Quality Evaluation of Korean Hydrofluoric Acid to Begin as Early as Next Week

A Step Closer to Technological Independence for Semiconductor Hydrofluoric Acid

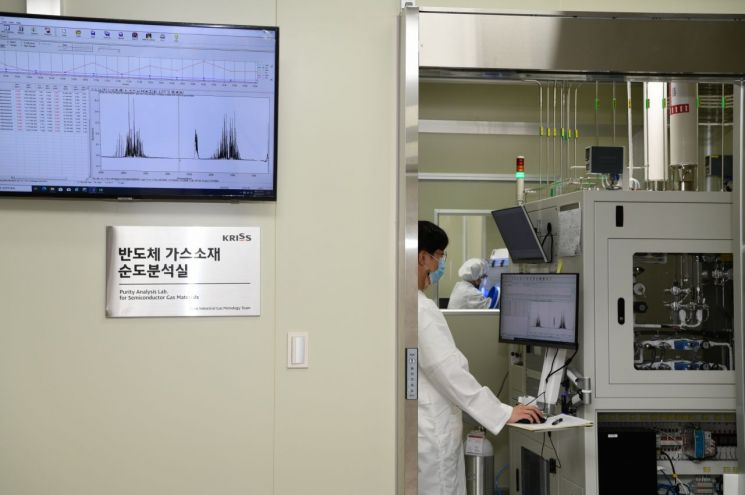

The Gas Analysis Standard Group, Industrial Toxic Gas Analysis Standard Team at the Korea Research Institute of Standards and Science is conducting quality evaluation of hydrofluoric acid.

The Gas Analysis Standard Group, Industrial Toxic Gas Analysis Standard Team at the Korea Research Institute of Standards and Science is conducting quality evaluation of hydrofluoric acid.

[Asia Economy Reporter Hwang Junho] Nationally certified quality evaluation of high-purity gases for semiconductors, such as hydrogen fluoride produced in Korea, is set to begin. With credible evaluations of domestic materials and subsequent comparative analyses, it is expected to take a step closer to technological independence from Japan. If domestic companies like Samsung Electronics and SK Hynix utilize domestic materials based on the quality evaluation results, it is anticipated that a foothold for entering the global market will also be established.

Domestic Hydrogen Fluoride to Face Testing as Early as Next Week

The Korea Research Institute of Standards and Science (KRISS) announced on the 22nd that it will begin quality evaluations of domestically produced high-purity semiconductor gas materials as early as next week. The institute started building facilities in August last year to respond to Japan's semiconductor material export restrictions. Using an emergency internal budget of 1.5 billion KRW, including 800 million KRW for analytical equipment and 700 million KRW for facility construction, the laboratory was completed.

The institute will start quality evaluations with domestic hydrogen fluoride. The quality evaluation of hydrogen fluoride is conducted by measuring impurities to determine purity. Liquid hydrogen fluoride in cylinders is vaporized to analyze the gas composition. Using gas chromatography and Fourier-transform infrared spectroscopy (FTIR), about 10 types of gaseous impurities are analyzed, and inductively coupled plasma mass spectrometry (ICP-MS) is used to analyze about 20 types of metallic impurities to determine the final purity.

Oh Sang-hyup, principal researcher of the Gas Analysis Standards Group at the institute responsible for hydrogen fluoride standard evaluation, said, "Once the quality evaluation results are out, it will be the first credible evaluation."

Korea Research Institute of Standards and Science Gas Analysis Standard Group Industrial Toxic Gas Analysis Standard Team (from left: Byungmoon Kim, Principal Engineer; Sanghyup Oh, Principal Researcher; Sunwoo Kim, Engineer)

Korea Research Institute of Standards and Science Gas Analysis Standard Group Industrial Toxic Gas Analysis Standard Team (from left: Byungmoon Kim, Principal Engineer; Sanghyup Oh, Principal Researcher; Sunwoo Kim, Engineer)

There was no way to compare the quality (purity) of domestic high-purity hydrogen fluoride. Since verification methods varied by company, a credible evaluation method for comparative analysis of purity was needed. Especially, evaluation of Japanese materials was difficult. As strategic items, and due to costs related to equipment procurement for analysis, individual companies were unable to evaluate quality.

Hydrogen fluoride is used in the cleaning and etching processes of semiconductor wafers, the semiconductor substrates. High-purity hydrogen fluoride is necessary to improve semiconductor manufacturing yield. The global market is monopolized by Japanese companies such as Showa Denko, Morita, and Stella Chemifa.

Researcher Oh explained, "Being able to evaluate quality from the product development stage can contribute to improving the quality of domestic materials."

The institute plans to develop a standard test procedure for this evaluation by the first half of next year, starting with hydrogen fluoride evaluation. It also plans to develop analytical methods for about 20 types of gas materials. They will form a consultative body with domestic companies to conduct proficiency testing as well.

Director Park Hyun-min stated, "Since the second half of 2019, we have operated the ‘Japan Export Regulation Active Response Committee’ to support reliability evaluation technologies for materials, parts, and equipment," adding, "Based on the world's top-level measurement technology possessed by the institute, we will contribute to enhancing the national competitiveness of related industries."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.