Solarplex Develops 2nd Generation Solar Cell with Enhanced Flexibility

Lightweight and Bendable for Anywhere Installation... No Function Loss Even When Cut

ESG Trend Sparks Love Calls Everywhere... Targeting Factories and Roads

[Asan, Chungnam=Asia Economy Reporter Lee Junhyung] Most solar cells available on the market are first-generation wafer-based products. Wafers are thin substrates made of silicon or other materials, involving complex processes and relatively high manufacturing costs. They convert 18-20% of sunlight into electricity, making them the most efficient solar cells currently commercialized. However, they lack flexibility and have weak durability. The first generation improved durability by adding tempered glass on top of the wafer, but safety issues can arise from glass shards if broken.

The ‘CIGS (Copper-Indium-Gallium-Selenium) thin-film solar cell’ was developed as an alternative to the first generation. It is made by combining inorganic compounds with high light absorption rates. Although its power conversion efficiency is about 2-3 percentage points lower than the first generation, its thinness and light weight make it a promising second-generation product to replace conventional solar cells.

‘Flexible Solar Cells’ Reduce Weight and Thickness... Increasing Versatility

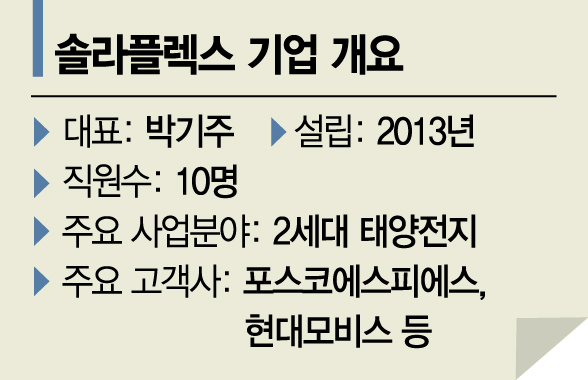

Solarplex, a solar cell manufacturer, has taken a step further by developing ‘flexible solar cells.’ The company enhanced the flexibility of CIGS solar cells to make them bendable. Park Giju, CEO of Solarplex, explained, "Thanks to the flexible material, unlike the first generation which breaks at wind speeds of 30m/s, our cells withstand strong winds of up to 60m/s," adding, "Their high flexibility and light weight make them optimal for Building-Integrated Photovoltaics (BIPV)."

The secret lies in the stainless steel substrate. Solarplex’s solar cells are based not on wafers but on thin films made by rolling stainless steel. The thickness is 4 microns, about 1/47th of the first generation’s 188 microns. The weight has been reduced from 18kg per square meter to 3.5kg. Combined with the inherent flexibility of stainless steel, the solar cells can be bent freely.

With drastically reduced weight and thickness, the applications are endless. Conventional solar cells were limited in installation locations due to their considerable weight. The first generation was mainly installed on land or building roofs, but land required large areas relative to power output, and lightweight roofs such as those made of prefabricated panels could not support them. Additionally, installing on buildings required drilling holes about 60cm in size and fixing anchors at each corner of the solar cells, resulting in installation costs of approximately 1 million KRW per kW for roofs and 4 million KRW for walls.

The thickness of the second-generation solar cells produced by Solarplex is 4 microns, which is only about 1/47th of the first generation (188 microns).

The thickness of the second-generation solar cells produced by Solarplex is 4 microns, which is only about 1/47th of the first generation (188 microns). [Photo by Joonhyung Lee]

In contrast, Solarplex’s solar cells have virtually zero installation costs. They feature a highly adhesive double-sided tape on the back, allowing them to be attached anywhere?glass, concrete, panels?without additional fixtures. Unlike the first generation, which loses functionality if standardized wafers are damaged, these cells can be cut to any desired size. This enables easy use of renewable energy in ordinary homes by cutting and attaching solar cells to veranda windows, for example. They can also be perforated, making them suitable for ginseng cultivation facilities that require about 10-15% sunlight.

Resolving Safety Issues Like Shards... From Aging Factories to Smart Farms

BIPV is a field with both high applicability and growth potential. Solarplex’s solar cells can be installed anywhere on buildings?roofs, exterior walls, windows?regardless of building materials. Being adhesive, there is no concern about anchors weakening due to rain or wind, solving the vulnerability to natural disasters like typhoons seen in the first generation. CEO Park said, "Conventional solar cells posed safety issues when broken by typhoons, as shards could cause accidents," adding, "We can apply colors with high light absorption to the solar cells, and by perforating holes, they can be used in smart farms."

Solar cells being developed and produced at the Solarplex headquarters located in Asan, Chungnam.

Solar cells being developed and produced at the Solarplex headquarters located in Asan, Chungnam. [Photo by Joonhyung Lee]

Driven by the ESG (Environmental, Social, and Governance) trend, Solarplex is receiving numerous inquiries, especially from manufacturers. The light weight of Solarplex’s solar cells makes them easy to install even on aging factory slate roofs. The company is negotiating a pilot installation of 2MW solar cells on the roof of a large corporation’s factory located in Pohang, Gyeongbuk, in the second half of this year. CEO Park explained that after verification, the installation scale could be expanded to 40MW next year. They are also discussing installing 3.54MW of solar cells on parts of another large corporation’s factory.

The company is also discussing solar road pilot projects with several local governments. CEO Park said, "We have received proposals from large construction companies to jointly develop technology," adding, "We are also working on standardizing solar cell modules to meet the demand in the building materials market."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.