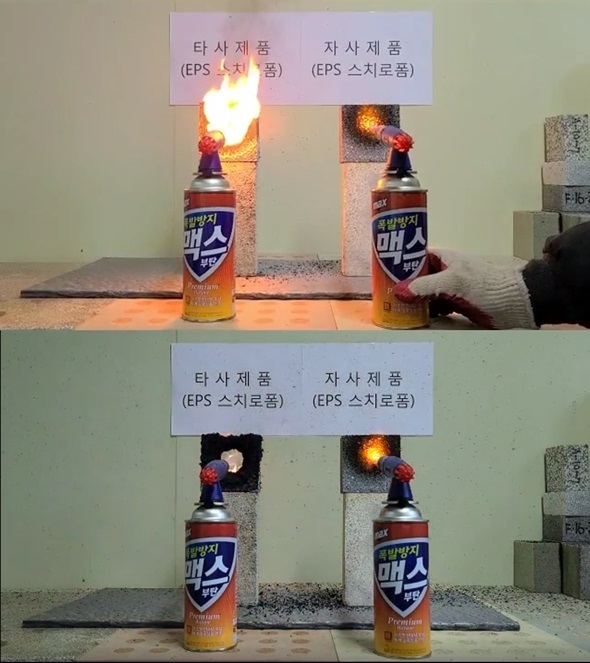

Comparison test scene between other company's EPS Styrofoam and MSR Tech products. [Photo by MSR Tech].

Comparison test scene between other company's EPS Styrofoam and MSR Tech products. [Photo by MSR Tech].

[Asia Economy Reporter Kim Jong-hwa] Amid a series of fires spreading in logistics centers due to combustible insulation materials, a styrofoam (EPS) insulation technology that ensures both safety and environmental friendliness has been developed for the first time in Korea.

Domestic eco-friendly insulation company MSR Tech Co., Ltd. announced on the 20th that it has developed a semi-noncombustible EPS insulation material called ZTD (Zero to Diamond). ZTD stands for 'production of high value-added products using waste' and is notable for applying an eco-friendly, high-efficiency manufacturing process that mixes and produces raw materials using post-consumer styrofoam.

ZTD significantly improves non-combustibility compared to existing insulation materials and complies with the revised Building Act, which strengthens fire safety standards. According to the revised "Standards for Flame Retardancy of Building Finishing Materials and Fire Spread Prevention Structures" enacted in March last year, from the 23rd of last month, only products that secure semi-noncombustibility even in the insulation core material can be used.

Insulation materials are broadly divided into organic and inorganic types depending on the presence of carbon (C). ZTD has secured excellent performance and price competitiveness even compared to inorganic insulation materials, which are fire-resistant but expensive.

In particular, through styrofoam collection and raw material utilization, ZTD contributes to ▲carbon dioxide (CO2) reduction ▲reduction of three existing EPS processes ▲cost savings, enabling participation in Korea's ESG management and carbon neutrality (Net-Zero) efforts. ZTD maximizes cost reduction and additional income by utilizing not only foamed styrofoam but also leftover styrofoam after cutting at the raw material input stage. Meanwhile, EPS power consumption decreases by 80% compared to existing processes because foaming and drying processes are unnecessary.

Kim Myung-min, director of MSR Tech, said, "We have secured insulation, non-combustibility, ease of construction, and price competitiveness," adding, "There is also abundant potential for overseas expansion, focusing on North America, Europe, and India."

He also emphasized, "As a result of conducting semi-noncombustibility performance tests independently, our product showed a visibly distinguishable difference compared to leading domestic products," and "It also demonstrated superior performance as a sandwich panel core material."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.