[Asia Economy Reporter Hwang Yoon-joo] There is a claim that the servitization of manufacturing is urgently needed to innovate and strengthen the competitiveness of our manufacturing industry.

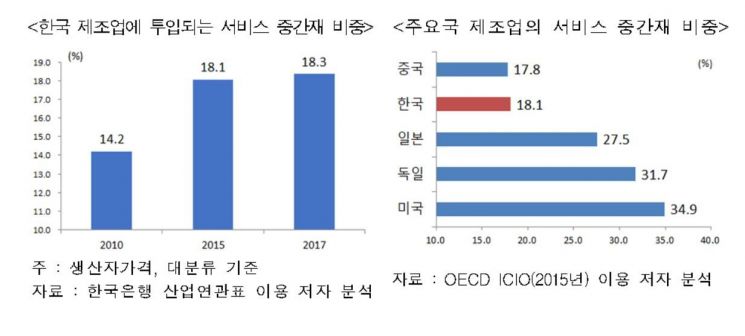

According to the "Current Status of Servitization in Korean Manufacturing and Overseas Expansion Cases" released on the 1st by the Korea International Trade Association's International Trade and Commerce Research Institute (Director Shin Seung-kwan), the proportion of service intermediate goods input into domestic manufacturing increased from 14.2% in 2010 to 18.3% in 2017. As manufacturing companies pursue servitization to increase the added value of products and create new markets, related export cases are also increasing.

The report analyzed cases of service exports by manufacturing companies and classified them into three types: ▲ sales of production technology ▲ sales of product services ▲ high value-added products.

Recently, manufacturing companies are exporting not only tangible products but also intangible technologies that were previously recognized only as means of production. Pharmaceutical companies export new drug substance manufacturing technologies, furniture companies export product designs, heavy industries export shipyard and oil tanker blueprint licenses, and healthcare companies enhance competitiveness by selling software (SW) such as diagnostic programs utilizing hardware (HW) products and user data.

As consumer preferences shift from 'ownership' of products to 'usage,' companies are also transitioning from selling products to selling product functions and services. This phenomenon is particularly active in fields such as water purifiers, air purifiers, and automobiles, where product rentals and sharing economy models are prevalent. Additionally, by providing maintenance services when selling products, companies have increased product added value, and through the establishment of service centers, overseas expansion of services such as product usage training, problem diagnosis, and repairs has also become active.

The report pointed out, "Although servitization of our manufacturing industry is spreading in various forms, it is still insufficient compared to the level of servitization in major countries such as the United States, Germany, and Japan," and added, "While global manufacturing companies are adopting innovative service models, our companies remain limited to providing simple product-related services, so improvement is urgent."

Shim Hye-jung, senior researcher at the Korea International Trade Association's International Trade and Commerce Research Institute, emphasized, "In a situation where the gap in manufacturing technology between countries is narrowing and product differentiation is becoming difficult, servitization of manufacturing is the key to creating new revenue," and added, "The government should actively support the cultivation of upstream and downstream manufacturing support services such as design, engineering, and planning, as well as investment in related research and development (R&D) and expansion of specialized personnel to foster a manufacturing-service convergence ecosystem."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.