Korea Institute of Energy Research Develops High-Value Utilization Technology for Bacterial Cellulose

Maximizing Fuel Cell Catalyst Durability with Porous Graphene Nano-Sandwich Structure

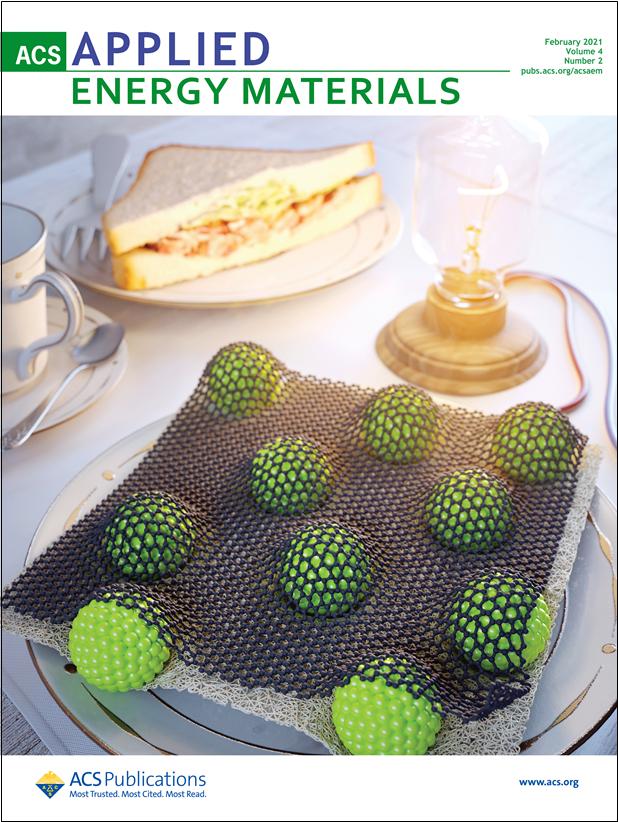

ACS Applied Energy Materials Cover Paper (02.22): A sandwich-type fuel cell electrode with a graphene protective layer (black mesh structure) applied on the surface of platinum nano-catalysts (light green particles) embedded in bacterial cellulose surface (gray mesh structure). The synthesized ultrathin electrode demonstrated excellent performance and long-term stability in catalyst performance evaluation for fuel cells. Provided by Korea Institute of Energy Research

ACS Applied Energy Materials Cover Paper (02.22): A sandwich-type fuel cell electrode with a graphene protective layer (black mesh structure) applied on the surface of platinum nano-catalysts (light green particles) embedded in bacterial cellulose surface (gray mesh structure). The synthesized ultrathin electrode demonstrated excellent performance and long-term stability in catalyst performance evaluation for fuel cells. Provided by Korea Institute of Energy Research

[Asia Economy Reporter Kim Bong-su] A domestic research team has developed a new catalyst structure combining nanocellulose produced by bacteria, platinum nanoparticles, and porous graphene in a layered sandwich structure to improve the performance and durability of platinum catalysts used in fuel cells.

The Korea Institute of Energy Research announced on the 10th that Dr. Kim Hee-yeon’s research team at the Energy Materials Laboratory developed a technology to produce carbon with excellent surface area and electrical conductivity by heat-treating bacterial cellulose, a type of biomass, at a relatively low temperature above 600°C.

By loading platinum nanoparticles on the surface of the developed carbonized material and applying a porous graphene protective layer on the platinum particle surface, the team succeeded in synthesizing a fuel cell catalyst with long-term stability improved by more than 220% compared to existing commercial catalysts through the new nano-sandwich structure.

Cellulose material is one of the natural polymers, environmentally friendly, renewable, and cheaper than conventional composites. Cellulose produced through bacterial cultivation exhibits characteristics such as high crystallinity, moisture absorption rate, and mechanical strength, and is composed of pure cellulose, eliminating the need for purification processes. Particularly, due to its excellent biocompatibility, it has been used in fields such as medical, cosmetics, and food, but high value-added applications as an energy material are extremely rare.

With greenhouse gas reduction and strengthened environmental regulations, hydrogen plays a key role in the Green New Deal and carbon neutrality transition. Fuel cells utilizing hydrogen energy are expanding into various sectors such as transportation and power generation, leading the growth of the hydrogen society.

Fuel cells are high-efficiency power generation systems that produce electricity through electrochemical reactions between hydrogen and oxygen. To reduce the price per kW, active development is underway for domestic production of systems such as stacks, hydrogen extractors, and inverters, as well as for alternatives or efficient use of platinum catalysts.

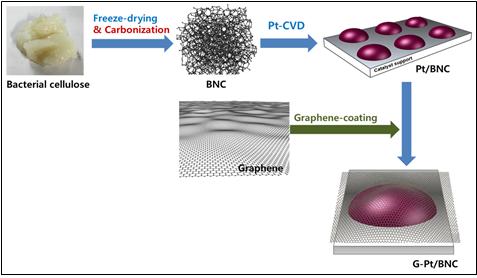

Synthesis method of platinum catalyst with nano-sandwich structure for polymer electrolyte fuel cells. Provided by Korea Institute of Energy Research

Synthesis method of platinum catalyst with nano-sandwich structure for polymer electrolyte fuel cells. Provided by Korea Institute of Energy Research

Although platinum catalysts used in polymer electrolyte fuel cells have excellent performance, their high cost makes reducing manufacturing costs while improving long-term durability essential. Researchers study methods to reduce catalyst size to achieve a wide active area with a small amount of raw material. However, as catalyst particle size decreases, particle instability increases, making them more prone to dissolution or ripening, which leads to deactivation.

To overcome these drawbacks of existing fuel cell catalysts, the research team proposed a new nano-sandwich structured catalyst. Specifically, they synthesized a new nano-sandwich catalyst structure by using carbonized bacterial cellulose as a catalyst support, highly dispersing platinum nanoparticles on its surface via chemical vapor deposition, and applying a porous graphene cover.

The nano-sandwich platinum catalyst showed durability improved by more than 220% compared to commercial catalysts due to the excellent electrical and chemical resistance properties of the cellulose support and the graphene cover’s prevention of catalyst particle corrosion, detachment, and aggregation.

The nano-sandwich catalyst developed by the research team is useful for manufacturing ultra-thin electrodes due to the ultra-thin structure of carbonized bacterial cellulose and can be effectively applied to various electrochemical reactions such as electrochemical hydrogen production. Porous nanocarbon derived from bacterial cellulose can be synthesized at significantly lower temperatures than conventional carbon materials like carbon black and activated carbon, making it expected to effectively replace existing carbon materials.

Dr. Kim Hee-yeon, principal researcher at the Energy Materials Laboratory, said, “Since the mid-2000s, we have been researching technologies to synthesize various cellulose carbons and utilize them as catalyst supports and fuel cell electrodes through the development of high value-added utilization technologies for natural cellulose materials. This study is meaningful in that it created synergy by combining biomass high value-added utilization technology with semiconductor process-based catalyst manufacturing technology.”

This result was published as the cover paper in the journal ‘ACS Applied Energy Materials’ issued by the American Chemical Society on the 22nd of last month.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.