Hanil Electric Builds New Factory After 56 Years

Maintains 70% Domestic Production and Employs 1,000 While Others Move to China

The Hanil Electric factory, established in Bucheon in 1964, has been newly rebuilt on the same site after 56 years and is about to hold its completion ceremony. Photo by Hanil Electric

The Hanil Electric factory, established in Bucheon in 1964, has been newly rebuilt on the same site after 56 years and is about to hold its completion ceremony. Photo by Hanil Electric

[Asia Economy Reporter Kim Heeyoon] “Don’t worry about water~” Hanil Electric, a leading electrical company that developed the nation’s first automatic pump, is preparing for a new leap forward with the completion of its new Bucheon factory (Shin Hanil Electric Bucheon Factory) this month. While many domestic home appliance companies are relocating most of their production bases to China, Hanil Electric is attracting attention by expanding its domestic production base and producing over 70% of its products domestically.

The top management policy of Hanil Electric, inherited from the late founder Kim Sang-ho, a Zainichi Korean, is national and social service through production. The first product, the automatic pump, was developed by requesting technology transfer from Japan’s Sanyo Electric to improve the domestic situation of water shortage in the 1960s. Subsequently, Hanil Electric established itself as a leading domestic home appliance company with hit products such as the spin dryer ‘Jjalsuni’ and electric fans, which applied pump motor technology.

Park Changjin, Vice President in charge of sales, explains, “Although the workforce has decreased compared to before, we still believe that a company that makes proper electric fans in Korea is essential, so we insist on domestic production.” Hanil Electric produces 300,000 to 500,000 electric fans annually at its domestic factory. Including its affiliates, it employs about 1,000 workers, making it the largest seasonal home appliance company in Korea.

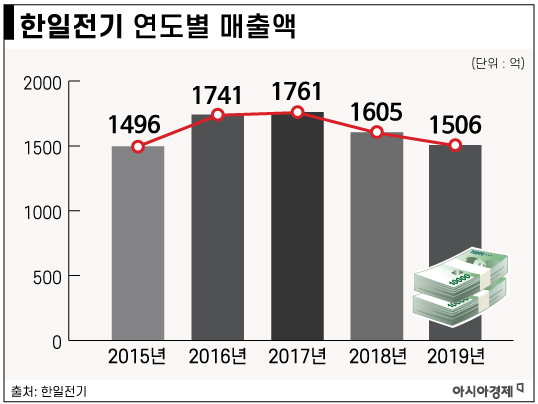

Hanil Electric boasted a solid employment and financial structure, having avoided workforce restructuring even during the foreign exchange crisis, but soon faced a crisis as cheap Chinese products flooded the domestic market. Vice President Park said, “Companies switching to Chinese OEM products recorded sales exceeding 150 billion KRW with about 100 employees. We generate 150 billion KRW in sales with 1,000 employees, which might have seemed inefficient from a management perspective, but the management philosophy was to ‘maintain domestic production.’”

The domestic electric fan market is about 4 million units annually, worth 200 billion KRW. Although the seasonal home appliance market is diversifying to include circulators and window-type air conditioners along with general electric fans, most general electric fans are Chinese-made. Park explained, “Since domestic general electric fans cannot compete with Chinese products on price, many companies are producing through Chinese OEMs. Domestic products are being developed toward circulators, DC fans, and baby breeze fans that allow delicate airflow control.”

Hanil Electric, which overcame the crisis by selling shares it had secured as a major shareholder during the establishment of Shinhan Bank in the 1980s, is attempting new changes with the completion of the new Bucheon factory this month. Established in 1964, Hanil Electric’s Bucheon factory site was partly incorporated into a residential area, making expansion or renovation difficult, and production was carried out in aging facilities. With part of the factory collapsing and no proper repairs for 40 years, plans to relocate the factory overseas were underway, but with the involvement of Bucheon City, the Ministry of Land, Infrastructure and Transport, the Ministry of the Interior and Safety, and the Ministry of Trade, Industry and Energy, the factory was selected as the first regulatory reform target in 2016, finally allowing the construction of a new factory.

Following electric fans, Hanil Electric has also entered the explosion-proof fan and explosion-proof ventilator markets, enhancing safety, and last year obtained Korea’s first explosion-proof certification, pioneering a new market. Vice President Park added, “Although the market size for explosion-proof fans and ventilators is very small, these products were developed to contribute to industrial safety with domestically made products in a market previously dominated by foreign products.”

Marking its 56th anniversary this year, Hanil Electric’s goal, according to Vice President Park, is to uphold ‘Made in Korea.’ Park stated, “Out of the 4 million unit electric fan market, 500,000 units are produced domestically each year, and 90% of those are products we make. We will do our best to contribute to job creation and economic development through domestic production.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![From Bar Hostess to Organ Seller to High Society... The Grotesque Con of a "Human Counterfeit" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)