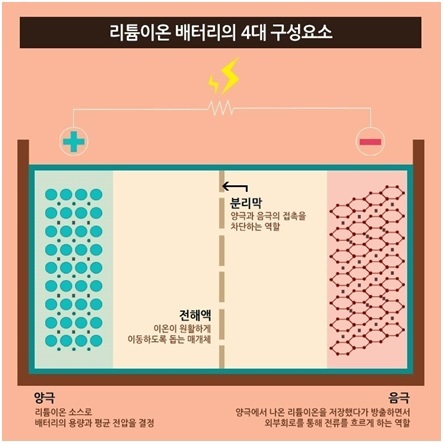

[Asia Economy Reporter Hwang Yoon-joo] The component that acts as the engine of an electric vehicle is the secondary battery (battery). The batteries currently in use are mainly lithium-ion batteries, which consist of four key materials: cathode, anode, electrolyte, and separator.

The cathode of a lithium-ion battery is where lithium, which generates electricity, is densely packed. In other words, it can be considered the "home" of lithium. The cathode is composed of a combination of lithium and metal components, with representative metals being NCA (Nickel/Cobalt/Aluminum) or NCM (Nickel/Cobalt/Manganese).

The anode can be thought of as the "home" where lithium ions (Li+) enter after lithium in the cathode separates into lithium ions (Li+) and electrons (e-) due to external influences. Graphite is mainly used for the anode.

The electrolyte is a liquid medium that allows lithium ions (Li+) to move smoothly from the cathode to the anode. The separator is a kind of membrane that physically prevents the cathode and anode from coming into contact. If the cathode and anode meet, heat is generated, which can cause safety issues.

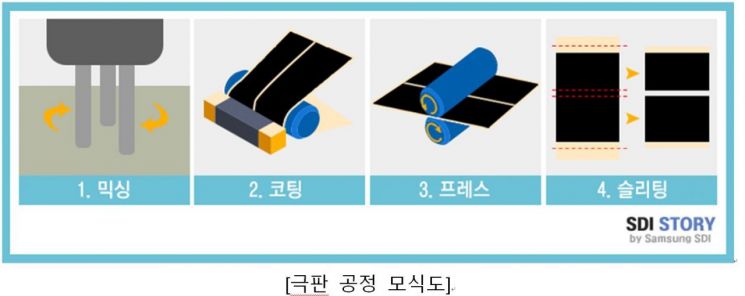

◆ Making Cathode and Anode... Electrode Plate Process

The battery manufacturing process is broadly divided into three stages: electrode plate process, assembly process, and formation process.

The electrode plate process is the fundamental step in battery production. As the name suggests, this process involves making the cathode and anode, which are two of the four main components of the battery discussed earlier.

The electrode plate process can be further divided into four steps. The first step is mixing. Mixing involves adding conductive materials (conductive agents) and binders to the active material and blending them to create a mixture (compound).

After mixing, coating is performed. Coating is the step where the active material mixture (compound) is applied onto a metal plate. Aluminum plates are used for the cathode, and copper plates are used for the anode. Once the mixture is evenly applied on the metal plate through coating, pressing (compression) is done to ensure the mixture adheres well and does not fall off. Then, the electrode plates are cut to size in the slitting step, and moisture and other impurities are removed to complete the electrode plate process.

◆ Assembly Process to Form Battery Shape

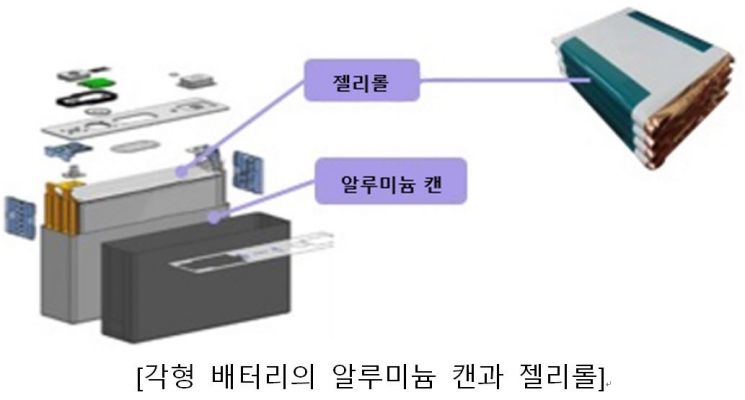

In the assembly process, a separator is sequentially stacked between the cathode and anode plates, followed by winding, where the layers are rolled up, or stacking, where the plates are cut and neatly stacked, to create an intermediate battery form called a "jelly roll."

The jelly roll produced in this way is placed inside an aluminum can for cylindrical and prismatic types, or wrapped in a pouch for pouch-type batteries. The pouch is then sealed by welding or bonding to prevent leakage, and electrolyte is injected to complete the assembly process.

Notably, Samsung SDI, one of the top three battery companies in Korea, operates its assembly process in an automated manner. If any issues arise that deviate from preset values at each stage, an alert sounds within the manufacturing line, and defective cells are automatically sorted out to prevent them from proceeding to the next stage. This system ensures that only batteries with perfect performance and quality move on to subsequent processes.

After completing the assembly process, the battery externally resembles the form we use, but it is not yet electrically activated. The process of supplying electrical energy to activate the battery is called the formation process. The first step in the formation process is aging, where the battery is stored for a set period under controlled temperature and humidity. This step allows the electrolyte inside the battery to distribute evenly, optimizing ion movement.

Samsung SDI stated, "All batteries produced at Samsung SDI are assigned individual barcodes, and thousands of inspection items are checked during the manufacturing process using advanced equipment such as X-ray and vision inspection. We also manage the entire manufacturing history and conduct full inspections to ensure that only defect-free batteries are shipped to the field."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.