Korea Institute of Machinery and Materials Develops Video Diagnostic Technology Using Machine Learning

[Asia Economy Reporter Kim Bong-su] A technology that can significantly improve the performance of imaging medical diagnostic equipment such as MRI through big data deep learning has been developed.

The Korea Institute of Machinery and Materials announced on the 9th that it has developed a technology that combines machine learning techniques from mechanical equipment with imaging medical diagnostic devices to enhance both the speed and accuracy of disease diagnosis.

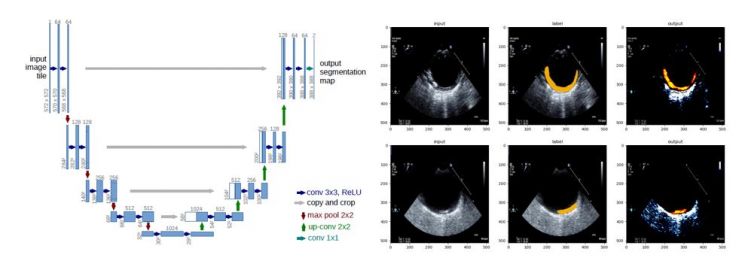

The research team led by Director Park Jong-won of the Reliability Evaluation Research Lab at KIMM applied big data deep learning technology, previously used for reliability diagnosis of mechanical parts and equipment, to ultrasound imaging diagnostic devices, developing an 'imaging diagnostic technology utilizing machine learning.' Using GPUs (graphics processing units), they succeeded in achieving diagnostic accuracy at the level of 80%. The development of a deep learning model capable of classifying aortic plaques (foreign substance masses) by condition and measuring plaque thickness was a novel attempt.

The research team applied various machine learning techniques, including Autoencoder and U-net models, to the ultrasound imaging discrimination of the aortic wall. By analyzing the aortic wall through ultrasound imaging, it is possible to check the condition of aortic atherosclerotic plaques, which are emerging as a cause of stroke.

The team plans to improve the deep learning model to enhance the accuracy of aortic plaque analysis. In the future, they aim to expand the technology to be used for fault diagnosis by utilizing image data of failure phenomena in parts within the establishment of a virtual engineering platform for future transportation equipment parts manufacturing and the Materials-Parts Convergence Alliance (mechanical and automotive fields) project.

Director Park Jong-won stated, “Until now, users needed complex data interpretation skills to judge faults and lifespans of mechanical parts and equipment, but now it has become easily accessible by utilizing various open sources,” adding, “Imaging diagnostic technology using machine learning is expected to be applied in various fields, such as developing models for interpreting various diseases and predicting the lifespan of parts and equipment.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)