The government and private companies have succeeded in developing a technology that shortens the design period of the giant drill called 'Cutter head' used for drilling urban tunnels from the existing more than one month to within three days.

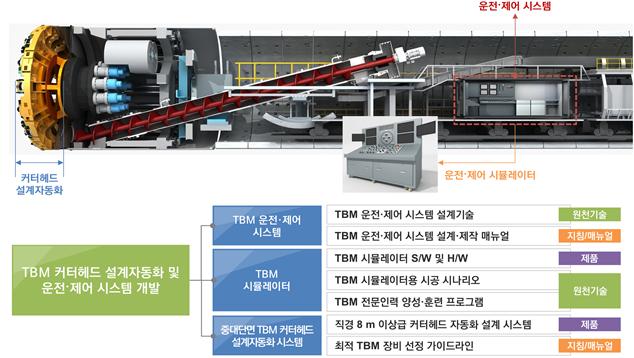

On the 20th, the Ministry of Land, Infrastructure and Transport announced that it has developed the world's first 'TBM (Tunnel Boring Machine) Cutter Head Design Automation System' and also succeeded in domestic production of the core technology, the 'TBM equipment operation and control system.'

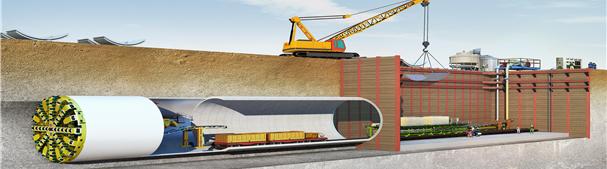

TBM is an eco-friendly and economical tunneling method used for urban tunnels, underwater tunnels, and long mountain tunnels. Unlike the past blasting tunneling method, it is an advanced construction machine that mechanically excavates the entire tunnel cross-section, minimizing noise and vibration and maximizing construction efficiency.

The cutter head is a giant drill used to bore tunnels and is located at the front of the excavator.

The technology developed this time is the result of participation by four private companies including the Korea Institute of Civil Engineering and Building Technology and EM Korea in the Ministry of Land, Infrastructure and Transport's research and development (R&D) project, with a total investment of 9.4 billion KRW from 2017 to this year.

Currently, six countries including Germany, the United States, Japan, China, Australia, and Canada, which possess TBM design and manufacturing technology, strictly keep TBM manufacturing and operation technologies confidential, making it practically difficult to secure original technology.

Conceptual Diagram of TBM Applied Excavation Site (Photo by Ministry of Land, Infrastructure and Transport)

Conceptual Diagram of TBM Applied Excavation Site (Photo by Ministry of Land, Infrastructure and Transport)

The world's first developed 'TBM Cutter Head Design Automation System' is an advanced technology that automatically designs a suitable cutter head by inputting various ground conditions into a 3D program, replacing the previously manual cutter head design process.

The cutter head design period, which currently takes more than a month on average, can be completed within three days through design automation technology.

The 'TBM equipment operation and control system' developed with domestic technology is a core technology for operating TBM that automatically controls and operates cutter head rotation speed and excavation direction, a technology possessed only by some advanced countries.

Recently, worldwide, the use of mechanical excavation methods utilizing TBM is increasing to minimize noise and vibration damage during tunnel excavation work and to create a safe working environment.

The global market size for TBM utilization is expected to grow significantly every year, indicating high utility of the technology development. The global TBM usage market grew fivefold from about 11 trillion KRW in 2010 to about 55 trillion KRW last year.

Lee Sang-joo, Director of Technology Safety Policy at the Ministry of Land, Infrastructure and Transport, said, "The development of TBM cutter head design automation and operation and control systems is a great achievement that shows the potential for Korea's construction technology to lead the global market," adding, "Through technology transfer and commercialization to domestic small and medium enterprises, we expect active expansion not only in the domestic market but also in overseas markets."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.