GS EPS Dangjin Power Plant and Smart System Collaboration

A field worker at the GS EPS plant is checking equipment information on a tablet. When the QR code attached to each device is scanned with the tablet, related information such as maintenance history can be automatically viewed.

A field worker at the GS EPS plant is checking equipment information on a tablet. When the QR code attached to each device is scanned with the tablet, related information such as maintenance history can be automatically viewed. [Photo by LG Uplus]

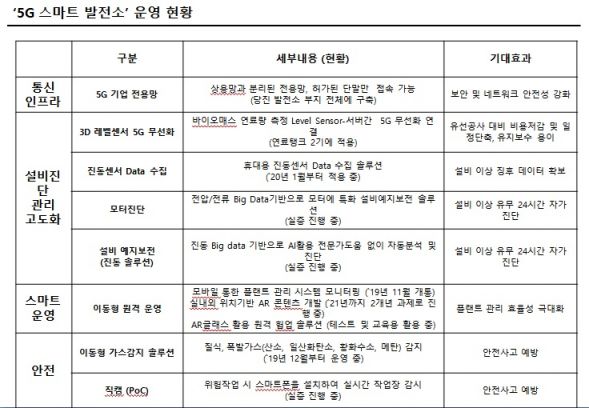

[Dangjin=Asia Economy Reporter Kim Heung-soon] In Dangjin City, Chungnam Province, there is GS Group’s power generation company GS EPS. Operating five power plants on a site of approximately 400,000㎡ (about 120,000 pyeong), it produces and supplies electricity using natural gas. Power plants are representative utility industries that supply electricity and gas necessary for daily life and industry. This large-scale facility is recently transforming into a smart power plant by integrating 5th generation (5G) mobile communication technology. LG Uplus is supporting the establishment of a smart system at the power plant based on core technologies of the 4th Industrial Revolution such as 5G, Internet of Things (IoT), and Artificial Intelligence (AI).

24-Hour 'Automatic Monitoring' of Fuel Tanks with 5G and IoT

Evolving into a 'Cable-Free Power Plant'

Remote Monitoring of Equipment Data on Smartphone Screens

Last month, LG Uplus completed the construction of a 5G enterprise private network at the GS EPS Dangjin Power Plant. This is the first case in Korea where a 5G network was applied to power plant facilities. On site, engineers easily check equipment data, operation manuals, and necessary parts on their smartphones by using QR codes attached to large machines. This is possible because large-capacity data containing parts information for all equipment is connected to smartphones through the LG Uplus private network with enhanced security.

A GS EPS official said, "Previously, to check equipment-related information, we had to work at high structures and then come down to the ground or move to spaces where blueprints were stored, which was cumbersome. Now, we can immediately grasp the desired information with smart devices, greatly reducing the time and inconvenience involved in work processes."

At the GS EPS central control room, the remaining natural resource energy in fuel tanks can be remotely checked. Each fuel tank is equipped with a 5G and IoT-based '3D level sensor' that three-dimensionally visualizes the actual fuel status inside the tank. All installations are wireless. LG Uplus explained, "Compared to connecting each fuel tank and control system with wired connections, construction and maintenance costs can be reduced by more than 70%."

Preparing for Safety Accidents with AI and Big Data Predictive Analysis Solutions

Considering Introduction of Equipment Inspection and Parts Transport Robots

The power plant consists of more than 1.5 million various parts and sensors per unit. The introduction of a smart management system is a measure to reduce the hassle of engineers inspecting each item individually and to improve the efficiency of power plant management. GS EPS has established a five-year plan for 'Smart Power Plant Evolution' to collect big data necessary for power plant equipment and operations in one place and build infrastructure to manage it from this year through 2024.

A GS EPS official said, "Until now, we found the equipment with problems and detected and supplemented only that part. Going forward, our goal is predictive maintenance that anticipates potential problems and performs appropriate maintenance and repairs."

LG Uplus also plans to support this based on the latest technologies. First, since December last year, it has been operating a mobile explosive gas detection solution, and in January this year, it introduced a portable vibration sensor data collection solution to diagnose abnormal signs in equipment. Subsequently, it plans to use AI technology to check equipment abnormalities 24 hours a day.

LG Uplus and GS EPS jointly stated, "The goal of a smart power plant is to provide operators with necessary data quickly and accurately through 4th Industrial Revolution technologies and to achieve economical operation without the need for additional supplementation. It is absolutely not aimed at unmanned operation where technology replaces human work."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.