Competition Heats Up for Market Leadership in "GW-Class" HVDC

Key Technology Advances Ahead of Saemangeum?Seohwaseong Demonstration

Race for Speed in Privately Led Valve and Control Device Sectors

Hyosung Heavy Industries has reportedly achieved a virtual success in localizing the valve, one of the core components of 2GW-class voltage source high-voltage direct current (HVDC) technology. The valve is a power device that converts alternating current (AC) and direct current (DC) back and forth. While the company had previously applied this technology to 200MW-class voltage source HVDC, this is the first time in Korea that a company has developed a 2GW-class valve, which is considered much more technically challenging. As the environment becomes more favorable for renewable energy transmission, this achievement is expected to make a significant contribution to the localization of the energy superhighway project promoted by the government.

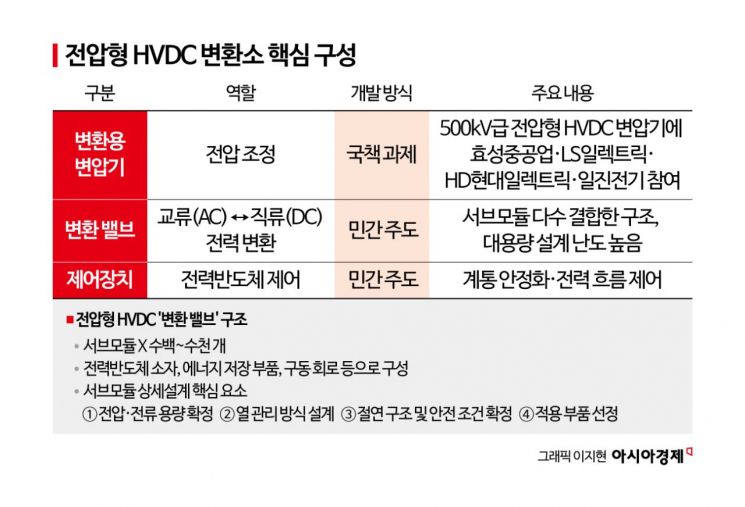

According to industry sources on December 14, Hyosung Heavy Industries recently completed the detailed design of the "submodule," a key component of the 2GW voltage source HVDC valve. A company representative stated, "We have now completed the detailed design of the submodule," and added, "The localization of related technologies, including the development of other components, is also progressing as planned." The detailed design stage involves finalizing specific details such as voltage and current capacity, thermal management methods, insulation structure, and the components to be applied, so that the submodule can actually be manufactured.

Previously, Hyosung Heavy Industries developed a 200MW-class voltage source HVDC and installed the system at Korea Electric Power Corporation's Yangju substation last year. Building on this experience, the company has spent the past two years working on scaling up the technology for 2GW applications, and has now nearly secured the 2GW valve technology.

The HVDC system consists mainly of a converter transformer, a valve, and a control device. The converter transformer adjusts the voltage, the valve is a power electronics device that converts AC and DC, and the control device manages the power conversion process by controlling the operation of the power semiconductors inside the valve. Currently, converter transformers are being developed by four major domestic power companies, including Hyosung Heavy Industries, as part of a government-led national project, while the valves and control devices are being developed independently by each company in the private sector.

In particular, the submodule developed by Hyosung Heavy Industries combines power semiconductor devices, energy storage components, and drive and protection circuits. The valve is composed of hundreds to thousands of submodules to form a "valve tower," which converts large amounts of power. Since the submodule design conditions serve as the standard for the overall valve configuration and control method, detailed submodule design is considered a key stage in the valve development process.

The 200MW-class high-voltage direct current (HVDC) system supplied by Hyosung Heavy Industries to the Korea Electric Power Corporation's substation in Yangju, Gyeonggi Province. Hyosung Heavy Industries

The 200MW-class high-voltage direct current (HVDC) system supplied by Hyosung Heavy Industries to the Korea Electric Power Corporation's substation in Yangju, Gyeonggi Province. Hyosung Heavy Industries

Scaling up power equipment is considered an essential task, given the increasing scale of power transmission. HVDC converts AC power to DC for long-distance, high-capacity transmission. Among these, voltage source HVDC, unlike the conventional current source method, uses power semiconductors to actively control the flow of electricity. It is evaluated as advantageous for renewable energy integration and grid stabilization. However, as the capacity of the equipment increases, the technical difficulty of the electrical and thermal design and control technology of the conversion equipment also increases.

In particular, HVDC-related technology is classified as a highly advanced field in which only a few companies-namely GE Vernova of the United States, Siemens Energy of Germany, and Hitachi Energy of Japan (formerly the ABB Power Grids division of Sweden)-have commercial references and are considered the global "big three." By securing valve technology, Hyosung Heavy Industries has taken a significant step toward reaching the global level.

If localization of the control device is also achieved following the transformer and valve, it is expected that the government-led 2GW-class voltage source HVDC demonstration project will be able to use domestically produced equipment. The demonstration section is the Saemangeum~Seohwaseong segment (approximately 220 km). The government plans to establish a special purpose company (SPC) by the end of 2026 and aims to complete the demonstration line by 2030. In parallel with the demonstration project, the localization development of key equipment is also underway.

Other companies are also accelerating their technology development efforts. In July, LS Electric signed a memorandum of understanding (MOU) for technical cooperation with GE Vernova to localize voltage source HVDC converter valves. LS Electric has experience in producing "current source" HVDC valves and valves for static synchronous compensators (STATCOM).

According to global market research firm Fortune Business Insights, the global HVDC converter station market is estimated to be worth about $13.68 billion (approximately 20.1 trillion won) in 2024, and is expected to grow to about $30.41 billion by 2032. The market is projected to grow at an average annual rate of about 10.9% during this period.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)