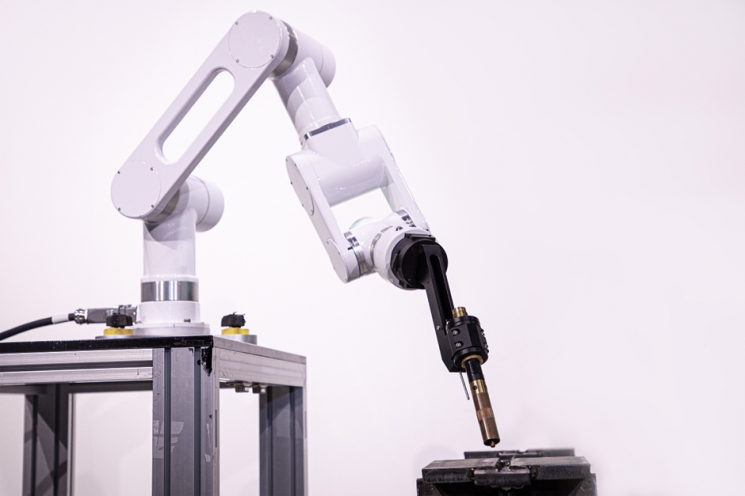

NeuroMeka, a company specializing in robotic automation, has unveiled its welding-specialized collaborative robot, "OPTi3."

On September 30, NeuroMeka announced that it had signed a supply contract for the OPTi3. As the second model in the OPTi series, OPTi3 has been confirmed for introduction at a major global shipyard in South Korea, following the previous OPTi5 model.

Optimized for the shipyard welding domain, the model continues to build a track record of successful deployments. NeuroMeka previously signed a contract worth approximately 1.6 billion won with HD Hyundai Robotics, supplying 12 collaborative robots for the panel slit welding process at HD Hyundai Samho Shipyard. This marked the first case in Korea where a system combining collaborative robots and autonomous mobile robots (AMR) was introduced to this process, demonstrating the innovation and field reliability of the OPTi series.

The OPTi series is NeuroMeka’s line of collaborative robots specialized for welding, focusing on lightweight design, symmetrical structure, and easy mobility. It is optimized for confined workspaces and left-right symmetrical work environments, minimizing installation time and movement paths. The OPTi series offers two models-OPTi3 and OPTi5-depending on payload capacity.

OPTi3 features a lightweight design with a total weight in the 10kg range and an integrated ergonomic handle, allowing operators to easily carry and reposition the robot. It can also be modified to a five-degree-of-freedom structure, reducing the total weight to the 9kg range and enhancing singularity avoidance performance. Materials and colors suitable for welding environments have been applied to minimize contamination and discoloration. The robot’s end can be equipped with specialized welding tools, enabling quick attachment and detachment of welding torches and smooth process transitions. From design to function, the entire OPTi series is optimized for welding operations, focusing on improving both quality and productivity in the field.

The core area of cooperation in the Korea-U.S. shipbuilding partnership project "MASGA" is the maintenance, repair, and overhaul (MRO) of naval vessels. Since the targeted ships are mostly small- and medium-sized, frequent posture changes and equipment relocations in tight spaces are essential. In such environments, OPTi3 maximizes its ultra-lightweight, symmetrical, and portable design to reduce deployment and transition times, while minimizing movement paths for left-right transitions during welding. This greatly enhances practical usability.

The shortage of skilled welding personnel and limited supply of lightweight robots across the United States and Korea present new opportunities for OPTi3, which can flexibly handle various variable tasks.

Park Jonghun, CEO of NeuroMeka, stated, "With the continued success of OPTi3 following the delivery record of OPTi5 to shipyards, the OPTi series is establishing itself as the standard reference for welding automation in shipbuilding."

He added, "Starting with the MASGA project, NeuroMeka will expand the application of its dual lineup of OPTi3 and OPTi5 to the global shipbuilding market, including small- and medium-sized vessels. We aim to set a new standard for field-oriented, optimized welding automation."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)