[Asia Economy Reporter Kim Jong-hwa] The domestic furniture industry is settling on 'E0'. As eco-friendliness becomes a key survival factor in the furniture industry, companies have 'half willingly, half unwillingly' upgraded to meet the higher standards of the US and Europe compared to domestic certification criteria.

'E0' is one of the environmental certification grades for furniture. The main material used by furniture companies when manufacturing furniture is Medium-Density Fiberboard (MDF). MDF is a board made by bonding sawdust with adhesive, which emits a significant amount of harmful gases such as volatile organic compounds (VOCs) and formaldehyde (HCHO), the latter being known as a major cause of sick house syndrome.

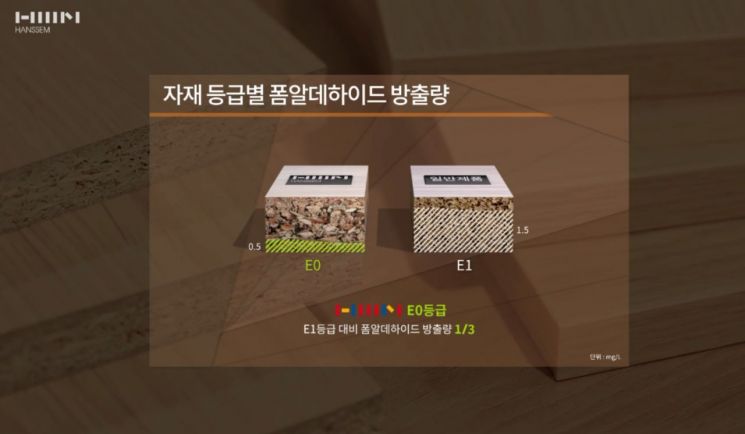

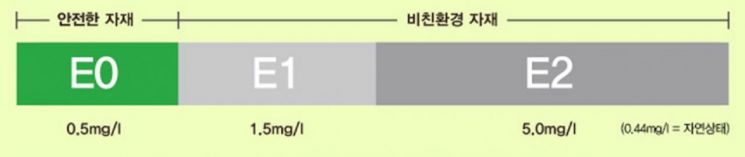

When the Ministry of Environment classifies environmental certification grades for furniture, it divides them into four grades based on HCHO emission levels: SE0 (Super E0), E0, E1, and E2. In Europe and the US, only E0 grade or higher is allowed for indoor furniture, but in Korea, E1 grade or higher with HCHO emissions of 1.5 mg/L or less is permitted for indoor furniture use.

Just 10 years ago, E1 and E2 materials were abundant, but in recent years most companies have upgraded to E0 materials. E0 grade materials emit about 70% less formaldehyde than E1 grade, but are 10-15% more expensive. Why have domestic companies raised their environmental grade by paying additional costs?

In 2014, the global furniture company IKEA entered the domestic market, changing the market landscape. With DIY products where consumers assemble parts themselves rather than finished furniture, IKEA captured young consumers and began to encroach on the domestic market. Domestic furniture companies then criticized IKEA, saying "they sell at higher prices than other countries and the quality is inferior."

However, it became known that all IKEA furniture uses only the most eco-friendly products, SE0 and E0 grades, which backfired on domestic furniture companies. They realized that if they lost in marketing strategy and brand value and also had inferior quality, survival itself would be difficult.

Companies that had been moving quickly even before IKEA's arrival accelerated eco-friendly product development, while those that had been relatively slow felt the pressure. Pursis and Hyundai Livart were in the former group, while Hanssem, Casamia, and Enex were in the latter.

The first to move was Pursis. Since 2011, Pursis has used E0 grade materials in all products. The adhesives and water-based paints used in the manufacturing process are also all eco-friendly products. With this swift action, Pursis became the first domestic company to obtain the global eco-certification 'GREENGUARD' for all self-produced items.

Hyundai Livart established the 'Environmental Technology Center' in 1995, the first domestic organization specializing in eco-friendly product verification and durability testing. To date, it has developed 74 types of eco-friendly adhesives and paints, conducted over 20,000 harmful substance evaluation tests, and has been benchmarked by hundreds of visitors from 12 countries including Vietnam.

Hyundai Livart applied the E0 grade to furniture products from the year IKEA entered the domestic market. Now, it also helps improve the eco-friendly technology of small and medium-sized partners by providing free harmful substance evaluations using its own measurement equipment.

Latecomers Casamia and Hanssem also joined the E0 ranks belatedly. Casamia started using E0 grade materials for all furniture products in 2016, and Hanssem from July 2018. Enex still mixes E0 and E1 grade materials in its online mall but is gradually increasing the proportion of E0 grade.

However, some partner companies and small businesses still mainly use E1 grade, and it is reported that some small businesses still supply E2 grade to the market. Notably, brand companies continue to invest in research and development despite declining sales.

According to the Financial Supervisory Service, the total R&D expenses of furniture companies Hanssem, Hyundai Livart, and Enex last year amounted to 32.56 billion KRW, an increase of about 2% compared to the previous year. Hanssem invested a whopping 29.1 billion KRW in R&D last year, which accounts for 1.81% of its sales (1.6984 trillion KRW).

Hyundai Livart invested 0.26% of sales, and Enex 0.1% in R&D. The industry speculates that the actual R&D investment by these companies is more than twice the reported amount, considering that costs for eco-grade measurement and environmental verification are not included in R&D expenses.

In the past, investment in eco-friendliness was 'half willingly, half unwillingly,' but now it means 100% voluntary investment in eco-friendliness. An industry insider said, "Domestic companies were not neglectful of eco-friendliness, but IKEA's arrival was indeed a stimulus," adding, "With eco-friendliness gaining renewed attention due to COVID-19, domestic companies will no longer be absolutely inferior in quality."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)