KCCI, Survey on Supply Chain Instability Conditions

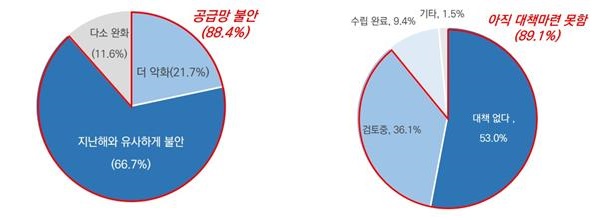

In a survey of 300 raw material import companies, responses regarding this year's supply chain outlook (left) and risk response plans

In a survey of 300 raw material import companies, responses regarding this year's supply chain outlook (left) and risk response plans

[Asia Economy Reporter Choi Dae-yeol] Nine out of ten raw material importing companies expected global supply chain instability to continue this year, following last year. However, less than 10% had concrete countermeasures in place.

According to a survey conducted on the 23rd by the Korea Chamber of Commerce and Industry targeting 300 companies importing raw materials and components from overseas, 66.7%, or two-thirds, anticipated instability similar to last year. Additionally, 21.7% expected the situation to worsen. In total, 88.4% of respondents believed that instability would persist this year, while 11.6% expected it to ease.

The main reason cited for anticipating global supply chain instability was the ongoing COVID-19 pandemic (57.0%). Other factors included the US-China hegemonic competition (23.3%) and increased demand due to global economic recovery (12.4%).

The shelves at Walmart, the largest retailer in the United States, located in Teterboro, New Jersey, are empty. In the U.S., supply chain disruptions are worsening due to the inability to deploy distribution personnel to the field promptly amid the spread of COVID-19.

The shelves at Walmart, the largest retailer in the United States, located in Teterboro, New Jersey, are empty. In the U.S., supply chain disruptions are worsening due to the inability to deploy distribution personnel to the field promptly amid the spread of COVID-19. Despite the ongoing instability, preparations were insufficient. Only 9.4% of companies responded that they had established countermeasures. More than half, 53.0%, said they had no plans, and 36.1% were still reviewing options. Some companies that had taken partial measures reported diversifying supply sources or increasing inventory. Others mentioned increasing domestic procurement or substituting materials.

Among the companies surveyed, about two-thirds reported having actually suffered damage due to last year’s supply chain instability. Many experienced production disruptions caused by delayed raw material procurement, and many also reported increased costs due to rising prices.

Jeon In-sik, head of the Industrial Policy Team at the Korea Chamber of Commerce and Industry, stated, "During a period of rapid industrial paradigm shifts such as digital transformation and carbon neutrality, the pandemic and hegemonic competition overlap, making global supply chain uncertainty inevitable for the time being. The government and companies must jointly establish a supply chain monitoring system and diversify supply sources."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)