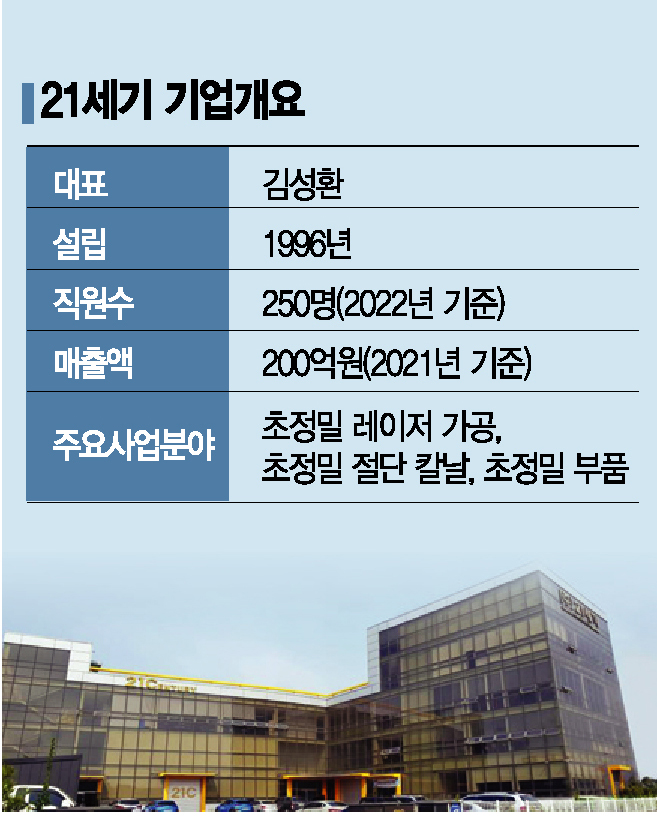

Kim Seonghwan, 21st Century Pioneer

World's First Ultra-Precision Cutting Blade Developed

4 Times Longer Lifespan Than Grinding Blades

2.5 Times Smoother Cutting Quality

Over 90% Domestic Market Share

[Asia Economy Reporter Kwak Minjae] Multilayer Ceramic Capacitors (MLCC) are called the "rice of the electronics industry." They are components embedded like grains of rice on the circuit boards of almost all electronic products such as smartphones and refrigerators, controlling electrical resistance. The size of an MLCC is only 1/250th of a grain of rice. If an imprecise blade cuts the MLCC circuit incorrectly, it can fail to control electricity, leading to product defects or fire accidents. Therefore, MLCC processing technology is demanding. Kim Seonghwan, CEO of 21st Century, a precision laser processing company, said, "As electronic products become smaller, ultra-precision laser technology for processing MLCCs is gaining attention," adding, "Our company possesses technological capabilities that surpass those of Germany and Japan in the field of ultra-precision laser application technology."

21st Century is a precision laser processing company. In 2019, it became the first in the world to develop an 'ultra-precision cutting blade' that combines femtosecond laser technology (1 femtosecond is one quadrillionth of a second) with a conventional grinding blade. Grinding blades cut by friction, generating heat at the blade tip, which shortens blade life. 21st Century minimized heat effects during blade processing by irradiating the blade tip with a laser in a new method. CEO Kim said, "When comparing grinding blades and ultra-precision cutting blades, the product lifespan differs by at least four times, and the cutting quality of our product is 2.5 times smoother." The company also developed micro-hole laser processing technology used in vacuum chucks (components used to peel and stack ultra-thin films). In the high-quality MLCC sector, where safety is critical for smartphones and electric vehicles, 21st Century holds over 90% market share for 'blades' and over 60% for 'vacuum chucks,' ranking first domestically. Last year, it recorded sales of 20 billion KRW. Its major domestic client is Samsung Electro-Mechanics.

Ultra-precision laser processing machine used for manufacturing ultra-precision cutting blades

Ultra-precision laser processing machine used for manufacturing ultra-precision cutting blades Photo by 21segi

CEO Kim graduated from a vocational high school and worked at a special cutting tool manufacturing factory before founding the current company 26 years ago with colleagues. Initially, the company mainly produced cutting tools used in automobile parts manufacturing, but considering market potential, it shifted to producing cutting tools for electronic components from the mid-2000s. Kim said, "After receiving a request from Samsung Electro-Mechanics, which mass-produces MLCCs, to drill invisible ultra-fine holes, I traveled to precision factory machinery companies in France, Germany, Japan, and others to gather ideas and conduct research, ultimately succeeding in developing the world's first micro-hole laser processing technology."

The company plans to expand its technological applications beyond ultra-precision laser cutting blades and vacuum chucks to include secondary battery thin-film cutting. It currently invests 15% of its annual sales in research and development (R&D). CEO Kim expressed his ambition, saying, "Based on ultra-precision laser application technology, we aim to increase our 2% market share in secondary battery processing and grow into a company with sales in the 50 billion KRW range within five years."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.