[Asia Economy Reporter Junho Hwang] Domestic researchers have developed a technology that extends the lifespan of hydrogen fuel cells by applying a technique used to remove caffeine from coffee.

The National Research Foundation of Korea announced on the 1st that Professor Yonghoon Cho of the Department of Energy Engineering at Kangwon National University, Professor Changhyun Lee of Dankook University, and Research Team Leader Yeongeun Sung of the IBS Nanoparticle Research Division at Seoul National University developed a technology to improve the lifespan of hydrogen fuel cells by applying ionomers in a supercritical fluid state.

Enhancing Hydrogen Fuel Cell Functionality with Supercritical Fluid Ionomers

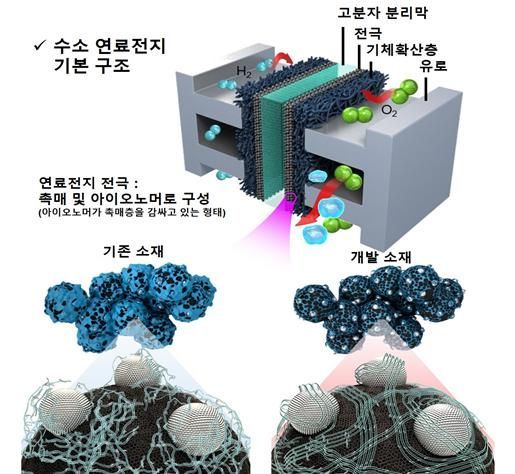

Schematic Diagram of Basic Structure of Hydrogen Fuel Cell and Electrode Materials Developed under Supercritical Conditions

Schematic Diagram of Basic Structure of Hydrogen Fuel Cell and Electrode Materials Developed under Supercritical Conditions

The research team enhanced the performance of hydrogen fuel cells by utilizing ionomers in a supercritical fluid state.

The supercritical fluid state refers to a condition where the density is close to that of a liquid, but the viscosity is similar to that of a gas. Supercritical carbon dioxide is used to remove caffeine from coffee. It is also employed to extract unwanted substances with high purity from fragrances in pharmaceuticals or cosmetics.

In hydrogen fuel cells, which generate electricity through the reaction of hydrogen and oxygen, the team treated ionomers that transport hydrogen ions inside the catalyst under high temperature and high pressure to achieve a supercritical fluid state. The average particle size of the ionomers was reduced to 1/25, significantly enhancing the conductivity of hydrogen ions. The ionomers diffused rapidly with gas-like viscosity and exhibited high solubility with liquid-like density. The research team stated that ionomers in the supercritical fluid state conducted ions up to 1.83 times faster than conventional ionomers.

Improved Durability of Hydrogen Fuel Cells

The research team also applied this technology to actual hydrogen fuel cells. As a result, the dispersion within the electrodes improved, and durability increased sixfold, suggesting that this technology could be used to extend the replacement cycle of fuel cell systems in the future.

The team explained, "This technology enables the mass production of ionomers with uniform properties, significantly reducing the production cost of ionomers. It can be applied to currently commercialized hydrogen fuel cell vehicles and fuel cell power generation facilities."

This research was supported by the Ministry of Science and ICT and the National Research Foundation of Korea through the Climate Change Response Technology Development Project. The research findings were published on the 1st in the international journal Science Advances.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)