Extraction of Syngas from Landfill Gas... Hydrogen Purification Technology Also Under Development

Demonstration to Conclude in Second Half of Next Year... "Extracting 10,000 Tons of Hydrogen from Daegu Landfill"

Founded by KAIST PhD Graduate... Global 'Big 4' Equipment Companies Are Clients

150 Billion KRW Series C Funding Planned for This Year’s Second Half... "Discussions with Energy Companies Ongoing"

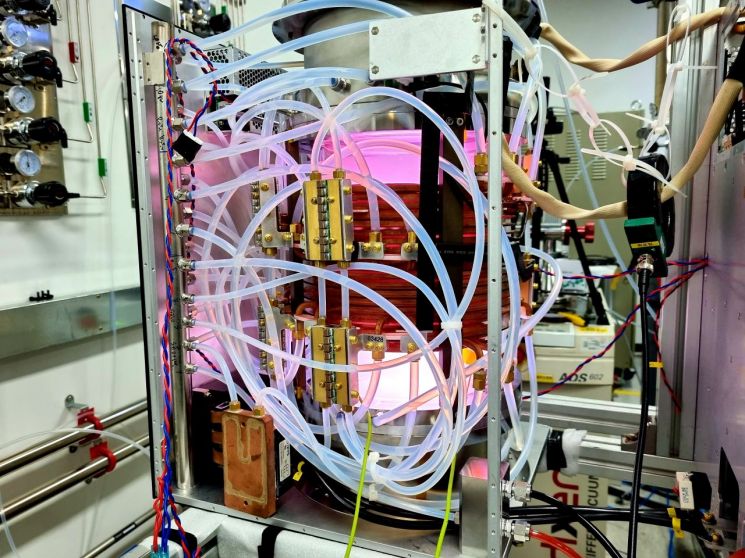

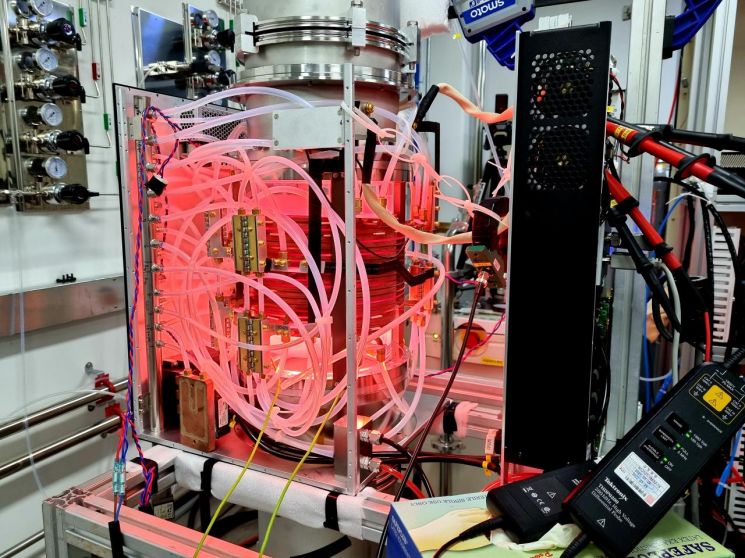

Plasma equipment under development at the Intocore Technology Research Institute located in Daejeon, Chungnam. The color inside the pipes changes depending on the chemical substances.

Plasma equipment under development at the Intocore Technology Research Institute located in Daejeon, Chungnam. The color inside the pipes changes depending on the chemical substances. Photo by Joonhyung Lee

[Daejeon=Asia Economy Reporter Lee Junhyung] Landfills are a headache for local governments. The heaps of garbage pouring in by tens of tons daily emit a significant amount of landfill gas during decomposition underground. Half of the landfill gas consists of carbon dioxide (CO2), directly linked to local governments' greenhouse gas emissions. The other half is composed of combustible methane, posing not only accident risks but also odor problems. Some local governments capture landfill gas and sell it to Korea Electric Power Corporation and others. However, landfill gas mixed with impurities such as CO2 is classified as low-grade quality, resulting in poor profitability.

IntoCore Technology is a company developing technology to extract renewable energy such as hydrogen from landfill gas. They have already secured technology to convert landfill gas into synthesis gas. Synthesis gas is a mixed gas mainly composed of carbon monoxide (CO) and hydrogen (H2). It can be refined into various fuels such as methanol. Last year, they successfully completed a demonstration study extracting high-purity methanol after converting landfill gas into synthesis gas. Um Sehoon, CEO of IntoCore Technology, explained, "Synthesis gas can be refined into hydrogen, a future energy source," adding, "Since the second half of 2020, we have embarked on a demonstration study to extract hydrogen from landfill gas."

Demonstration in Daegu by Next Year

The demonstration partner is Daegu City. The company established a methanol production plant at the landfill site located in Bangcheon-ri, Daegu. Currently, this plant produces about 50kg of methanol daily using landfill gas from the Bangcheon-ri landfill as raw material. The company plans to complete the hydrogen refining demonstration study by the second half of next year and then transform the existing methanol production plant into a hydrogen production plant. Once hydrogen production within the landfill site is in full swing, about 10,000 tons of hydrogen can be extracted annually from the approximately 1,053,000㎡ (about 318,533 pyeong) Bangcheon-ri landfill. Daegu City is considering developing the public bus garage near the Bangcheon-ri landfill into hydrogen refueling infrastructure.

Hydrogen refining technology is rare not only in Korea but also globally. This means it requires very advanced technology. The reason a company with about 50 employees could take on such a challenge lies in their plasma technology. Plasma is the fourth state of matter, neither solid, liquid, nor gas. The company's plasma technology was the secret to extracting only high-purity methanol from landfill gas. The core of the hydrogen refining technology currently under development is also plasma.

Plasma equipment under development at the Intocore Technology Research Institute located in Daejeon, Chungnam. The color inside the pipes changes depending on the chemical substances.

Plasma equipment under development at the Intocore Technology Research Institute located in Daejeon, Chungnam. The color inside the pipes changes depending on the chemical substances. Photo by Lee Junhyung

Global Semiconductor Equipment Companies Also ‘Love Call’

The company's original main business area is semiconductor processing. Plasma is considered a core technology in the semiconductor industry. It is used directly or indirectly in 50-60% of the entire semiconductor process. However, few domestic companies possess proper plasma technology. IntoCore Technology was recognized for its technological prowess, being selected as the first company in the Semiconductor Growth Fund established by Samsung Electronics, SK Hynix, and others in 2017. They have also conducted technical cooperation with KAIST Professor Jang Hongyoung, a leading plasma authority in Korea, as well as the Korea Research Institute of Chemical Technology and the Korea Institute of Energy Research. CEO Um himself is a scientist who earned a Ph.D. in plasma physics from KAIST. He stated, "We hold over 40 patents related to plasma," and "40% of our employees are plasma researchers with master's and doctoral degrees from KAIST and POSTECH."

In the semiconductor industry, the company has already established itself as a "small but strong" enterprise. Leading domestic semiconductor equipment companies such as Jusung Engineering, Wonik IPS, and SEMES are clients. Global 'Big 4' semiconductor equipment companies like Lam Research in the U.S. and Tokyo Electron (TEL) in Japan also use IntoCore Technology's products. CEO Um said, "Global semiconductor equipment companies have expressed their intention to participate as strategic investors (SI) in the 15 billion KRW Series C investment planned for the second half of this year," adding, "The petrochemical industry is also paying attention to plasma technology, and we are conducting various discussions with energy companies."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.