Development of a New Triboelectric Nanogenerator Material

Overcoming the Structural Limitations of PVDF

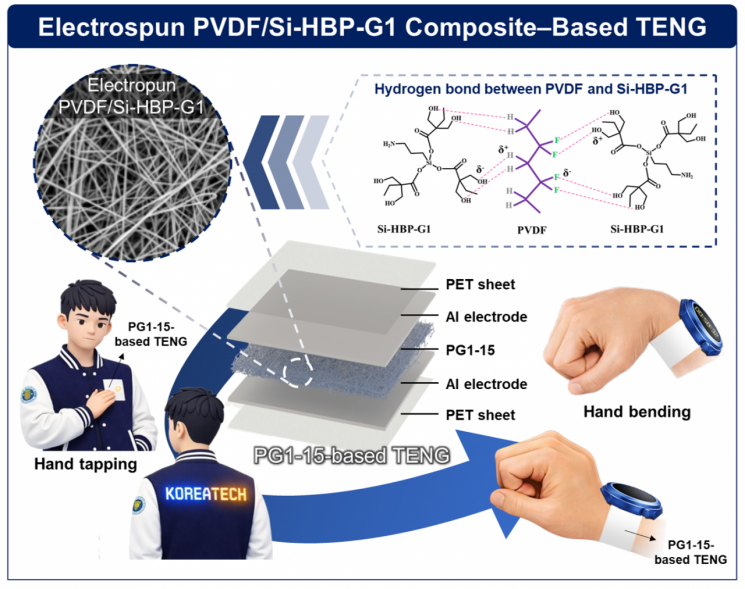

Schematic of TENG Based on PVDF/Si-HBP-G1 Electrospun Fiber Composite / Hankyong National University

Schematic of TENG Based on PVDF/Si-HBP-G1 Electrospun Fiber Composite / Hankyong National University

A research team at Korea University of Technology and Education has developed a new triboelectric nanogenerator (TENG) material that improves the structural limitations of PVDF, a standard power source material, boosting output performance by up to three times.

The university announced on January 20 that Professor Bae Jinwoo and his team from the Department of Energy and Advanced Materials Chemistry have developed a new high-output triboelectric nanogenerator material through international collaboration with Vellore Institute of Technology (VIT) in India.

According to the research team, triboelectric nanogenerators are devices that convert static electricity generated during the contact and separation of materials into electrical energy. They can serve as power sources for IoT sensors and wearable devices that operate without batteries. However, conventional PVDF-based materials have limitations in forming the electroactive β-phase, restricting improvements in output.

The team applied a structural control method by combining PVDF with a silicon-based hyperbranched polyester (Si-HBP-G1). This polymer forms hydrogen bonds with PVDF and disperses uniformly, resolving the aggregation issues seen in previous inorganic nanoparticle approaches.

The newly developed material achieved an open-circuit voltage of 76V, a short-circuit current of 2.1A, and a power density of 0.035W/㎡. Compared to pure PVDF, this represents a 3.5-fold increase in voltage and a threefold increase in current. In practical device experiments, it was able to simultaneously light 40 LEDs and power a digital stopwatch.

Molecular dynamics (MD) simulation analysis showed that the addition of Si-HBP-G1 doubled the β-phase transition rate of PVDF and increased the β-phase content from 78.1% to 85.4%. The research team analyzed that the branched polymer structure promotes PVDF chain alignment, thereby enhancing charge generation efficiency.

Professor Bae Jinwoo stated, "We have demonstrated that PVDF performance can be significantly improved through polymer structure control alone, without the need for complex inorganic additives."

This research was supported by the Mid-Career Researcher Program of the Ministry of Science and ICT and the National Research Foundation of Korea, the Ministry of Education's BK21 Program, and the Ministry of Trade, Industry and Energy's Materials and Components Technology Development Program. The results were published in the latest issue of the international journal Advanced Composites and Hybrid Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)