[Hyundai Motor Company, Over the Mobility] (34)

Hyundai Motor Company's Extraordinary Inventions

Nano Cooling Film That Lowers Interior Temperatures

Self-Healing Technology That Eliminates Scratches and Scuffs

Cars That Clean Raindrops Off The

Cars are no longer just simple means of transportation. At Hyundai Motor Company and Kia Corporation's research centers, in-house ventures, and startup sites, technologies that once seemed fit for science fiction are being developed, and vehicles are evolving every day.

Technologies such as tinting films that expel heat during the summer, nano coatings that heal scratches on their own, body forming techniques that create sleek and vibrant colors without the need for painting, seat leather made from mushroom mycelium, airless tires, and autonomous robots for last-mile delivery have all been developed and are ready to create the next generation of vehicles.

While these advances may still seem like science fiction, they have emerged out of urgent demands in the automotive industry: responding to environmental regulations, reducing costs, and enhancing safety. As competition over future mobility intensifies, Hyundai Motor Company's experiments are not just driven by curiosity but are survival strategies for tomorrow. Let us follow these extraordinary inventions developed by Hyundai Motor Group researchers and related startups, and imagine how technological progress might transform our daily lives and the future of the automotive industry.

What if your car was already cool inside despite the scorching heat?

In July, at midday in South Korea, when the outside temperature exceeds 25 degrees Celsius, the temperature inside a parked car can soar to as high as 50 degrees Celsius. Just looking at a car baking under the blazing sun can make you feel breathless. As soon as you open the door, a wave of hot air rushes out. The moment you sit in the driver's seat, the heated upholstery wraps around your body. Yet, something feels different. You braced yourself for a sweltering "oven," but it turns out to be bearable. Once the air conditioner is switched on, the interior quickly becomes comfortable.

The secret lies in the "transparent radiative cooling film" applied to the car windows. This film consists of four ultra-thin, invisible layers. It effectively reflects ultraviolet and near-infrared rays-the wavelengths in sunlight that generate heat-while certain layers emit far-infrared radiation produced inside the vehicle back outside. As a result, the interior temperature can be lowered by more than 10 degrees Celsius compared to cars without the film.

Whereas conventional "tinting films" merely blocked sunlight, this technology goes a step further by enabling the car to actively expel heat. Previously, increasing the heat-blocking effect of tinting films meant making them darker, which compromised visibility. This new technology, however, maintains the transparency of the glass while delivering both heat-blocking and heat-emitting benefits.

The industrial significance is also substantial. Cooling a car is one of the main factors that consumes fuel and battery power. If this film becomes widespread, it will extend the driving range of electric vehicles in summer and improve both fuel and energy efficiency. Reduced air conditioner usage will also lower carbon dioxide emissions, helping automakers comply with increasingly strict global environmental regulations.

Hyundai Motor Company conducted a Nano Cooling Film campaign in Pakistan. A driver is touching the vehicle glass coated with the Nano Cooling Film. Photo by Hyundai Motor Company

Hyundai Motor Company conducted a Nano Cooling Film campaign in Pakistan. A driver is touching the vehicle glass coated with the Nano Cooling Film. Photo by Hyundai Motor Company

A scratch from a parking lot pillar disappears overnight-your car heals itself

While backing into a parking space, you accidentally scrape your car against a pillar. From a distance, it's hardly noticeable, but up close, the scratch is quite deep. Although it stings, you decide to wait a day, having opted for a polymer coating with a "self-healing" function just in case.

The next morning, on your way to work, you check and find that the scratch from the previous day has completely vanished. Even minor scratches or damage, if left unattended, can affect the car's condition or safety. If sensors or camera lenses used in advanced driver-assistance systems (ADAS) are damaged, they may not detect signals correctly, and cracks or scratches on the body can lead to corrosion, reducing impact absorption in the event of an accident.

Nano self-healing technology allows the car's surface to recover from scratches, much like human skin regenerates. The special coating contains polymer materials that temporarily separate when damaged, then recombine through reversible chemical reactions to restore the original state. Unlike conventional methods, this process does not require separate catalysts or heat. Its biggest advantage is that it can repeatedly regenerate at room temperature.

Raindrops on the camera lens-your car cleans itself

On a summer day with torrential monsoon rain, the wipers work nonstop to clear the windshield. With visibility poor, you activate the advanced driver-assistance system (ADAS). You wonder if the semi-autonomous driving feature will work properly in such weather, but you decide to trust the technology.

This car is equipped with a special camera sensor cleaning technology called "Rotator-Cam." It removes contaminants by rotating a cover glass in front of the lens. This technique effectively eliminates not only dirt and dust but also moisture on the lens.

Previously, there were two main lens cleaning methods. The first used a pop-up nozzle to spray washer fluid forcefully, but the fluid or raindrops could accumulate and obscure the lens. The second method used a small motorized wiper to directly wipe the lens, which was effective for removing raindrops but could block the camera's view as the wiper moved back and forth.

Hyundai Motor Group's Rotator-Cam technology, developed in 2023, solves these problems. A protective cover glass is placed over the camera lens and rotated, while a fixed wiper cleans the surface. The system also supplies washer fluid, allowing it to remove dust, mud, and water droplets thoroughly. Since the wiper does not move across the lens, it does not obstruct the view.

Additionally, artificial intelligence detects weather and contamination levels, adjusting the amount of washer fluid sprayed and blowing air between the lens and glass to prevent fogging. In autonomous vehicles equipped with dozens of camera sensors, camera performance is directly linked to driving safety. Rotator-Cam technology not only enhances sensor reliability but also helps reduce maintenance costs by minimizing washer fluid use.

Car seats made from mushrooms

As you step into a new car, a subtle leather scent greets you. Running your fingers over the seat, it feels soft and luxurious. At first glance, it seems no different from genuine leather, but in fact, these seats are made from mushrooms, not cowhide.

Worldwide, the development of eco-friendly "mycelium leather" materials that can replace animal leather is gaining attention. Mycelium is the root structure of mushrooms. Its thread-like growth allows it to mimic the texture and strength of real leather. By cultivating mycelium on organic matter such as wood chips or sawdust and processing it through special techniques, it becomes an eco-friendly material with durability and softness comparable to natural leather. Most importantly, it significantly reduces environmental impact during both production and disposal. There is no need to slaughter cattle, chemical processing is minimized, and the waste is 100% biodegradable.

'Mycel,' a startup founded by former Hyundai Motor Company in-house venture employees, specializes in developing eco-friendly leather using mushroom mycelium. The company grew through Hyundai Motor Group's open innovation platform, ZER01NE, and spun off in 2020.

The company's researchers use artificial intelligence to precisely control the cultivation conditions of mycelium, achieving durability and texture on par with natural leather. They have also enabled the creation of various colors and patterns. By meeting eco-friendly certification standards in different countries, the company aims to expand its materials from automotive seats and interior panels to fashion, furniture, and building materials.

In particular, automakers-especially in Europe-are facing stricter regulations requiring them to reduce carbon emissions throughout the entire production process (LCA). Leather seats are a major source of carbon emissions in car manufacturing. By using vegan leather, automakers can reduce methane emissions from livestock and carbon emissions from chemical tanning, significantly lowering the "carbon footprint" per vehicle.

As of 2025, the use of "mushroom leather" in car interiors is limited to certain panels in concept cars. However, as the technology matures rapidly, it may not be long before we see cars with seats grown from mushrooms on the road.

Tires that never go flat

On a Saturday morning, you start your car, only to see the tire warning light on the dashboard. The tires look fine, but checking the pressure reveals that one tire has lost air rapidly. You probably ran over a nail or debris on the road the day before. With no other choice, you visit a nearby repair shop to fix the flat tire, and your weekend plans are inevitably delayed. Most drivers have experienced a flat tire at least once-what if you never had to worry about it again?

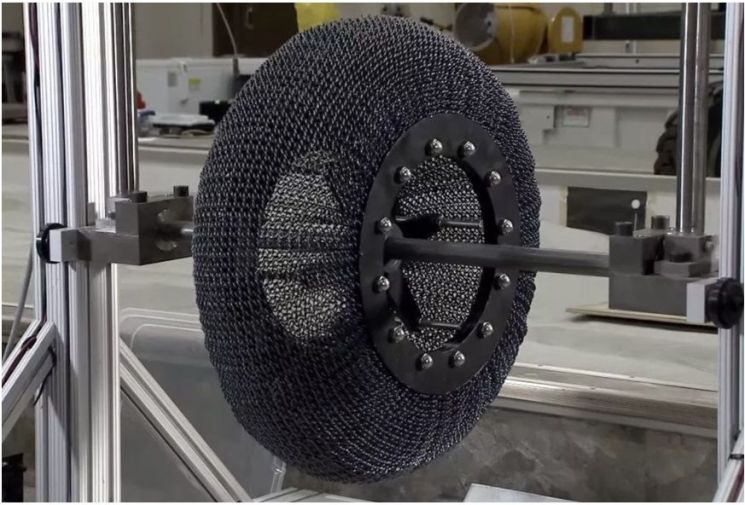

Smart Tire Company, a U.S. startup invested in by Hyundai Motor Group, was founded to solve exactly this problem. The company is adapting tire technology used in NASA's Mars rovers for civilian use, developing "ultra-elastic tires" that require no air. The core technology is NiTinol, a nickel-titanium alloy with shape memory properties. Even if deformed by external pressure, NiTinol returns to its original shape when exposed to heat or shock.

Smart Tire Company weaves this alloy radially to create a new tire structure called "METL." It is as elastic as rubber and as strong as titanium, maintaining its shape without air and making it puncture-proof. At CES 2025, the company unveiled its "airless tire" for bicycles, with visitors noting that its elasticity was almost indistinguishable from conventional rubber tires.

The automotive industry is closely watching this technology. If it proves reliable not only for city driving but also for long-distance travel, drivers will no longer need to visit repair shops for flats or carry spare tires. Reducing the use of rubber and petroleum in manufacturing is also a significant environmental advantage.

Globally, environmental regulations on tires are being tightened. Disposing of used tires emits large amounts of carbon, and tire wear during driving is a major source of fine dust that pollutes the air and soil. The European Union is even considering regulating tire wear particles. Metal-based tires that maintain their shape without air are being recognized as a key innovation for sustainable mobility.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.