Supporting Automation through Digital Transformation and Collaborative Robot Adoption in Production Sites

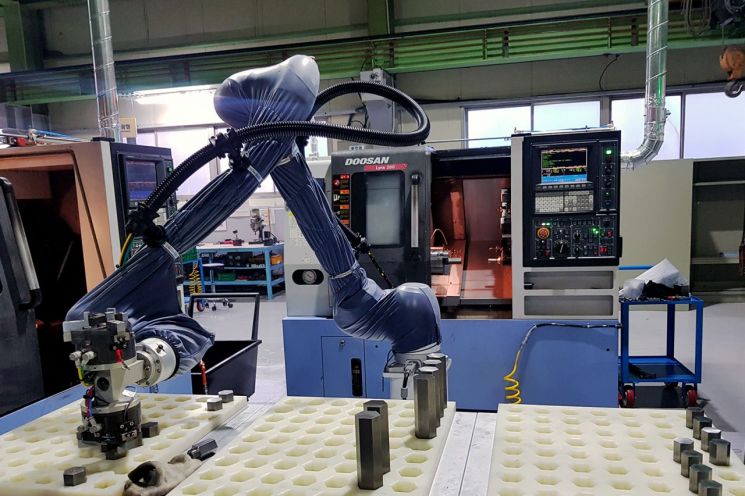

Doosan Corporation's collaborative robots, introduced to build smart factories for partner companies, are performing tasks on the production floor.

Doosan Corporation's collaborative robots, introduced to build smart factories for partner companies, are performing tasks on the production floor.[Photo by Doosan Corporation]

[Asia Economy Reporter Ki-min Lee] Doosan Corporation announced on the 24th that it will apply Manufacturing Execution Systems (MES) to 10 partner companies this year to support the digital transformation of production sites and introduce collaborative robots to assist in establishing automated production lines.

Doosan Corporation is participating in the Smart Factory Construction Project led by the Ministry of SMEs and Startups' Smart Manufacturing Innovation Promotion Group, supporting efficient production process management for partner companies by implementing MES and Product Lifecycle Management (PLM) systems.

Having supported eight partner companies last year, Doosan Corporation plans to increase the number of supported companies to 10 this year and newly support the introduction of collaborative robots. Collaborative robots can perform delicate tasks requiring human dexterity even in narrow spaces without safety fences, reducing the intensity of simple labor for workers while improving work expertise and productivity.

Partner companies expect that the introduction of collaborative robots will enable flexible deployment of workers, allowing them to actively prepare for the 52-hour workweek system, which will be fully implemented starting next year.

Choi Won-woo, CEO of Yedam Chemical, an electronic materials processing company, said, "In a situation where new investments are difficult due to the prolonged COVID-19 pandemic, we were able to build a smart factory with Doosan Corporation's support," adding, "We will enhance productivity through the introduction of new systems and create a new opportunity for growth."

Previously, partner companies supported by Doosan Corporation last year showed improvements in key production efficiency indicators such as ▲shortened manufacturing lead time ▲reduced product defect rates ▲and decreased inventory compared to before.

Yeonhap System, a forklift bearing manufacturer, introduced the Product Lifecycle Management (PLM) system transferred by Doosan Corporation last year, resulting in a 20% reduction in manufacturing lead time and a 75% decrease in product defect rates. By improving design drawing management and eliminating inefficiencies, they also achieved a 20% increase in on-time delivery rates compared to before.

Meanwhile, Doosan Corporation is also practicing win-win management through professional consulting funded by the mutual cooperation fund, overseas joint expansion support projects, and capacity-building education.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.