Real-Time Monitoring of Manufacturing Facilities with AI Technologies

Supporting Process Hazard Analysis and Industrial Accident Reporting

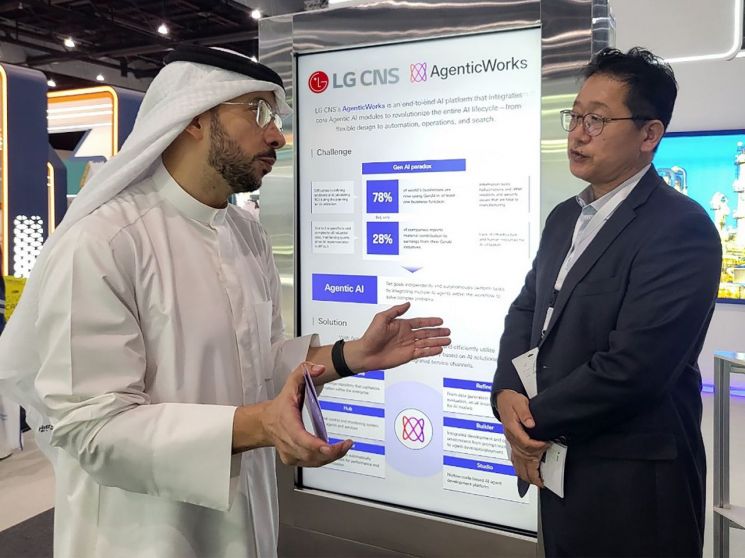

Hyun Shingyun: "Accelerating Global Business Innovation"

LG CNS is targeting the Middle Eastern market with artificial intelligence transformation (AX) technologies specialized for manufacturing sites.

From September 30 to October 2, LG CNS is participating in IDCE 2025, held in Bahrain, to showcase its "Manufacturing AX" technologies, which enable the intelligence and automation of oil industry sites.

IDCE is the largest industrial exhibition in the Middle East, often referred to as the "CES of the oil and refining industry." The event is organized by the Gulf Downstream Association (GDA), which was established by six leading Middle Eastern companies that drive the global petrochemical market, including Saudi Aramco and Bahrain Petroleum Company (BAPCO). This year, companies from around 50 countries participated, introducing innovative technologies for the oil and refining industries as well as sustainable energy solutions.

LG CNS, together with S-OIL, set up an exhibition booth under the theme of "AI-based Intelligent Plant Transformation," showcasing solutions such as the Flare Stack Optimization System, the Process Hazard Analysis AI Agent, the Process Safety Management (PSM) AI Tutor, and the AI Incident Reporting System. These technologies, which simultaneously enhance essential safety management and productivity at manufacturing sites, attracted significant interest from industry clients.

The flagship solution, the Flare Stack Optimization System, is a system that provides 24/7 uninterrupted monitoring of flare stacks-facilities that safely burn and discharge flammable gases-using AI video analysis technology and AI CCTV. The AI detects anomalies by analyzing the color of the smoke and the state of the flames, and automatically controls devices such as steam valves to maintain optimal conditions, thereby improving process stability.

LG CNS also introduced an AI agent that automates the analysis of facility diagrams for process hazard analysis. Process hazard analysis is conducted during the design or completion stages of production facilities to identify potential risks in advance. Traditionally, the entire process was done manually, which was time-consuming and resulted in varying outcomes depending on the worker’s level of expertise. By utilizing the Process Hazard Analysis AI Agent, the AI automatically analyzes all facility diagrams and specifications within the plant, reducing average analysis time by more than 60% and significantly improving the accuracy of the assessments.

The AI Incident Reporting System automates the reporting and notification process in the event of industrial accidents such as fires or casualties, thereby accelerating initial response times. When the first witness sends site photos and voice memos via a mobile app, the AI analyzes the data to infer the type, severity, and potential causes of the incident, and handles everything from report generation to in-house notifications and official safety authority reporting in one streamlined process.

Since signing a business agreement for building intelligent factories in February this year, LG CNS and S-OIL have been continuously pursuing projects to apply AX technologies at oil and refining industry sites.

At this event, LG CNS CEO Hyun Shingyun met with Hussein Al Qahtani, Head of Refining at Aramco, to discuss cooperation plans for embedding AX technologies at Aramco, based on LG CNS’s successful manufacturing AX cases.

CEO Hyun stated, "AI-based plant intelligence is the core driver of innovation in the manufacturing industry," adding, "We will do our utmost to accelerate business innovation and transformation for global clients, based on AX technologies and proven success cases that can be immediately applied to actual manufacturing sites."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.