KIST-KAIST Joint Research... Utilizing Ultrafine Printing Technology

[Asia Economy Reporter Kim Bong-su] Hydrogen fuel cells, which generate electrical energy using hydrogen as fuel, play a role similar to an engine in hydrogen electric vehicles. However, there is a problem that the carbon particles used to support the platinum catalyst, a core component of the fuel cell, are easily corroded, resulting in a short lifespan of the fuel cell. Corroded fuel cells need to be replaced, and the replacement cost, which can range from tens of millions to hundreds of millions of won, is inevitably a burden for vehicle owners.

Domestic researchers have developed a technology that can dramatically extend the lifespan of hydrogen fuel cells by solving this problem. On the 8th, the Korea Institute of Science and Technology (KIST) announced that Dr. Kim Jin-young of the Hydrogen and Fuel Cell Research Center and Dr. Kim Jong-min of the Materials Structure Control Research Center, in collaboration with the Korea Advanced Institute of Science and Technology (KAIST), developed a new form of platinum nanostructured electrode that does not use carbon?the cause of fuel cell corrosion?by utilizing a simple 20 nm-scale ultra-fine printing technology similar to stamping.

Platinum used as a catalyst in hydrogen fuel cells tends to clump together when at the nanometer scale, making it unstable and unusable as a catalyst material on its own. Therefore, the currently commercialized catalyst stabilizes 2?5 nm platinum nanoparticles attached to carbon particles. However, carbon particles are lost due to corrosion during the repeated operation of the fuel cell, failing to support the platinum, which causes the fuel cell’s performance to continuously decline. Additionally, the electrode thickness is several micrometers and structurally complex, resulting in poor fuel cell efficiency.

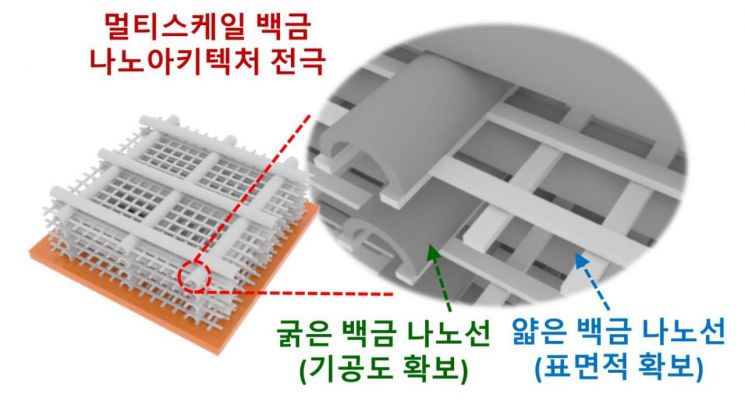

The research team developed an ultra-fine process that repeatedly applies a simple printing process like stamping to stack stable 20 nm-scale platinum structures, creating a stable platinum catalyst without using the carbon particles that are fatal to the lifespan of hydrogen fuel cells. The electrode developed through this process resembles a steel-frame building, with wide passages between structures that facilitate the movement of oxygen, hydrogen, and water inside the fuel cell, and it can be made less than one-tenth the thickness of existing electrodes. As a result, electrodes can be produced using only platinum without carbon particles, and when using these electrodes, durability improved more than threefold compared to existing commercial catalyst electrodes, while fuel cell output increased by about 27%.

Dr. Kim Jin-young said, “The catalyst developed through ultra-fine printing technology can dramatically improve the durability and performance of electrodes, securing the economic feasibility of hydrogen fuel cells,” and added, “We expect its application not only in fuel cells but also in various electrochemical fields such as catalysts, sensors, and batteries.”

The results of this research were published in the latest issue of the international scientific journal ‘Science Advances’ (IF: 14.136, JCR top 6.164%).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.