Inside the Apple Manufacturing R&D Support Center in Pohang

Free Consulting and Testing Equipment for Manufacturing SMEs

Component Analysis Reveals Surface Substances on Dried Squid

Jointly Operated by Apple and POSTECH, Supporting Over 1,100 Cases

"It was unexpected for us to receive support from a major American tech company like Apple. As a small business owner, the cost of testing and inspection can be a burden, but with the help of the support center, we were able to receive free inspections and even analysis."

Apple is supporting manufacturing small and medium-sized enterprises (SMEs) in Korea with advanced technology. This is being done through the Manufacturing R&D Support Center, which is jointly operated with Pohang University of Science and Technology (POSTECH). Through this center, Apple not only shares its expertise with SMEs in the manufacturing sector but also provides support for testing and analysis.

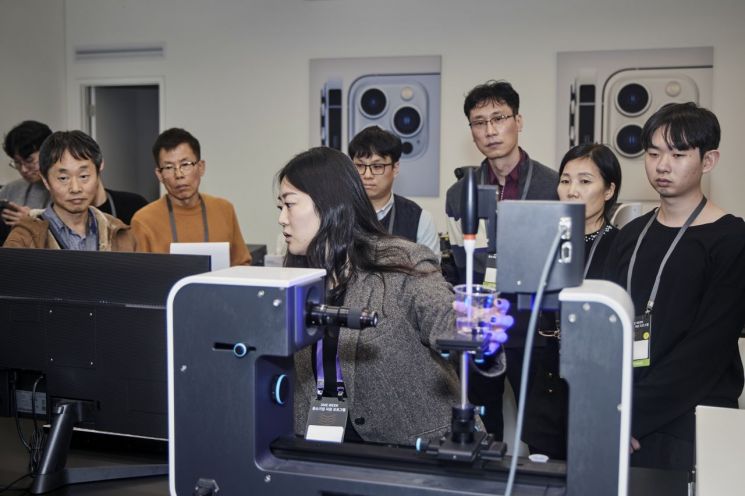

Participants are touring the analytical laboratory equipment inside the Apple Manufacturing R&D Support Center during the SME WEEK event co-hosted by the Apple Manufacturing R&D Support Center and Pohang University of Science and Technology from the 25th to the 27th. Photo by Apple Manufacturing R&D Support Center

Participants are touring the analytical laboratory equipment inside the Apple Manufacturing R&D Support Center during the SME WEEK event co-hosted by the Apple Manufacturing R&D Support Center and Pohang University of Science and Technology from the 25th to the 27th. Photo by Apple Manufacturing R&D Support Center

Haneolmulsan, established in 2016, is a company that processes seafood such as squid. The company received help from the support center to analyze the white powder that forms on the surface of dried squid. Shin Seunghan, CEO of Haneolmulsan, whom we met at the support center located inside POSTECH on the 27th, said, "Some customers asked whether the white powder on dried squid was mold, so we reached out to the support center to request a component analysis."

In response to Mr. Shin's request, the support center used its component analysis equipment to identify that the powder was taurine. Taurine, which is present in the squid's bodily fluids, crystallizes as a white residue on the surface during the drying process. Taurine is known to be beneficial for blood circulation and liver protection. Thanks to these analysis results, Haneolmulsan was able to explain the product's quality to its clients. The inspection, which would have cost at least several hundred thousand won if commissioned to a private testing agency, was conducted free of charge.

Mr. Shin said, "For small businesses like ours, we often don't even know where to get such inspections, and the cost can be a real burden. The support center not only provided free testing but also consulting, which was a great help," adding, "Going forward, I would also like to use the support center's help to set the product's shelf life clearly based on data."

The Apple Manufacturing R&D Support Center opened in 2022 as part of Apple's initiative to foster mutual growth with domestic SMEs. Apple and POSTECH engineers are stationed at the center to provide Korean manufacturing SMEs with opportunities to upgrade their technology, processes, and products. The center offers consulting and educational programs for business or process improvement, as well as analytical services using its own testing equipment. All consulting, education, and services are provided completely free of charge. This is the first-ever 'global No. 1' Manufacturing R&D Support Center established by Apple. Subsequently, Apple has also opened support centers at locations such as the University of Michigan in the United States.

Shin Seunghan, CEO of Haneolmulsan, is being interviewed by The Asia Business Daily on the 27th at the Apple Manufacturing R&D Support Center in Pohang, Gyeongbuk. Photo by Apple

Shin Seunghan, CEO of Haneolmulsan, is being interviewed by The Asia Business Daily on the 27th at the Apple Manufacturing R&D Support Center in Pohang, Gyeongbuk. Photo by Apple

The laboratory inside the center, which the reporter visited that day, was filled with various precision testing instruments. In addition to the component analysis equipment used for Mr. Shin's request, there were a variety of ultra-high-precision measuring devices. Precision testing equipment typically costs from several billion to several tens of billions of won per unit, but the results of tests and analyses using these devices are provided free of charge.

Not only Haneolmulsan but also various manufacturing SMEs from across the country come to Pohang for process consulting, specialized training, or to use the testing equipment. According to the support center, since its opening in 2023, a total of 2,320 trainees have visited, and the number of cases where consulting or analytical equipment was provided exceeds 1,100. Semiconductor manufacturer ENT received help from the center's engineers to improve defects that occurred during product development, and Seven Treasures, a traditional fermented food producer specializing in products like meju, introduced the latest processing and wireless transmission technology into their production process with the support center's assistance.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)