A technology has been developed that enables the production of high-quality graphene under ultra-low temperature and ultra-fast conditions.

The National Research Foundation of Korea announced on December 1 that a research team led by Professor Geum Hyunseong of Yonsei University, Professor Lee Taehun and Professor Park Hongsik of Kyungpook National University, and Professor Kim Sungkyu of Sejong University succeeded in producing high-quality graphene, nearly single-crystalline, at temperatures below 500 degrees Celsius without damaging the substrate surface.

A single crystal refers to a structure in which the atoms or molecules throughout the entire solid mass are arranged in a continuous and regular pattern. This property is essential for manufacturing semiconductor substrates that require uniform electrical characteristics.

The joint research team's technology enables the production of high-quality graphene on a silicon carbide (SiC) substrate under ultra-low temperature and ultra-fast conditions, making it possible to manufacture next-generation semiconductor thin films such as gallium nitride (GaN) and aluminum nitride (AlN).

Recently, demand for high-performance nitride (GaN, AlN) semiconductors has been rapidly increasing, particularly in the fields of power semiconductors, high-frequency devices, and micro LED applications.

However, in order to create the optimal substrate that allows easy separation of nitride semiconductors from the substrate (a technology that peels off the semiconductor layer from the substrate for substrate reuse), it is necessary to graphitize the SiC substrate at high temperatures above 1,500 degrees Celsius.

Even after undergoing this ultra-high temperature process, the SiC substrate surface becomes rough and the graphene thickness becomes uneven. Additionally, since it is difficult to reuse the expensive SiC substrate, there is a need to change the manufacturing process to facilitate industrial expansion.

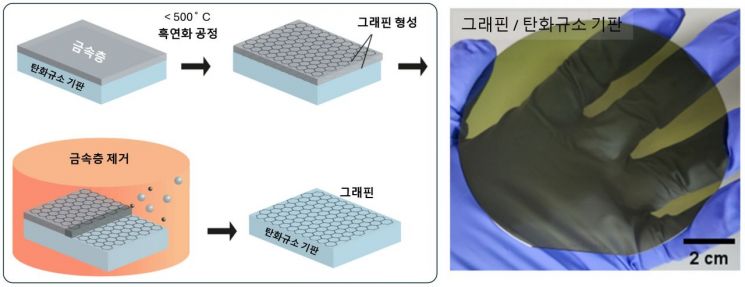

In contrast, the technology developed by the joint research team enables the production of high-quality graphene at temperatures below 500 degrees Celsius without damaging the substrate surface.

The key material that enabled the low-temperature process is nickel (Ni) metal. The research team discovered that introducing nickel as a metal catalyst stabilizes the energy conditions when carbon rearranges into the graphene structure. Based on this, by controlling the nickel thickness and temperature, they demonstrated that monolayer to bilayer graphene can be formed within seconds at 320 degrees Celsius, and multilayer graphene at 500 degrees Celsius.

The low-temperature process allows the SiC substrate surface to remain atomically smooth, enabling the final semiconductor thin film to achieve much higher crystallinity compared to high-temperature processes.

This nickel-based low-temperature process can also be effectively applied to next-generation semiconductor technology, specifically the '2D-based epitaxy' method (a semiconductor technology that grows oriented single-crystal thin films on a crystalline substrate). This means that expensive SiC substrates can be reused and heterogeneous material integration is possible. In fact, the joint research team confirmed that semiconductor thin films produced by the nickel low-temperature process could be detached and reattached like a sticker, leaving no trace on the substrate.

Professor Geum stated, "The joint research team has proposed a solution for substrate reuse and manufacturing cost reduction through a graphene production technology that works at low temperatures," adding, "This will serve as an important theoretical basis for future research on low-temperature-based 2D material synthesis and heterogeneous epitaxy."

This research was supported by the Basic Research Laboratory Program promoted by the Ministry of Science and ICT and the National Research Foundation of Korea. The research results (paper) were published online in the international journal Science Advances on November 21.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)