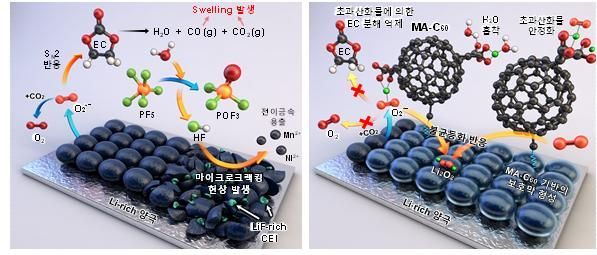

A diagram comparing the issues of using electrolytes in lithium-ion batteries and the functions of new additives.

A diagram comparing the issues of using electrolytes in lithium-ion batteries and the functions of new additives.

[Asia Economy Reporter Hwang Junho] Just as antioxidant enzymes capture reactive oxygen species (ROS), the main culprit of human aging, an electrolyte additive that removes ROS, the main cause of lithium-ion battery aging in electric vehicles, has been developed. It is expected that batteries that can be used longer and more safely can be developed.

On the 30th, Ulsan National Institute of Science and Technology (UNIST) announced that a research team composed of professors Namsoon Choi, Hyungon Song, and Sangkyu Kwak from the Department of Energy and Chemical Engineering developed an electrolyte additive (MA-C60) that removes ROS generated at the cathode of lithium-ion batteries and water that causes side reactions inside the battery.

Extending Electric Vehicle Battery Life by Removing Reactive Oxygen Species

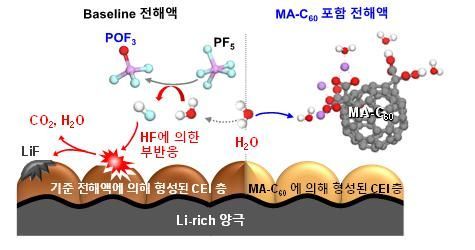

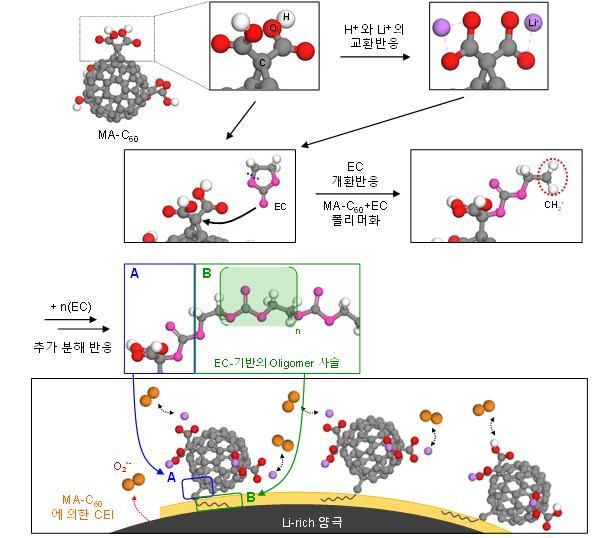

The MA-C60 developed by the research team is a material in which malonic acid is bonded to a fullerene additive and added to the existing electrolyte. When a small amount of this material is added to the electrolyte, it reacts with ROS instead of the electrolyte solvent, preventing the electrolyte from decomposing. At the early stage of battery operation, the additive reacts with the solvent to form a protective film, thereby protecting the cathode surface.

MA-C60 also effectively removes moisture inside the battery. Moisture generated during battery operation decomposes the electrolyte salt (LiPF6), producing acidic compounds (HF) and electrode films (LiF) that shorten battery life and performance. The acidic compounds attack the electrode surface, causing transition metals (lithium, nickel, etc.) that determine battery capacity to leak out. The film formed on the electrode surface causes battery overheating.

Applicable to Other Cathode Materials

Professor Hyungon Song said, "Our body also performs 'antioxidant action' where different enzymes react with ROS to eliminate them," adding, "We developed an electrolyte with a new material (MA-C60) that allows ROS inside the battery to be removed by reacting with other substances."

Professor Namsoon Choi stated, "The electrolyte developed this time is a multifunctional electrolyte that not only removes ROS and moisture causing side reactions in the battery but also forms a protective film on the cathode surface," and predicted, "It can be applied not only to lithium-rich cathodes but also to other high-capacity cathode materials to simultaneously improve the performance and lifespan of high-capacity batteries such as electric vehicle batteries."

The research results were published in the international materials science journal 'Advanced Energy Materials.'

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)